Dans 2025, packs de glace carbonique logistique have become an essential component in the cold chain logistics industry, ensuring the safe and effective transport of temperature-sensitive goods such as pharmaceuticals, produits biotechnologiques, et les aliments périssables. Glace sèche, with its ability to maintain ultra-low temperatures without leaving moisture residue, is an indispensable tool for preventing spoilage and ensuring product quality. This guide delves into how logistics dry ice packs work, leurs avantages, meilleures pratiques, and how innovations are reshaping their use in the cold chain.

What Are Logistics Dry Ice Packs and Why Are They Essential?

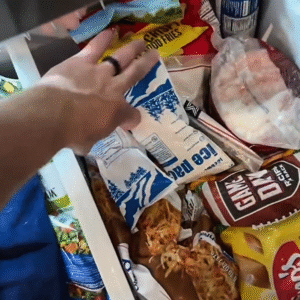

Logistics dry ice packs consist of solidified carbon dioxide (Co₂), which sublimate directly from solid to gas at -78.5°C (-109.3°F). This ability to transition without melting into liquid makes dry ice ideal for maintaining a sub-zero environment during shipping, without the risk of water damage to goods. The effectiveness of dry ice makes it particularly valuable for industries requiring precise temperature control, comme les produits pharmaceutiques, biotechnologie, et logistique alimentaire.

Key Benefits of Using Dry Ice Packs:

-

Températures ultra-basses: Dry ice ensures goods are kept at optimal temperatures, especially important for vaccines, insuline, et des échantillons biologiques.

-

Pas de résidu: Alors que la neige carbonique se sublime en gaz, it eliminates the risk of water damage, unlike traditional ice which leaves liquid behind.

-

Durée de refroidissement plus longue: With appropriate packaging, dry ice can maintain freezing conditions for up to 48 heures ou plus, making it an ideal solution for long-distance shipments.

Meilleures pratiques d'utilisation de la glace carbonique dans la logistique de la chaîne du froid

1. Emballage approprié

To optimize the cooling effect of dry ice, it’s essential to use insulated packaging. The packaging should be designed to slow the sublimation rate of dry ice, ensuring prolonged cooling during transit. Consider using sturdy containers that can withstand the physical demands of shipping while providing excellent insulation.

2. Ventilation adéquate

Alors que la neige carbonique se sublime en gaz CO₂, it’s crucial to ensure proper ventilation. Sealing containers airtight can cause CO₂ gas buildup, leading to safety concerns. Proper ventilation allows the gas to escape safely, reducing risks associated with CO₂ accumulation in confined spaces.

3. Étiquetage correct

Dry ice shipments must be properly labeled according to transportation regulations, such as the UN1845 standard. The label must include hazard warnings and necessary handling instructions to ensure safe handling during transport.

Applications of Dry Ice in Cold Chain Logistics

1. Pharmaceutiques et biologiques

Dry ice is critical for the transport of temperature-sensitive pharmaceutical products, y compris les vaccins et les produits biologiques, qui nécessitent des températures inférieures à zéro. By maintaining optimal conditions, dry ice helps prevent degradation and ensures the efficacy of these sensitive items.

2. Aliments périssables

Pour la logistique alimentaire, dry ice is invaluable when shipping frozen goods like seafood, viande, et glace. It keeps products frozen for extended periods, Empêcher la décongélation et la détérioration, which is especially important for long-distance and international shipments.

3. Échantillons biologiques

Transport d'échantillons biologiques, such as lab specimens, requires strict temperature control. Dry ice is ideal for these applications, as it keeps biological materials frozen and safe from temperature fluctuations, ensuring sample integrity throughout transport.

Considérations de sécurité lors de la manipulation de glace sèche

1. Utiliser un équipement de protection

Portez toujours des gants isolés lors de la manipulation de la glace sèche pour éviter les engelures. Dry ice can cause severe skin burns upon direct contact, so protective gear is essential for safe handling.

2. Évitez les espaces confinés

Never store or use dry ice in confined spaces without proper ventilation. CO₂ gas can accumulate in poorly ventilated areas, entraînant des risques d’asphyxie. Always ensure that areas are well-ventilated to allow for the safe dissipation of CO₂ gas.

3. Disposition appropriée

La glace carbonique doit pouvoir se sublimer dans un endroit bien ventilé. Avoid disposing of dry ice in sinks or trash bins, as this can cause an unsafe build-up of gas. Let the dry ice evaporate naturally in an open space.

Innovations in Dry Ice Technology for 2025

À mesure que l'industrie de la chaîne du froid évolue, innovations in dry ice technology are enhancing shipping efficiency and sustainability. Notable advancements include:

-

Biodegradable Insulation Materials: Companies are now using biodegradable materials for insulation, which help reduce environmental impact while maintaining effective temperature control.

-

Smart Temperature Monitoring Systems: IoT-enabled sensors provide real-time temperature monitoring, ensuring that shipments remain within the required temperature range throughout the entire transport process.

-

Reusable Dry Ice Containers: Reusable containers made from durable materials are becoming more common, allowing companies to reduce waste while maintaining the performance of their cold chain solutions.

These advancements, coupled with a growing emphasis on sustainability, are reshaping the future of cold chain logistics. The demand for eco-friendly packaging, better temperature control, and cost-efficient solutions continues to rise, making dry ice packs an even more integral part of the logistics process.

Conclusion: How to Optimize Your Cold Chain Logistics with Dry Ice

Dans 2025, logistics dry ice packs continue to be a cornerstone of cold chain shipping, ensuring that temperature-sensitive goods are transported safely, efficacement, and without compromise. By following best practices for dry ice usage, leveraging the latest technological advancements, and maintaining a focus on sustainability, les entreprises peuvent optimiser leurs opérations de chaîne du froid. Dry ice’s extended cooling durations and moisture-free properties make it an ideal solution for a wide range of industries, y compris les produits pharmaceutiques, nourriture, et biotechnologie.

Étapes suivantes: Enhance Your Cold Chain with Dry Ice Solutions

Take the next step in optimizing your cold chain logistics by incorporating dry ice packs into your shipping strategy. Evaluate your current shipping requirements, assess the duration and temperature needs of your products, and consult with a logistics provider for tailored dry ice solutions that will ensure the safety and integrity of your goods.

À propos du tempk

Tempk est spécialisé dans la fourniture de solutions de chaîne du froid de haute qualité, including logistics dry ice packs, emballage à température contrôlée, and smart shipping kits. Avec un engagement envers la qualité et la durabilité, Tempk ensures your products remain safe and compliant during every phase of the shipping process.

For more information on how our solutions can improve your cold chain logistics, contactez Tempk aujourd'hui.