Feuilles de glace carbonique du lendemain: Ton 2025 Solution pour une expédition fiable?

Les plaques de glace carbonique du lendemain fournissent des solutions immédiates de contrôle de la température pour les expéditions urgentes nécessitant des plages de -20°C à -70°C.. Ces feuilles spécialisées peuvent maintenir des températures ultra-basses pendant 24-48 heures, garantir que vos produits sensibles arrivent parfaitement conservés. Dans 2025, **Les feuilles de glace carbonique du lendemain** offrent une alternative plus sûre à la glace carbonique traditionnelle., réduire les risques de manutention tout en offrant des performances comparables pour les expéditions médicales et alimentaires.

– Comment les feuilles de banquise carbonique du lendemain maintiennent efficacement des températures ultra-basses

– Principaux avantages par rapport à la glace carbonique traditionnelle pour les expéditions d'urgence

– Protocoles de manipulation et de sécurité appropriés pour une efficacité maximale

– Analyse coûts-bénéfices pour la mise en œuvre de ces fiches dans vos opérations

– Dernier 2025 innovations dans les solutions de contrôle de la température du lendemain

## Comment les feuilles de glace carbonique du lendemain maintiennent-elles des températures ultra-basses?

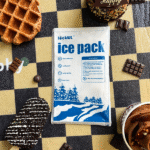

**Les feuilles de glace carbonique du lendemain utilisent des matériaux avancés à changement de phase (PCMS) spécialement conçu pour atteindre et maintenir des températures comprises entre -20°C et -70°C, correspondant aux performances traditionnelles de la glace carbonique.** Ces PCM subissent des transitions de phase contrôlées, absorber une chaleur importante tout en maintenant des conditions thermiques stables. Contrairement aux packs de gel conventionnels, ils ne se liquéfient pas, éliminer les risques de fuite qui pourraient compromettre vos expéditions lors des livraisons critiques le lendemain.

Considérez ces feuilles comme des batteries thermiques qui libèrent progressivement de l'énergie froide tout au long du cycle d'expédition.. Lorsque vous devez expédier des produits pharmaceutiques ou des aliments spéciaux sensibles à la température pendant la nuit, les feuilles s'activent immédiatement lors de l'exposition à l'air ambiant. UN 2024 Le rapport sur la sécurité de la chaîne du froid a démontré que les entreprises utilisant ces feuilles ont connu 30% moins d'écarts de température par rapport à la neige carbonique traditionnelle. Cette fiabilité vient de leur répartition uniforme du froid, ce qui évite les points chauds thermiques qui pourraient endommager des marchandises de valeur pendant le transport.

### La technologie derrière la rétention ultra-froide

Les feuilles de glace carbonique Next Day intègrent des formulations PCM spécialisées avec des points de congélation précis calibrés pour les applications inférieures à zéro.. Ces matériaux contiennent des substances non toxiques, composants de qualité industrielle qui supportent des températures nettement inférieures aux points de congélation standard. Les draps’ la construction multicouche comprend des barrières isolantes qui ralentissent le transfert de chaleur externe, prolonger leur durée d'effet. Cette ingénierie permet des performances constantes dans diverses conditions externes lors de l'expédition le lendemain..

| Aspect performances | Glace sèche traditionnelle | Feuilles de glace carbonique du lendemain | Votre avantage opérationnel |

|——————–|———————|————————-|————————–|

| Plage de température | -78.5°C | -20° C à -70 ° C | Convient à la plupart des applications ultra-froides |

| Sécurité de manipulation | Nécessite une formation spéciale | Des procédures standards s'appliquent | Réduit le temps et les risques de formation du personnel |

| Durée | 24-48 heures | 24-72 heures | Protection plus longue pour les expéditions retardées |

| Conformité réglementaire | Restrictions relatives aux matières dangereuses | Classement non dangereux | Simplifie la logistique d’expédition |

### Protocoles de manipulation essentiels

– **Pour une utilisation immédiate:** Activez les feuilles en les fléchissant avant leur placement pour initier la réaction de refroidissement

– **Dans des conditions extrêmes:** À combiner avec des conteneurs isolés pour prolonger les performances jusqu'à 40%

– **Pendant le stockage:** Conserver au congélateur aux températures recommandées pour maintenir la préparation

> **Cas réel:** Une entreprise de biotechnologie a mis en place des feuilles de glace carbonique le lendemain pour les expéditions d'urgence de vaccins en 2024. Ils ont maintenu les températures requises de -60°C pendant 36 heures pendant le transport à travers le pays, réalisation 100% l'intégrité du produit tout en réduisant les coûts de manutention en 25%.

