Why Perishables Need Ice Box Coolers

Imaginez ça: Un camion plein de fruits de mer frais quitte le quai. Au moment où il atteint un magasin 8 heures plus tard, Le poisson est gâté. Ou une expédition de vaccins se trouve dans un entrepôt chaud - maintenant inutile pour les patients. Ces catastrophes se produisent quotidiennement, Mais ils sont évitables. Entrerice box coolers: les héros méconnus de la logistique de la chaîne du froid. Ces conteneurs isolés sont conçus pour se verrouiller dans le froid, Protéger les denrées périssantes, et protéger les marchandises des pointes de température ou des creux. Dans ce guide, Nous expliquerons pourquoi les refroidisseurs de boîtes à glace comptent, Comment ils fonctionnent, Et pourquoi les boîtes à glace de Tempk sont le meilleur choix pour vos besoins en chaîne froide.

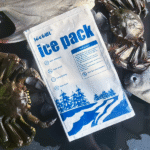

Qu'est-ce qu'un refroidisseur de boîte à glace?

Unglacièreest un portable, conteneur isolé construit pour maintenir une température froide régulière pendant le transport. Considérez-le comme un «réfrigérateur mobile» pour les périssables - mais la manière plus solide. La plupart des boîtes à glace utilisent un mélange d'isolation (comme des couches épaisses en mousse ou sous vide) et agents de refroidissement (glace, packs de gel, ou glace sèche) to keep items cold for hours or even days.

They’re made from tough materials like high-density polyethylene (HDPE) ou polypropylène, which resist punctures, crushing, et humidité. This means your products stay protected, even if the cooler takes a bump during shipping.

Why Ice Box Coolers Are a Cold Chain Must-Have

1. Stop Temperature Swings in Their Tracks

Perishables like berries, vaccins, and blood plasma are picky—they thrive in narrow temperature ranges (Par exemple, 0–4 ° C pour les produits laitiers, -20° C pour les vaccins). Ice box coolers act as a “thermal shield,” slowing heat transfer from outside. This keeps items within their safe zone, preventing spoilage or reduced potency.

2. Extend Shelf Life, Save Money

When products stay cold, they last longer. Pour les restaurants, that means less wasted food. For drug companies, it means more usable vaccines. Ice boxes reduce the need for expensive refrigerated trucks, making them a budget-friendly solution for small businesses or long-haul deliveries.

3. Tough Enough for Rough Rides

Cold chain logistics isn’t gentle—boxes get stacked, dropped, or left in hot parking lots. Ice box coolers are built to handle it. Their rigid shells and reinforced lids protect contents from impacts, while the insulation keeps cooling consistent, no matter the handling.

4. Écologique & Rentable

Most ice boxes are reusable (no single-use ice packs needed!), réduire les déchets. Au fil du temps, this saves money—no more buying disposable gel packs—and aligns with consumer demand for sustainable practices.

5. Fit Any Cold Chain Scenario

Need to chill a lunchbox? There’s a small ice box for that. Shipping a pallet of frozen meat? Try a large, stackable model. Ice boxes come in all sizes, making them versatile for restaurants, pharmacies, commerce électronique, Et plus.

Where Ice Box Coolers Shine: Top Applications

- Livraison de nourriture: From farm-to-table salads to overnight sushi, ice boxes keep ingredients fresh and safe.

- Expédition de produits pharmaceutiques: Vaccins, insuline, and biologics rely on ice boxes to maintain life-saving temperatures.

- Medical Samples: Sang, tissu, and lab specimens need strict cooling—ice boxes deliver.

- Épicerie de commerce électronique: Online shoppers expect frozen pizza and ice cream to arrive intact. Ice boxes make it happen.

- Restauration & Événements: Buffet trays, desserts, and cold drinks stay chilled from kitchen to venue.

Why Tempk’s Ice Boxes Outperform the Rest

Pendant que les glacières génériques fonctionnent, Tempk’s are engineered for modern cold chain challenges. Voici ce qui les distingue:

1. Isolation de qualité militaire

Tempk utilise un système d'isolation à double couche: un noyau en mousse dense et une couche extérieure réfléchissante. Ce combo bloque mieux la chaleur que les refroidisseurs standards, keeping contents cold for 2x longer (même à 35°C de chaleur!).

2. Built Like a Tank

À partir de 100% PEHD de qualité alimentaire, Tempk ice boxes are puncture-resistant, UV-stabilized, and crack-proof. They’ve survived drop tests from 3 feet and crushing weights of 500 lbs—so your products stay safe.

3. Personnalisable pour vos besoins

Need a cooler that fits your logo? Tempk offers custom printing. Want a specific size for pallets or small parcels? They’ve got you covered. Choisissez parmi 10+ tailles, from “lunchbox tiny” to “pallet-sized extra-large.”

4. Anti-fuite & Coffre-fort

Tempk’s tight-seal lids prevent spills (no more soggy salads!). The gel packs inside are non-toxic and FDA-approved, making them safe for food, médicaments, et produits pour bébé.

5. Eco-conscient par conception

Tempk ice boxes are 100% reusable—just clean and refill. Their recycled plastic construction reduces waste, and they’re easy to repair if scratched or dented.

Conclusion

Les glacières sont l’épine dorsale de la logistique de la chaîne du froid, protecting perishables and keeping businesses running smoothly. Tempk’s ice boxes take reliability to the next level, with superior insulation, durabilité, et personnalisation. Whether you’re shipping sushi across town or vaccines across continents, Tempk’s coolers ensure your products arrive fresh, sûr, et prêt à l'emploi.

Upgrade your cold chain today—because when perishables thrive, votre entreprise prospère.