Comment créer une chaîne d'approvisionnement en légumes biologiques à chaîne du froid rentable en 2025

Mis à jour: Décembre 2025

Introduction:

Maintaining freshness and nutritional value from farm to fork is one of the hardest parts of handling organic produce. Un robuste chaîne du froid chaîne d'approvisionnement en légumes bio keeps items within strict temperature ranges, lowers spoilage and meets the growing demand for organic foods. Dans ce guide, you’ll discover how to build a cost efficient supply chain that preserves quality, reduces waste and delights customers. We’ll explore technology, best practices and current market trends for 2025—all in clear language you can act on.

Why proper cold chain management is critical: understand how poor temperature control leads to nutrient loss, spoilage and high costs, and learn how targeted interventions reduce waste.

How to manage temperature and humidity for different vegetables: learn the recommended ranges (0–5 °C for most refrigerated vegetables and −18 °C for frozen stock) and why deviations cause ice crystals and nutrient loss.

Quelles technologies transforment la logistique de la chaîne du froid: explore AI route optimisation, IoT sensors and blockchain for real time monitoring, traceability and efficient routing.

What market trends will shape 2025 et au-delà: see how surging demand for plant based foods, regulatory rules and sustainability goals influence your planning.

Why do Bio Vegetables Need a Reliable Cold Chain?

Cold chain fundamentals: A cold chain is a temperature controlled process encompassing harvesting, conditionnement, stockage, transport et distribution. According to the International Fresh Produce Association, autour 70 % of food consumed in the U.S. flows through cold chains, while in China only about 5 % of fruits and vegetables are handled this way. The cold chain is science, technology and process combined: science to understand perishability; technology to maintain temperature; and process to prepare, store and transport goods. Without consistent cooling, respiration rates remain high, microbes proliferate and produce spoils quickly.

Nutrient loss and waste: The United Nations estimates that about 13 % de la production alimentaire mondiale est perdue en raison de chaînes du froid insuffisantes. En Afrique subsaharienne, more than half of smallholder farmers’ vegetable harvest never reaches market. Poor refrigeration and long transport mean many bio vegetables lose vitamins—vitamin C in broccoli declines rapidly above 5 °C—and consumers pay higher prices to cover losses. De la même manière, les États-Unis. wastes around 25 % of food transported in cold chains due to temperature breaches.

Energy and environmental impacts: Cold chains use 15 % de la consommation mondiale d’énergie. Yet breaches in integrity cause 25 % de nourriture de la chaîne du froid gaspillée, contributing significantly to greenhouse gas emissions. Studies show that fully refrigerated supply chains could cut food waste by 41 % globally—saving roughly 620 million metric tonnes of food and reducing emissions. An efficient bio vegetables cold chain supports sustainability and food security by preventing spoilage and reducing waste.

Understanding Temperature and Humidity Requirements for Bio Vegetables

Different vegetables require specific temperature and humidity conditions. Most refrigerated vegetables should stay between 0–5 °C (32–41 °F). Freezing is suitable for certain items at −18 °C to −23 °C to halt microbial activity and extend shelf life. Humidité élevée (90–95 %) prévient le flétrissement et la perte de poids. Delaying pre cooling after harvest allows respiration to continue and leads to texture damage. Apples and pears, Par exemple, must cool below 5 °C within 12–24 hours after harvest; otherwise their respiration remains high, reducing firmness and shelf life.

| Type de légume | Température recommandée | Plage d'humidité | Avantage pratique |

| Légumes-feuilles (laitue, épinard) | 0–5 °C | 90–95 % | Garde les feuilles croustillantes, prevents wilting and nutrient loss |

| Légumes racines (carottes, betteraves) | 0–4 °C | 90–95 % | Ralentit la respiration et la croissance microbienne, maintains texture |

| Légumes tropicaux (concombres) | 10–13 °C | 85–90 % | Prevents chilling injury; lower temperatures cause pitting and discoloration |

| Légumes surgelés (peas, mixed vegetables) | −18 °C ou moins | 0 % (congelé) | Stops microbial activity; preserves nutrients for months |

| Bio fruits (pommes, pears) | −0.5 °C ± 0.5 °C | 90–95 % | Rapid pre cooling prevents breakdown; delays reduce export quality |

Implication dans le monde réel: In a South African pome fruit facility study, researchers found that delays in pre cooling raised pulp temperatures above 5 °C, causing quality downgrading from export grade to local market. De la même manière, smallholder farmers in Africa who lacked access to forced air cooling lost up to 50 % of their harvest. Rapid cooling and controlled humidity can therefore translate directly into higher revenue and less waste.