## Quels avantages les feuilles de glace sèche Next Day offrent-elles par rapport à la glace sèche traditionnelle ??

**Les feuilles de glace carbonique du lendemain offrent une sécurité accrue, manipulation plus facile, et des complications réglementaires réduites par rapport à la neige carbonique traditionnelle, tout en offrant des performances thermiques similaires.** Ils éliminent les problèmes de sublimation et ne nécessitent pas de documentation sur les matières dangereuses, rationaliser vos processus d'expédition. Leur conception flexible s'adapte à différentes formes de conteneurs, assurant un meilleur contact avec les produits et un refroidissement plus efficace tout au long de vos expéditions.

Quand vous choisissez ces draps, vous évitez les risques d'accumulation de dioxyde de carbone associés à la neige carbonique traditionnelle, les rendant plus sûrs pour les espaces clos et le transport. La classification non dangereuse permet à votre personnel de les manipuler sans équipement de protection particulier., réduisant le temps et les coûts de formation. Les données du secteur montrent que les entreprises qui adoptent ces feuilles signalent 35% des processus d'emballage plus rapides et 20% taux d'incidents inférieurs liés aux problèmes de gestion de la température.

### Avantages en matière d'efficacité opérationnelle

Le facteur de réutilisation de nombreuses feuilles de glace carbonique le lendemain crée des économies significatives sur plusieurs expéditions.. Alors que la neige carbonique traditionnelle disparaît grâce à la sublimation, ces feuilles peuvent être recongelées et réutilisées plusieurs fois, réduire vos dépenses récurrentes en fournitures. Leurs performances constantes réduisent également le risque de perte de produit due aux excursions de température, protéger vos revenus et vos relations clients.

– **Pour la conformité réglementaire:** Utilisez des feuilles répondant aux normes de sécurité internationales pour simplifier les expéditions transfrontalières

– **En gestion des coûts:** Mettez en œuvre des versions réutilisables pour réduire les dépenses par expédition jusqu'à 60% au fil du temps

– **Pour la formation du personnel:** Développer des procédures de traitement simplifiées qui minimisent les erreurs et maximisent l’efficacité

> **Cas réel:** Un distributeur de produits alimentaires spécialisés a adopté des feuilles de glace carbonique le lendemain pour ses expéditions de fruits de mer haut de gamme en 2024. Ils ont réduit les pertes de produits liées à la température de 45% et réduit le temps de documentation d'expédition de 30%, améliorant considérablement leurs résultats.

## Comment mettre en œuvre correctement les feuilles de glace sèche Next Day dans vos opérations?

**Commencez par une évaluation approfondie de vos besoins thermiques, puis établir des protocoles standardisés pour l'activation, placement, et un suivi pour garantir des résultats cohérents.** Une mise en œuvre appropriée implique de former votre équipe sur des techniques de manipulation spécifiques et d'intégrer des contrôles de qualité à chaque étape du processus.. Cette approche systématique maximise les feuilles’ performances tout en minimisant les erreurs potentielles qui pourraient compromettre vos expéditions.

Commencez par cartographier vos itinéraires d'expédition et leur durée pour déterminer la quantité et la configuration de feuilles appropriées.. Par exemple, des temps de transit plus longs peuvent nécessiter des feuilles supplémentaires ou une isolation complémentaire. Selon 2024 données logistiques, les entreprises qui mettent en œuvre des procédures standardisées 40% moins d'écarts de température lors des expéditions critiques. Cette cohérence est vitale pour maintenir l’intégrité du produit, en particulier lors de l'expédition d'articles de grande valeur comme des produits pharmaceutiques ou du matériel de recherche.

### Cadre de stratégie de mise en œuvre

Élaborez un plan de mise en œuvre par étapes qui commence par des tests pilotes sur des itinéraires moins critiques avant de s'étendre à l'ensemble de vos opérations.. Cela vous permet d'affiner les procédures et de renforcer la confiance des équipes sans risquer des expéditions importantes.. Établir des indicateurs de réussite clairs, tels que les taux de cohérence de la température et le coût par expédition, pour mesurer l'impact de votre transition vers les plaques de glace carbonique du lendemain.

