Comment utiliser des packs de glace sec pour l'expédition de médicaments: Meilleures pratiques & Conformité

Shipping temperature-sensitive medicines requires the highest standards of care. Les packs de glace sec sont une partie essentielle de la logistique médicale, Assurer la sécurité, conforme, et expédition efficace. Ce guide explique les meilleures pratiques pour utiliser des packs de glace sèche, Assurer la conformité aux réglementations, et maximiser le contrôle de la température pendant l'expédition de médicaments sensibles.

-

Comment calculer les exigences de glace sèche pour l'expédition de médicaments?

-

Quelles sont les exigences d'emballage pour la glace sèche dans les expéditions médicales?

-

Comment assurez-vous la conformité aux réglementations de transport pour l'expédition de médicaments avec de la glace sèche?

-

Quelles sont les principales considérations de sécurité pour la manipulation de la glace sèche pendant l'expédition?

-

Comment les sacs à glace sec pour la médecine assurent-ils un transport sûr?

What are Dry Ice Packs for Medicine and Why Are They Essential in Medical Logistics?

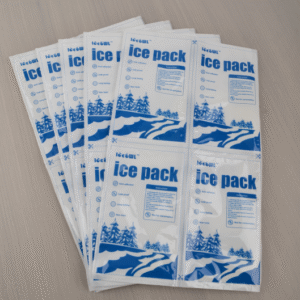

Les packs de glace sec sont un dioxyde de carbone solidifié (Co₂), Largement utilisé dans la logistique de la chaîne froide pour maintenir des températures ultra-bas pour les médicaments sensibles à la température comme les vaccins, biologique, et produits pharmaceutiques. Contrairement à la glace traditionnelle, La glace sèche sublime directement du solide au gaz, leaving no liquid water, which makes it perfect for preserving product integrity during transit.

Avantages clés:

-

Precise Temperature Control: Maintains freezing temperatures (as low as -78°C) throughout shipment.

-

No Residual Water: Prevents moisture from damaging medical packaging.

-

Effective for Long-Distance Shipping: Ideal for both domestic and international shipments, ensuring timely delivery without temperature excursions.

How to Calculate Dry Ice Requirements for Medicine Shipments?

To prevent the degradation or spoilage of medicines during transit, calculating the right amount of dry ice is crucial.

Rule of Thumb for Dry Ice Calculation:

-

24-hour shipment: 5–10 lb of dry ice per 24 hours for well-insulated packages.

-

48-72 hour shipment: 10-20 lb of dry ice per 24 hours depending on packaging and environmental factors.

Practical Example:

A shipment of insulin requiring a 4°C range for 48 hours may need approximately 10 lb of dry ice. For a 72-hour shipment, the dry ice requirement might increase to 15 lb depending on conditions.

| Shipping Time | Dry Ice Requirement | Type d'emballage | Notes |

|---|---|---|---|

| 24 heures | 5–10 lb | Well-insulated EPS | Short routes, minimal thaw risk |

| 48 heures | 10–15 lb | Standard EPS/VIP | Moderate to long-distance |

| 72 heures | 15–20 lb | VIP or double-insulated | Longer durations, high heat risk |

What Are the Packaging Requirements for Dry Ice in Medical Shipments?

Dry ice packaging must meet safety regulations and ensure the integrity of the shipped products.

Key Packaging Considerations:

-

Vented containers: Essential to prevent pressure buildup as dry ice sublimates.

-

Étiquetage approprié: All shipments must be labeled with UN1845 et “Dioxyde de carbone, solide” to comply with international shipping regulations.

-

Sealing and insulation: Use airtight packaging with proper venting. Vapor-barrier bags can help prevent moisture buildup.

-

Pre-chilling products: Ensure medicines are properly chilled or frozen before packing to minimize energy loss.

-

Data loggers: Track temperatures during shipment to ensure compliance with required temperature ranges.

How to Ensure Compliance with Transportation Regulations?

Regulatory compliance is critical in medical shipments involving dry ice. Key guidelines come from the IATA Dangerous Goods Regulations (DGR) et NOUS. DOT regulations.

Key Regulations:

-

IATA DGR: Requires labeling with UN1845, Classe 9, and net weight in kilograms for international air shipments.

-

NOUS. POINT: Limits dry ice weight per package to ≤200 kg.

-

Venting requirement: Ensure containers are vented to allow CO₂ gas to escape.

What Are the Key Safety Considerations for Handling Dry Ice During Shipment?

Dry ice’s extreme cold temperature and sublimation into CO₂ gas require specific handling precautions.

Safety Guidelines:

-

Portez des gants isolés Pour éviter les engelures.

-

Assurer la ventilation to avoid carbon dioxide accumulation, which could lead to asphyxiation.

-

Évitez les conteneurs scellés to prevent pressure buildup during sublimation.

Étude de cas: A pharmaceutical company faced shipment delays due to improper dry ice handling, where a non-vented package ruptured, causing product loss. Following this incident, they standardized handling procedures to ensure safe shipment practices.

2025 Updates and Trends for Dry Ice in Medical Shipping

The cold chain industry for medical logistics is rapidly evolving. À ce jour 2025, new technologies and materials are shaping the way dry ice is used in pharmaceutical shipments.

Tendances clés:

-

Digital Cold Chain Monitoring: Real-time temperature tracking via IoT sensors is becoming standard in medical shipments.

-

Better Insulation Materials: Advances in insulation technologies are reducing dry ice requirements and extending shipment durations.

-

Eco-friendly Packaging: There is increasing adoption of reusable and recyclable packaging solutions to reduce the carbon footprint.

Questions fréquemment posées

Q: How long does dry ice last during shipment?

Dry ice typically lasts 24–72 hours depending on the amount used and the insulation quality. Pour les expéditions plus longues, more dry ice or specialized packaging is required.

Q: What regulations apply when shipping medicine with dry ice?

Regulations include proper labeling (UN1845), limites de poids, and the requirement for vented containers to release CO₂ gas. Always comply with the FDA et Iata lignes directrices.

Q: How do I dispose of leftover dry ice after delivery?

Allow dry ice to sublimate (turn to gas) in a well-ventilated area. Never seal dry ice in an airtight container.

Résumé & Recommandations

Dry ice packs are vital in ensuring the safe and effective shipment of temperature-sensitive medicines. They provide reliable cooling, prevent product degradation, and ensure compliance with international shipping regulations.

Étapes d'action:

-

Calculate dry ice requirements based on shipment duration and packaging type.

-

Ensure proper labeling and vented packaging to comply with regulations.

-

Use data loggers to monitor temperatures throughout the shipment.

À propos du tempk

Tempk specializes in temperature-controlled packaging solutions for the pharmaceutical and medical industries. Our dry ice packs offer consistent, reliable cooling for safe, conforme, and timely medical shipments. Contact us for customized cold chain solutions.