Astuces et conseils pratiques pour réduire les pertes

Pré-refroidir rapidement: Remove field heat using forced air, vacuum or hydro cooling. Hydrocooling can be up to 15 times faster than air based methods, especially when combined with forced air systems.

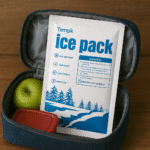

Utilisez un emballage approprié: Conteneurs en mousse isolés, vacuum sealed bags and gel packs stabilize temperature and protect against physical damage. Breathable films allow gas exchange while retaining moisture.

Surveiller l'humidité: Humidité équilibrée (85–95 %) empêche le flétrissement; sensors help maintain this range.

Installer des capteurs et des enregistreurs de données: IoT devices continuously track temperature and humidity and send alerts when deviations occur. Real time data enables immediate corrective actions, reducing losses.

Former le personnel: Educate workers on loading procedures, temperature requirements and emergency protocols to minimize human error.

Cas réel: A dairy cooperative equipped its refrigerated trucks with IoT sensors that detected a temperature spike when a door was left ajar. The system alerted staff, who closed the door, économie 500 litres of milk and preventing costly spoilage. This type of real time monitoring can benefit bio vegetable shipments as well.

Which Technologies Are Transforming the Bio Vegetables Cold Chain?

Technology enhances visibility, traceability and efficiency in the cold chain. Below are the key innovations shaping 2025.

Capteurs IoT et surveillance en temps réel

Continuous tracking: Les appareils IoT surveillent la température, humidité, location and shock events throughout transit. They provide alerts when thresholds are crossed, enabling operators to intervene quickly. Modern platforms integrate multiple networks (5G, LPWAN) to maintain connectivity and reduce latency. Automated logging eliminates manual errors and builds an audit trail for compliance.

Benefits for bio vegetables: For perishable vegetables, a single temperature excursion can trigger ice crystal formation or microbial growth. Real time data ensures immediate corrective action, préserver la qualité. Dans les régions en développement, mobile sensors combined with solar powered gateways allow remote farms to participate in cold chain networks.

Intelligence artificielle et optimisation des itinéraires

Routage intelligent: Machine learning algorithms analyse traffic, weather and demand to optimize delivery routes. Research demonstrates that clustering suppliers and predicting sales volume using Gaussian Process Regression reduced frozen goods logistics costs by 34.76 % et gaspiller par 15.6 %. Although the study focused on frozen goods, similar approaches apply to bio vegetables. By clustering farms and selecting optimal cross dock locations, AI minimizes travel time and energy consumption.

Maintenance prédictive: AI models forecast equipment failures in refrigeration units. Sensor data feed algorithms that recognise patterns of compressor wear or coolant leaks, allowing maintenance teams to fix issues before breakdowns cause spoilage.

Blockchain and Digital Ledger Technology

Traçabilité: Blockchain records every transaction and environmental data point in an immutable ledger. Lorsqu'il est combiné avec des capteurs IoT, the chain of custody becomes transparent—from farm to consumer. Regulators like the U.S. Loi sur la modernisation de la sécurité alimentaire (FSMA) Règle 204 require high risk foods to be traced within 24 heures; blockchain helps meet this standard by providing tamper resistant records.

Confiance des consommateurs: Transparent records allow consumers to verify that their bio vegetables were grown organically and maintained at proper temperatures. This trust commands premium pricing and fosters brand loyalty.

Digital Twins and Simulation Models

Virtual testing: Digital twins replicate the physical cold chain environment in software. They simulate what happens when there are delays, equipment failures or extreme weather. Using these models, managers can adjust scheduling, adjust set points and plan maintenance before real problems occur.