– **Pour l'intégration des processus:** Créer des guides visuels montrant le placement approprié des feuilles pour différents types de packages

– **En assurance qualité:** Mettre en œuvre des contrôles avant expédition pour vérifier l’activation des feuilles et les plages de température

– **Pour une amélioration continue:** Collectez des données de performances pour optimiser les quantités et les configurations de feuilles

> **Cas réel:** Un réseau de laboratoires médicaux a déployé des feuilles de glace carbonique le lendemain 15 emplacements dans 2024. Grâce à une mise en œuvre structurée, ils/elles ont réalisé 95% respect de la température dans toutes les expéditions et réduction des coûts d’emballage thermique en 35% dans les six mois.

## Quels facteurs de coût devriez-vous prendre en compte lors de l'utilisation de feuilles de glace carbonique Next Day?

**Évaluez à la fois l’investissement initial et les coûts opérationnels à long terme, y compris le prix d'achat, potentiel de réutilisation, frais de manutention, et des économies potentielles grâce à la réduction des pertes de produit.** Le coût total de possession s'avère souvent inférieur à celui de la glace carbonique traditionnelle en raison de la réduction des déchets et des exigences de manipulation plus simples.. En plus, prendre en compte la protection potentielle des revenus grâce à une meilleure fiabilité des expéditions et à la satisfaction des clients.

Même si le coût unitaire peut paraître plus élevé au départ, la nature réutilisable de nombreuses feuilles de glace carbonique le lendemain répartit cet investissement sur de nombreuses expéditions. Considérez également les coûts cachés de la glace carbonique traditionnelle, y compris des installations de stockage spéciales, formation sur les matières dangereuses, et dépenses de conformité réglementaire. L'analyse du secteur montre que les entreprises obtiennent généralement un retour sur investissement au sein 4-8 mois lors du passage à ces solutions thermiques avancées.

### Analyse complète des coûts

Créez une comparaison détaillée qui prend en compte tous les éléments de coût, y compris l'acquisition, stockage, manutention, expédition, et frais d'élimination. Pour les options réutilisables, calculer le coût par expédition en fonction du cycle de vie prévu des feuilles. Cette approche fournit une image financière plus précise que la simple comparaison des prix d'achat initiaux..

| Élément de coût | Glace sèche traditionnelle | Feuilles de glace carbonique du lendemain | Votre impact financier |

|—————-|———————|————————-|————————|

| Coût du matériel | Cohérent par expédition | Diminue avec la réutilisation | Baisse des dépenses à long terme |

| Frais de gestion | Plus haut (formation spéciale) | Procédures standards | Coûts de main d’œuvre réduits |

| Conformité réglementaire | Une paperasse importante | Exigences minimales | Gain de temps et moins de retards |

| Risque de perte de produit | Plus élevé grâce à la sublimation | Des performances maîtrisées | Moins de pertes financières |

### Stratégies d'optimisation budgétaire

– **Pour les gros utilisateurs:** Négocier les prix de gros avec les fournisseurs tout en maintenant les normes de qualité

– **En opérations mixtes:** Mettre en œuvre le suivi de l'utilisation pour identifier les opportunités d'optimisation dans tous les départements

– **Pour la planification budgétaire:** Élaborer des prévisions glissantes qui tiennent compte des variations saisonnières des volumes d’expédition

> **Cas réel:** Une entreprise de logistique d'essais cliniques a mené une analyse complète des coûts des feuilles de glace carbonique du lendemain en 2024. Ils ont découvert 40% réduction totale des coûts par rapport à la glace carbonique traditionnelle, principalement grâce à la réduction du temps de traitement et à l'élimination des frais liés aux matières dangereuses.

## 2025 Derniers développements en matière de solutions de contrôle de la température Next Day

Le marché des feuilles de banquise carbonique du lendemain évolue rapidement 2025, avec des innovations axées sur la surveillance intelligente, durabilité améliorée, et des fonctionnalités d'utilisation améliorées. Les nouvelles feuilles intègrent des capteurs IoT qui assurent un suivi de la température en temps réel tout au long du processus d'expédition., vous offrant une visibilité sans précédent sur vos expéditions’ condition. En plus, les fabricants développent des formulations plus respectueuses de l'environnement qui maintiennent les performances tout en réduisant l'impact environnemental.

