1. Notes pour l'expédition de chocolat aux fraises

1. Contrôle de la température

Strawberry chocolate is very sensitive to temperature and should be kept in the range of 12-18°C to avoid melting or qualitative change caused by too high or too low temperature. Des températures excessives peuvent faire fondre le chocolat, affectant le goût et l'apparence, et endommager la texture et la saveur.

2. Humidity management

Keep a low humidity environment to prevent chocolate from moisture or dew, affectant le goût et l'apparence. Une humidité élevée provoquera un «glaçage» à la surface du chocolat, une couche de cristal blanche, ce qui affectera l'apparence du produit et le désir des consommateurs d'acheter.

3. Protection contre les chocs

Avoid violent vibration during transportation to prevent strawberry chocolate from breaking or deformation. La vibration peut non seulement détruire l'apparence du chocolat, mais peut également provoquer la séparation du matériau de remplissage intérieur (comme les fraises) du chocolat, affectant la texture et la structure globales.

4. Sécurité d'emballage

Use proper protective packaging to ensure that the chocolate is not squeezed and damaged during shipping. The strong packaging prevents damage to the chocolate caused by external pressure, but also provides additional insulation to help maintain the internal temperature.

2. Étapes d'emballage

1. Préparer les matériaux

-Moisture-proof film or plastic wrap: used to wrap in strawberry chocolate to prevent moisture intrusion.

-High efficiency incubator (e. g., PSE, PE, ou incubateur VIP): used to keep internal temperature stable.

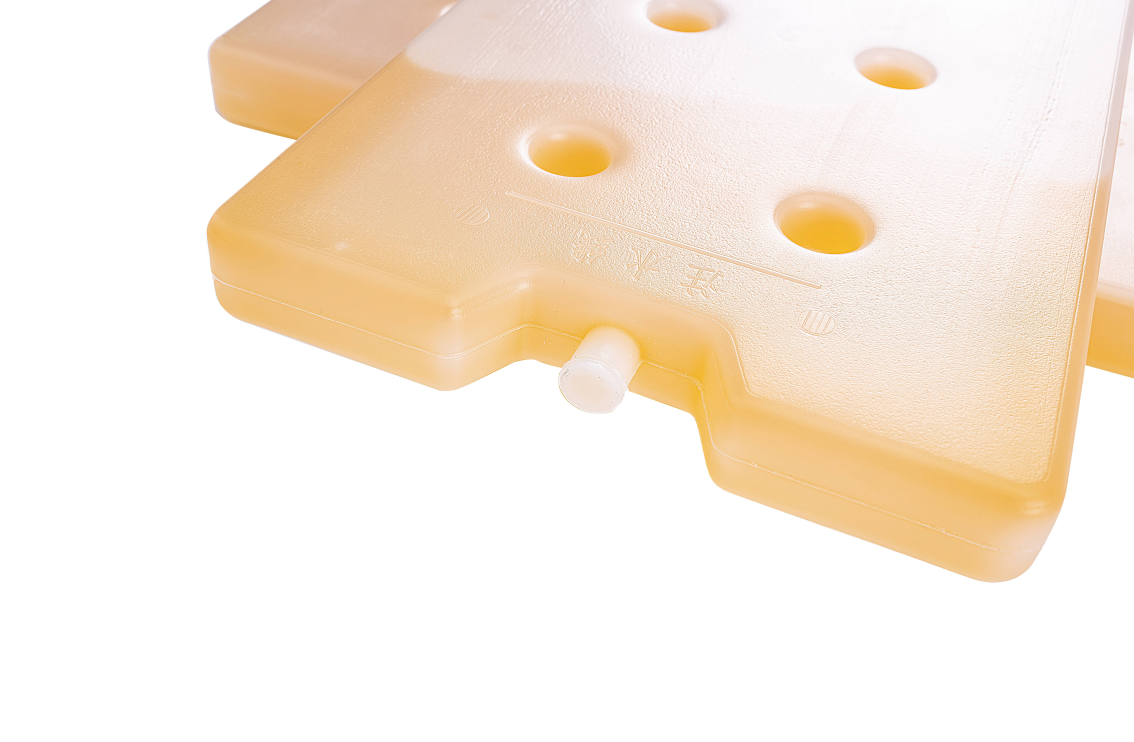

-Condensation (gel ice pack, glace technologique, or water injection ice pack): used to maintain a low temperature environment.

