Imaginez expédier des vaccins vitaux à travers les continents ou livrer du thon japonais frais à un restaurant parisien. Le héros invisible rendant cela possible? Glace sèche. Cette forme solide de dioxyde de carbone, refroidissement à un givré -78 ° C (-109°F), est devenu le tuteur silencieux de notre chaîne froide mondiale, Assurer que les marchandises sensibles à la température arrivent en parfait état.

Pourquoi la glace sèche règne en maître

Contrairement à la glace traditionnelle qui fond en un désordre aqueux, La glace sèche effectue une astuce magique appelée sublimation - elle se transforme directement de solide en vapeur froide. Cette propriété unique le rend indispensable pour la logistique moderne:

-

Refroidissement puissant: Juste 1 kg de refroidissements de glace sec aussi efficacement que 2 kg de glace ordinaire, sans ajouter un poids d'eau lourde.

-

Capacité de congélation profonde: Maintenir des températures ultra-basses (-50° C à -80 ° C) est crucial pour les produits pharmaceutiques, aliments spécialisés, et matériel de recherche.

-

Opération propre: Comme il se vaporise, La glace sèche ne laisse aucun résidu liquide, Protéger l'électronique sensible et les fournitures médicales.

Mais des défis restent. L'emballage standard gaspille souvent le pouvoir de refroidissement par une mauvaise isolation, conduisant à une perte de glace sèche prématurée et à des fluctuations de température. C'est là que Smart Engineering fait toute la différence.

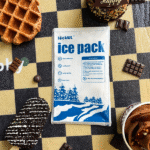

Pack de glace sec tempk: Refroidissement plus intelligent, Avenir durable

Tempk a repensé les emballages de glace sec pour relever les défis de la chaîne froide moderne. Voici comment leur solution se sépare:

-

Performances de refroidissement étendues

Merci à l'isolation aérogel inspirée de l'aérospatiale, Les packs de tempk réduisent la perte de glace sèche jusqu'à 35%. Cela signifie des températures ultra-froides cohérentes pour 72+ heures - suffisamment de temps pour que les vaccins traversent en toute sécurité les océans ou pour la crème glacée premium pour atteindre des marchés éloignés. -

Conception de la planète

Tout en gardant les marchandises froides, Le tempk maintient également son impact environnemental au frais. Leurs coquilles utilisent des polymères à dégradage marin qui se décomposent 5 années, Et le Co₂ à l'intérieur vient des émissions industrielles capturées. C'est la logistique de la chaîne du froid qui s'occupe du climat. -

Surveillance intelligente

Les capteurs intelligents intégrés agissent comme un tuteur numérique, Suivi de la température en temps réel, orientation de la boîte, et les niveaux de glace sec restants. Les alertes connectées au cloud avertissent les gestionnaires de logistique avant les problèmes se produisent, réduisant potentiellement la détérioration de 90%. -

Efficacité adaptable

Pourquoi utiliser une boîte rigide lorsque les expéditions varient? Le système modulaire de Tempk s'adapte pour sécuriser les flacons délicats ou les fruits de mer volumineux dans le même récipient. Rapport des clients 20% Utilisation d'espace plus efficace par rapport aux options traditionnelles.

La révolution de la chaîne froide

À mesure que la demande mondiale de biens sensibles à la température augmente, Des innovations comme les packs de glace sec intelligente de Tempk transforment la logistique d'un centre de coûts en un générateur de valeur. Les sociétés pharmaceutiques expédient désormais des thérapies cellulaires complexes sur les continents, Les restaurants proviennent des ingrédients vraiment frais dans le monde entier, et les laboratoires de recherche reçoivent des spécimens sensibles intacts.

L'avenir semble encore plus brillant. Les technologies émergentes combinent la glace sèche avec des méthodes de refroidissement éconergétiques énergétiques, tandis que les systèmes en boucle fermée capturent et réutilisent le co₂ sublimé. Ce qui a commencé comme un simple dioxyde de carbone congelé est devenu un écosystème de gestion de la température sophistiquée.

Avec l'emballage de glace sec intelligent de Tempk, Les entreprises ne se contentent pas d'expédier froid - ils expédient intelligents, durable, et sécuriser. Dans le monde à enjeux élevés de la logistique de la chaîne du froid, C'est plus qu'un avantage; C'est la tranquillité d'esprit livrée dans chaque parcelle glaciale.