Comment optimiser votre stratégie de tarification des doublures de boîtes isothermes pour 2026?

Introduction

Understanding insulated box liner pricing is essential for businesses involved in cold chain logistics. Dans 2026, the pricing of insulated liners is influenced by multiple factors, including material choices, personnalisation, performance specifications, and freight costs. This comprehensive guide breaks down the pricing components and offers practical strategies to optimize your cold chain logistics while reducing costs.

In This Guide, We Will Answer:

What are the main factors that affect insulated box liner pricing in 2026?

How can you optimize your pricing strategy for bulk orders of insulated box liners?

What are the latest trends in insulated box liner pricing and how do they impact your operations?

How to calculate the true cost of insulated box liners per shipment?

What Determines Insulated Box Liner Pricing?

Insulated box liner pricing is not just about the unit price of the liner but includes several elements that influence the total cost. The biggest pricing factors are the materials used, performance d'isolation, and customization levels. En plus, shipping costs and supplier setup costs can also have a significant impact on the final price.

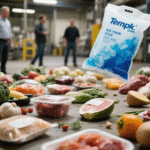

Sélection des matériaux

The material used for insulated box liners directly affects both performance and cost. Voici comment:

Foil and Bubble Liners: These are lightweight and cost-effective, suitable for short transit times where high insulation performance is not needed.

Polystyrène élargi (PSE): Common for medium-duration shipments, EPS provides a balance between affordability and thermal insulation.

Mousse de polyuréthane (PUF): Offers higher thermal resistance and is used for longer routes or shipments requiring higher insulation efficiency.

Panneaux isolés sous vide (VIP): Premium liners offering superior thermal resistance, often used for long-duration shipments or temperature-sensitive goods.

| Type de doublure | Matériel | Résistance thermique | Gamme de coûts | Meilleur cas d'utilisation |

|---|---|---|---|---|

| Déjouer & Bubble | Aluminium + Bubble Film | Modéré | Faible | Short-duration, local shipments |

| PSE | Polystyrène élargi | Modéré à élevé | Moyen | Expéditions standards, marchandises refroidies |

| Mousse de polyuréthane | Polyuréthane | Haut | Haut | Routes plus longues, marchandises surgelées |

| VIP | Panneau isolé de vide | Très haut | Très haut | Long-duration, produits sensibles |

Customization and Specifications

Customization is a key factor in pricing, as the more specific your needs, the higher the cost. Par exemple:

Custom Sizes: Tailored liners that perfectly fit your product’s dimensions increase manufacturing complexity and cost.

Special Features: Adding moisture resistance, marque personnalisée, or reinforced closures will raise the price.

How Freight and Packaging Costs Influence Pricing

While the unit cost of an insulated box liner is important, shipping and handling costs should also be factored into the total cost per shipment. Freight carriers often charge based on dimensional weight (FAIBLE), which is determined by the volume of the box, not just its physical weight.

Packaging Size: The larger the box, the higher the shipping cost. This can be mitigated by optimizing packaging dimensions and reducing unnecessary void space within the liner.

Méthode d'expédition: Air freight is faster but more expensive compared to ocean freight, which is slower but cheaper for bulk orders.

By choosing the right size and material, businesses can minimize DIM penalties and reduce shipping costs, ensuring cost-effective cold chain logistics.

Key Pricing Components Beyond the Unit Price

To gain a true understanding of insulated box liner costs, consider the following additional elements:

Coolant Costs: If your shipment requires coolant (Par exemple, des packs de gel ou de la neige carbonique), this will add to the overall cost per shipment.

Labor Costs: Packing time and the complexity of packaging also impact overall expenses. Efficient packing strategies can lower labor costs.

Failure Costs: Spoilage or product loss due to temperature excursions can lead to significant expenses. Investing in better-performing liners reduces these risks.

Logistique inversée: If you plan to reuse liners, factor in the costs of cleaning and maintaining the liners, especially for materials that can be recycled or reused.

How to Optimize Your Insulated Box Liner Pricing Strategy

1. Order in Bulk for Volume Discounts

One of the most effective ways to reduce the per-unit cost is to order in bulk. Many suppliers offer discounts for larger orders, which helps you save money on each liner. Cependant, ensure that your business has adequate storage space and cash flow to handle larger quantities without affecting other operations.

2. Standardize Liner Sizes

Using fewer standardized sizes across your shipments can help reduce costs by simplifying the manufacturing process and reducing the need for multiple liner types. Standardization leads to better economies of scale, reducing the overall cost per liner.

3. Negotiate with Suppliers

Suppliers often offer tiered pricing based on order volume. By negotiating with suppliers and committing to larger orders, you may be able to secure better pricing or favorable terms, such as extended payment deadlines or discounts on future purchases.

4. Match Insulation to Actual Needs

Avoid overspecifying insulation. Par exemple, if your products only require 24-hour protection, there’s no need to invest in high-performance materials designed for 72-hour or longer transit. Match your liner selection to the hold time and temperature requirements to avoid unnecessary costs.

5. Use Eco-Friendly Options to Save Long-Term

Sustainable packaging materials such as recyclable EPS or biodegradable paper-based liners can be more expensive initially but might lower your long-term disposal costs and align with environmental goals.

Latest Trends in Insulated Box Liner Pricing for 2026

Alors que nous entrons dans 2026, several trends are shaping the pricing landscape for insulated box liners:

1. Sustainability Drives Material Choices

Eco-friendly insulated box liners made from recyclable materials are becoming more common. These liners often come with a higher upfront cost but may reduce long-term disposal costs.

2. Smart Technology and Performance-Based Pricing

Smart packaging is on the rise, with temperature monitoring systems integrated into liners. While these liners come at a premium, they offer real-time tracking and can reduce product spoilage, ultimately saving costs.

3. Customization and Material Innovation

Customization is becoming increasingly popular as businesses seek to tailor liners to their exact product specifications. This trend is driving an increase in MOQ requirements and pricing, as suppliers invest in more specialized production methods.

Questions fréquemment posées (FAQ)

Q1: Why do insulated box liners vary in price?

The price of insulated box liners varies based on the material, performance requirements, and customization level. Premium liners with higher thermal resistance, like VIP, cost more than standard foil or bubble liners.

Q2: Can I negotiate the price of insulated box liners?

Oui, many suppliers are open to negotiation, especially for bulk orders or long-term partnerships. It’s always worth discussing pricing terms to secure better deals.

Q3: How can I lower the total cost of insulated box liners?

To reduce costs, consider ordering in bulk, optimizing packaging size, and selecting materials that match your specific needs without over-engineering the product. Negotiating better terms with suppliers also helps.

Conclusion: Maximizing Cost Efficiency in Insulated Box Liner Pricing

En conclusion, optimizing your insulated box liner pricing strategy in 2026 requires a comprehensive approach that considers material selection, volume de commande, and supplier negotiations. By aligning your purchasing strategy with your cold chain logistics needs and focusing on cost-effective solutions, you can achieve the best value while maintaining product quality.

Étape d'action: Contact a trusted supplier today to discuss your insulated box liner pricing needs and how to optimize your cold chain operations for maximum efficiency.

À propos du tempk

Tempk specializes in cold chain packaging solutions that focus on optimizing insulated box liner pricing. We help businesses reduce costs, improve logistics efficiency, and meet sustainability goals through customized solutions and supplier partnerships.

Entrer en contact: Contact us today for expert advice on how to optimize your insulated box liner pricing strategy and streamline your cold chain logistics.