Conception durable: Digital twins also evaluate different packaging and refrigerant options for energy efficiency. Combiné avec l'IA, they suggest designs that reduce greenhouse gas emissions and operational costs.

Sustainable Refrigeration and Renewable Energy

Réfrigérants écologiques: Traditional refrigerants like HFCs have high global warming potential. Alternatives such as hydrofluoroolefins (HFO), CO₂ and ammonia deliver comparable performance with lower environmental impact. New packaging materials incorporate phase change materials that absorb heat and maintain temperature without heavy energy consumption.

Solar and wind integration: Dans les régions où le réseau électrique n’est pas fiable, off grid cold rooms powered by solar panels ensure constant refrigeration. Battery storage helps maintain temperature during cloudy periods or nighttime. Integrating renewable energy sources reduces operational costs and supports small farmers lacking reliable electricity.

How to Build an Integrated Bio Vegetables Supply Chain

A successful cold chain goes beyond equipment. It requires coordinated actions across the entire supply chain. Use this step by step approach to structure your operations.

Harvest and Pre Cool: Harvest vegetables during cooler parts of the day. Immediately remove field heat through forced air cooling, hydrocooling or vacuum cooling. Studies show that hydrocooling combined with forced air cooling can be 15 times faster than air cooling alone. Pulp temperatures should drop below 5 °C dans 24 hours for apples and pears.

Sanitize and Package: Laver, trim and package vegetables under controlled temperatures to prevent contamination. Use sanitized equipment to reduce pathogen load. Packaging should balance gas exchange and moisture retention to prevent wilting and condensation.

Entreposage frigorifique: Maintain warehouse temperatures at 0–4 °C for fresh vegetables and −18 °C for frozen stock. Separate storage zones by product type to prevent cross contamination and manage humidity.

Transport: Use refrigerated trucks or reefer containers with multi temperature compartments. Ensure continuous temperature monitoring via IoT sensors and GPS. Optimize route planning using AI to reduce travel time and fuel consumption.

Distribution et vente au détail: Keep multizone distribution centres with different temperature settings for various produce. At retail, rotate stock and avoid overcrowding, ensuring proper air circulation. Educate retailers on handling organic produce to maintain freshness.

Consumer Handling: Provide guidance on proper storage at home. Les États-Unis. Food and Drug Administration (FDA) advises that perishable items should not sit at room temperature for more than two hours—one hour if ambient temperatures exceed 32 °C (90 °F). Refrigerators should maintain temperatures at or below 4 °C (40 °F), and freezers at −18 °C (0 °F). Encourage consumers to refrigerate fresh bio vegetables promptly and consume them within a few days.

Integrated Cold Chain Best Practices

Slot booking and scheduling: To reduce congestion at collection points and packhouses, implement slot booking for inbound deliveries. This minimises waiting times, prevents temperature rise and ensures quick turnover.

Formation et SOP: Develop standard operating procedures for loading/unloading, palletizing and cleaning. Conducteurs de train, warehouse staff and retailers in cold chain protocols.

Collaboration with small farmers: Provide shared cold storage and transport services for smallholders to reduce costs and losses. Cooperative models can help farmers access modern infrastructure.

Amélioration continue: Use key performance indicators (KPI) such as spoilage rates, energy usage per kilogram, and on time deliveries. Review data regularly and iterate processes to improve efficiency.

Idée d'outil interactif

Cold Chain Health Scorecard: Create a self assessment tool where farmers and logistics managers rate their performance across six categories—pre cooling, conditionnement, stockage, transport, monitoring and training—on a 1–5 scale. The tool calculates a “cold chain health score,” highlights weak spots and recommends targeted improvements. Such interactive content increases user engagement and helps identify cost saving opportunities.

Cold Chain Bio Vegetables Supply Chain Trends and Forecasts for 2025

Market Growth and Consumer Demand

The global cold chain logistics market reached approximately USD 436.30 milliards en 2025 and is projected to soar to USD 1,359.78 milliards 2034 à un taux de croissance annuel composé (TCAC) de 13.46 %. The vegetables segment is growing as consumers seek fresh, minimally processed foods and plant based diets. Grand View Research estimates that the cold chain market (storage plus transportation) USD générés 316,339.6 millions en 2024 et pourrait atteindre USD 1,611,019.5 millions par 2033, reflétant un 20.1 % TCAC.