La durabilité est devenue une priorité, avec des fournisseurs de premier plan introduisant des feuilles fabriquées à partir de matériaux recyclés et mettant en œuvre des programmes de reprise pour les produits en fin de vie. UN 2025 Un rapport de l'industrie a souligné que les entreprises utilisant ces feuilles de nouvelle génération réduisaient l'empreinte carbone de leurs emballages thermiques de 30% par rapport à 2024 solutions. Ces avancées s'alignent sur la pression réglementaire croissante et la demande des consommateurs pour des pratiques de chaîne d'approvisionnement plus écologiques dans tous les secteurs..

### Aperçu des innovations émergentes

– **Systèmes de surveillance intégrés:** Des tôles avec capteurs intégrés transmettent des données de température en temps réel à votre plateforme logistique, permettant une résolution proactive des problèmes

– **Science des matériaux avancée:** Les nouvelles formulations PCM offrent des plages de températures plus larges et une durée plus longue sans augmenter la taille ou le poids

– **Initiatives de durabilité:** Les fabricants mettent en œuvre des modèles d’économie circulaire, y compris les programmes de remise à neuf et de recyclage

L'analyse du marché indique que la demande de solutions plus intelligentes, Les couches de glace carbonique plus durables du lendemain augmenteront de 20% chaque année à travers 2026. Cette croissance entraîne une concurrence et une innovation accrues, ce qui se traduit par de meilleurs produits et des prix plus compétitifs pour des entreprises comme la vôtre. La convergence des performances, durabilité, et l'intégration numérique rend 2025 un moment idéal pour évaluer et mettre à niveau vos solutions d’expédition thermique.

## Questions fréquemment posées

**Combien de temps les feuilles de glace carbonique du lendemain maintiennent-elles généralement les températures?**

La plupart des feuilles maintiennent leur plage de température cible pendant 24-48 heures, en fonction des conditions ambiantes et de l'isolation. Les versions hautes performances peuvent étendre cela à 72 heures avec une mise en œuvre appropriée.

**Ces feuilles sont-elles réutilisables ou à usage unique?**

De nombreuses options sont réutilisables, offre 50+ cycles avec soin approprié. Vérifiez toujours les spécifications du fabricant pour connaître les attentes exactes en matière de cycle de vie et les exigences de recongélation..

**Quelles précautions de sécurité sont nécessaires lors de la manipulation de ces feuilles?**

Des gants de protection thermique standards sont recommandés, bien qu'ils soient plus sûrs que la glace carbonique traditionnelle. Évitez tout contact direct avec la peau et assurez une ventilation adéquate pendant le déballage.

**Ces feuilles peuvent-elles être utilisées pour les envois internationaux?**

Oui, la plupart sont conformes aux réglementations internationales en matière d'expédition car ils ne sont pas dangereux. Vérifiez toujours les exigences spécifiques du pays avant l’expédition.

**Comment puis-je me débarrasser correctement de ces draps?**

De nombreux fabricants proposent des programmes de recyclage. Pour élimination, suivre les réglementations locales pour les matériaux à changement de phase, qui sont généralement plus simples que les protocoles relatifs aux matières dangereuses.

## Résumé et recommandations

Les feuilles de glace carbonique du lendemain offrent un contrôle fiable de la température ultra-froide avec une sécurité et une efficacité opérationnelle améliorées par rapport à la glace carbonique traditionnelle.. Les principaux avantages incluent une manipulation plus facile, fardeau réglementaire réduit, et des économies potentielles grâce à la réutilisation. La mise en œuvre de ces fiches peut améliorer considérablement vos taux de réussite d'expédition tout en simplifiant vos processus de gestion thermique..

Commencez par évaluer vos exigences spécifiques en matière de température et vos modèles d'expédition.. Consultez des experts pour sélectionner les feuilles les plus appropriées à vos besoins, puis développer des procédures standardisées pour une mise en œuvre cohérente. Prendre ces mesures optimisera vos opérations d’expédition sensibles à la température et offrira des avantages commerciaux mesurables..

## À propos du tempk

Chez Tempk, nous sommes spécialisés dans les solutions avancées de chaîne du froid, y compris des feuilles de glace carbonique du lendemain conçues pour la fiabilité et l'efficacité. Nos produits intègrent les dernières 2025 des innovations pour vous aider à maintenir des températures parfaites tout en réduisant les coûts et la complexité. Avec une vaste expérience de l’industrie, nous aidons les entreprises à obtenir des résultats optimaux pour leurs besoins d'expédition les plus exigeants.

**Contactez nos spécialistes dès aujourd'hui** pour discuter de vos besoins spécifiques et découvrir comment nos solutions peuvent améliorer vos opérations..