-Foam or bubble pad: used to fill voids to prevent movement and vibration during transport.

2. Pack the chocolate pack

Wrap strawberry chocolate in moisture or plastic wrap to ensure it is protected from moisture. The moisture-proof film prevents the icing on the chocolate surface and keeps it smooth and bright.

3. Into the incubator

Place the wrapped strawberry chocolate into an incubator, and place the refrigerant at the bottom and around the box to ensure that the temperature is evenly distributed. The refrigerant can choose gel ice bag, technology ice or water injection ice bag, according to the transportation distance and time for appropriate collocation.

4. Remplissez le vide

Use foam or bubble pads to prevent chocolate from moving and vibrating during transport. Foam and bubble pads can provide additional cushioning to absorb the impact force in transport and protect the chocolate from damage.

5. Sceller l'incubateur

Make sure the incubator is well sealed and labeled with “fragile items” and “refrigerated transportation” to remind logistics personnel to handle it carefully. A well-sealed incubator can effectively maintain the internal temperature and prevent cold air leakage.

3. Méthode de contrôle de la température

1. Choisissez le matériau d'isolation thermique approprié

Utiliser l'EPS, PPE ou incubateur VIP, these materials have good thermal insulation performance and can effectively prevent the influence of external temperature on the temperature in the incubator. EPS incubator is suitable for short-distance transportation, EPP incubator is suitable for medium and long-distance transportation, while VIP incubator is suitable for long-distance and high-value products.

2. Utilisez le milieu réfrigérant approprié

Place a sufficient amount of refrigerant (comme les packs de glace en gel, technology ice or water ice packs) at the bottom and around the incubator to ensure a low temperature environment throughout transportation. Adjust the quantity and distribution position of refrigerant according to the transportation time and ambient temperature to achieve the best insulation effect.

3. Surveillance de la température en temps réel

Place the temperature monitoring equipment in the incubator to monitor the temperature change in the incubator in real time to ensure that the temperature is always maintained between 12-18°C. En cas de température anormale, take timely measures to adjust the position of the ice packs or increase the number of ice packs. The temperature monitoring device can be viewed in real time through a mobile phone or computer to ensure temperature transparency and security during transportation.

4. Professional solutions for Huizhou Industry

Maintaining the temperature and texture of strawberry chocolate is crucial. Strawberry chocolate needs to be transported at the right temperature to prevent melting or deterioration. Huizhou Industrial Cold Chain Technology Co., Ltée. Fournit une série de produits de transport de chaîne froide efficaces, Ce qui suit est notre proposition professionnelle.

1.Produits Huizhou et scénarios applicables

1.1 Pack de glace en eau

-Température d'application principale: 0℃

-Scénario applicable: For products that need to be kept around 0℃, such as some strawberry chocolate that needs to be kept low but does not freeze.

1.2 Sac à glace à l'eau saline

-Plage de températures d'application principale: -30℃ à 0 ℃

-Scénario applicable: Suitable for strawberry chocolate that requires lower temperatures to ensure that it does not melt during transportation.

1.3 Pack de glace en gel

-Plage de températures d'application principale: 0℃ à 15 ℃

-Scénario applicable: For strawberry chocolate at slightly low temperatures to ensure the appropriate temperature during transportation.

1.4 Matériaux de changement de phase organique

-Plage de températures d'application principale: -20℃ à 20 ℃

-Scénario applicable: Suitable for accurate temperature-controlled transportation in different temperature ranges, such as strawberry chocolate maintained at room temperature or refrigerated.

1.5 Glacière planche à glace

-Plage de températures d'application principale: -30℃ à 0 ℃

-Scénario applicable: Strawberry chocolate for short trips and for low temperatures.

2.L'isolation peut

2.1Incubateur VIP

-Caractéristiques: Utilisez la technologie des plaques d'isolation sous vide pour fournir le meilleur effet d'isolation.

-Scénario applicable: Suitable for the transportation of high-value strawberry chocolate, Assurer la stabilité à des températures extrêmes.

2.2Incubateur EPS

-Caractéristiques: Matériaux en polystyrène, faible coût, Convient aux besoins généraux d'isolation thermique et au transport à courte distance.