Regulatory and Transparency Drivers

Traceability requirements: Regulations like the FSMA Rule 204 aux États-Unis. mandate 24 hour traceability for high risk foods. Regions in Europe and Asia are implementing similar legislation. Digital traceability systems using blockchain will become standard.

Transparence du consommateur: Shoppers demand to know where and how their food is produced. Transparent supply chains build trust and support premium pricing for organic produce.

Sustainability and Social Impact

Food waste and loss contribute 8–10 % des émissions mondiales de gaz à effet de serre. En Afrique subsaharienne, smallholder farmers provide about 80 % de nourriture, mais à peu près 37 % of all food is lost before consumption. Fully refrigerated supply chains could reduce global food waste by 41 %, économiser sur 620 million metric tonnes of food. Sustainable practices such as using renewable energy, eco friendly refrigerants and reusable packaging will become not only ethical imperatives but also competitive advantages.

Geographic and Demographic Shifts

The Asia–Pacific region is forecast to experience the fastest growth in cold chain logistics, autour 14.3 % TCAC entre 2025 et 2034. Rising middle classes in China and India are consuming more exotic and organic vegetables, stimuler le commerce transfrontalier. Les alternatives à base de plantes pourraient représenter 7.7 % du marché mondial des protéines par 2030, further increasing demand for chilled vegetables. Urbanization and e commerce growth mean more consumers expect home delivery of fresh produce, pressuring retailers to optimize last mile cold chain systems.

Technological Innovations on the Horizon

Next generation sensors: Low power, self calibrating sensors that measure not only temperature and humidity but also ethylene levels and carbon dioxide will enhance quality control. Integration with 5G networks will allow high frequency data transmission without battery drain.

Autonomous refrigerated vehicles: Pilot programs are testing autonomous reefer trucks and drones for delivering small produce volumes to urban consumers. These vehicles reduce labour costs and increase delivery speed.

Réfrigération verte: Technologies using magnetic refrigeration or solid state cooling (thermoelectric or Peltier devices) sont émergents. Although still experimental, they promise energy savings and elimination of harmful refrigerants.

Digital marketplaces: Platforms connecting farmers, transporteurs, storage providers and retailers will streamline logistics, facilitate price transparency and match supply with demand more efficiently.

Composants et technologies clés pour la manipulation des légumes frais

To design an effective cold chain, you must master several technical elements.

Normes de température et pratiques de manipulation

Gamme réfrigération: Maintain 0–4 °C for most vegetables, as this slows microbial growth and maintains texture. Keep leafy greens and root vegetables at the lower end of the range, while tropical vegetables like cucumbers require slightly higher temperatures (10–13 °C) to avoid chilling injury.

Règle des deux heures: Les États-Unis. FDA recommends that perishable foods not sit at room temperature for more than two hours, ou une heure si les températures ambiantes dépassent 32 °C. Refrigerators should stay at or below 4 °C and freezers at −18 °C to prevent bacterial growth.

Rapid pre cooling: Remove field heat within 12–24 hours after harvest; delays lead to high respiration and quality decline. Use hydrocooling or vacuum cooling where possible, as hydrocooling is up to 15 times faster than air cooling.

Contrôle de l'humidité: Keep relative humidity at 90–95 % to prevent wilting. Too low humidity causes 3–10 % perte de poids, while too high humidity encourages mold.

Handling Methods and Equipment

Pre cooling equipment: Forced air coolers, hydrocoolers and vacuum coolers are essential for rapid cooling. Choosing the right method depends on crop type, packaging and investment capacity.

Stockage réfrigéré: Choose between mechanical refrigeration (compressor systems), absorption refrigeration or eco friendly alternatives like ammonia/CO₂ cascades. Evaluate energy efficiency and refrigerant environmental impact.

Véhicules de transport: Camions frigorifiques, railcars and containers should offer multi zone compartments and data logging. Pour les longues distances, insulated containers with phase change materials can maintain temperature without external power for several hours.

Common Questions About Bio Vegetables Cold Chains

Q1: What makes bio vegetables more sensitive to temperature than conventional vegetables?

Organic produce typically skips chemical preservatives, so it relies entirely on natural defence mechanisms. Sans refroidissement adéquat, enzymes break down nutrients and microbes multiply quickly, leading to faster spoilage. Cooling slows respiration and preserves vitamins.

Q2: Can I store all vegetables in the same refrigerated compartment?

Non. Some vegetables, such as cucumbers and eggplants, are sensitive to chilling injury and should be kept between 10–13 °C, while leafy greens and carrots thrive at 0–5 °C. Segregate produce by temperature needs and avoid mixing ethylene producing fruits (Par exemple, pommes) with ethylene sensitive vegetables.

Q3: How often should I check temperature during transport?

Use IoT sensors to continuously record temperature and humidity. Automated systems issue alerts when conditions deviate, allowing immediate action. Manual checks should still occur at loading, mid journey and unloading points to confirm sensor accuracy.

Q4: What affordable cold chain solutions are available for smallholder farmers?

Shared cold rooms powered by solar panels, insulated harvest boxes with ice packs and farmer cooperatives for pooled transport can make cold chains accessible. Lightweight data loggers connected via mobile networks provide affordable monitoring.

Q5: Does freezing damage vegetables?

Freezing halts microbial growth and preserves nutrients, mais cell walls rupture when ice crystals form. Blanch vegetables briefly before freezing to inactivate enzymes and prevent texture degradation. Always maintain −18 °C or below to keep frozen vegetables safe.

Q6: How long can bio vegetables stay at room temperature?

Suivez le règle des deux heures: perishable vegetables should not sit at room temperature for more than two hours, ou une heure si les températures ambiantes dépassent 32 °C. Beyond this period, bacteria multiply rapidly and food safety is compromised.

Suggestion

Principaux à retenir: A cost efficient cold chain bio vegetables supply chain requires rapid pre cooling, appropriate temperature and humidity control, robust packaging and real time monitoring. Maintaining temperatures between 0–5 °C and humidity around 90–95 % prevents spoilage and nutrient loss. Delays in cooling or temperature deviations lead to high respiration and quality downgrades. Technologies émergentes telles que les capteurs IoT, AI route optimisation and blockchain improve visibility and efficiency. Market trends show strong growth, increasing regulatory requirements and a shift towards sustainability. By integrating best practices from harvest to consumer and adopting innovative tools, producers can reduce waste, enhance profit and deliver high quality organic vegetables.

Plan d'action:

Évaluez votre chaîne du froid actuelle: Use the proposed self assessment scorecard to identify gaps in pre cooling, stockage, transport et surveillance.

Invest in rapid cooling equipment: Prioritise forced air and hydrocooling systems; ensure pulp temperatures fall below 5 °C dans 24 heures.

Mettre en œuvre la surveillance de l'IoT: Deploy sensors for continuous temperature and humidity tracking; set up real time alerts to prevent excursions.

Optimiser la logistique: Use AI driven route planning to minimize transit time and energy use; coordinate with partners via digital platforms.

Adopter des pratiques durables: Transition to eco friendly refrigerants and integrate renewable energy sources such as solar; use reusable containers.

Éduquer les parties prenantes: Train farmers, drivers and retailers on cold chain protocols; share consumer guidance on storage and the two hour rule.

À propos TempPK

TemPK is a leader in thermal packaging and cold chain solutions. Nous sommes spécialisés dans la conception réutilisable, boîtes isothermes écologiques, matériaux à changement de phase et packs de gel for food and pharmaceutical logistics. Notre R&D team continuously tests materials to achieve superior thermal performance while reducing environmental impact. Our solutions help organic farmers and distributors maintain optimal temperature and humidity control, enabling longer shelf life and lower spoilage. With robust quality assurance and certifications, TemPK products support regulatory compliance and consumer safety.

Appel à l'action: Ready to enhance your bio vegetables cold chain? Reach out to TemPK’s experts for tailored packaging solutions and technical guidance. We’re here to help you build a resilient supply chain that keeps your produce fresh, reduces waste and boosts profitability.