-Scénario applicable: For strawberry chocolate transportation that requires moderate insulation effect.

2.3 Incubateur EPP

-Caractéristiques: matériau en mousse à haute densité, Fournir de bonnes performances d'isolation et de durabilité.

-Scénario applicable: Suitable for strawberry chocolate transportation requiring long insulation time.

2.4Incubateur PU

-Caractéristiques: matériau en polyuréthane, Excellent effet d'isolation thermique, Convient pour le transport à longue distance et les exigences élevées de l'environnement d'isolation thermique.

-Scénario applicable: suitable for long-distance and high-value strawberry chocolate transportation.

3.1 Sac d'isolation en tissu Oxford

-Caractéristiques: léger et durable, Convient pour le transport à courte distance.

-Scénario applicable: suitable for the transportation of small batch of strawberry chocolate, facile à transporter.

3.2 Sac d'isolation thermique non tissé

-Caractéristiques: Matériaux respectueux de l'environnement, bonne perméabilité aérienne.

-Scénario applicable: Convient pour le transport de courte distance pour les exigences d'isolation générale.

3.3 Sac d'isolation en aluminium

-Caractéristiques: chaleur réfléchie, bon effet d'isolation thermique.

-Scénario applicable: suitable for medium and short distance transportation and moisturizing strawberry chocolate.

4. Recommended plan according to the strawberry chocolate transportation requirements

4.1 Long Distance Strawberry Chocolate Shipping

-Solution recommandée: Use a saline ice pack or ice box ice with a VIP incubator to ensure that the temperature remains at 0℃ to 5℃ to maintain the texture and texture of strawberry chocolate.

4.2 Short-haul strawberry for chocolate shipping

-Solution recommandée: Use gel ice packs with a PU incubator or EPS incubator to maintain a temperature between 0℃ and 15℃ to prevent strawberry chocolate from melting during transportation.

4.3 Midway strawberry for chocolate shipping

-Solution recommandée: Use organic phase change materials with an EPP incubator to ensure that the temperature is maintained within the appropriate range and maintain the freshness and quality of strawberry chocolate.

En utilisant les produits de stockage et d'isolation à froid de Huizhou, you can ensure that strawberry chocolate maintains the best temperature and quality during transportation. We are committed to providing our customers with the most professional and efficient cold chain transportation solutions to meet the transportation needs of different types of strawberry chocolate.

5. Service de surveillance de la température

Si vous souhaitez obtenir les informations de température de votre produit pendant le transport en temps réel, Huizhou vous fournira un service professionnel de surveillance de la température, Mais cela entraînera le coût correspondant.

6. Notre engagement envers le développement durable

1. Matériaux respectueux de l'environnement

Notre entreprise s'est engagée dans la durabilité et utilise des matériaux respectueux de l'environnement dans des solutions d'emballage:

-Conteneurs d'isolation recyclables: Nos conteneurs EPS et EPP sont faits de matériaux recyclables pour réduire l'impact environnemental.

-Réfrigérant biodégradable et milieu thermique: Nous fournissons des sacs de glace en gel biodégradables et des matériaux de changement de phase, sûr et respectueux de l'environnement, Pour réduire les déchets.

2. Solutions réutilisables

Nous faisons la promotion de l'utilisation de solutions d'emballage réutilisables pour réduire les déchets et réduire les coûts:

-Conteneurs d'isolation réutilisables: Nos conteneurs EPP et VIP sont conçus pour une utilisation multiple, Fournir des économies de coûts à long terme et des avantages environnementaux.

-Réfrigérant réutilisable: Nos packs de glace en gel et nos matériaux à changement de phase peuvent être utilisés plusieurs fois, Réduire le besoin de matériaux jetables.

3. Pratique durable

Nous adhérons à des pratiques durables dans nos opérations:

-Efficacité énergétique: Nous mettons en œuvre des pratiques d'efficacité énergétique pendant les processus de fabrication pour réduire l'empreinte carbone.

-Réduire les déchets: Nous nous efforçons de minimiser les déchets grâce à des processus de production efficaces et à des programmes de recyclage.

-Initiative verte: Nous sommes activement impliqués dans des initiatives vertes et soutenons les efforts de protection de l'environnement.