Comment les fournitures d'emballage et les packs de glace carbonique améliorent-ils la logistique de la chaîne du froid?

Dans 2025, le transport de marchandises sensibles à la température telles que les produits pharmaceutiques, vaccins, and perishable foods demands state-of-the-art cold chain solutions. Parmi ces, packaging supplies and dry ice packs are critical components, ensuring goods maintain their required temperature throughout the supply chain. This article explores the role of dry ice and packaging materials in cold chain logistics, emphasizing their benefits, applications, et 2025 tendances.

-

The essential role of dry ice packs in maintaining temperature control during transport

-

How packaging supplies ensure product integrity and prevent spoilage

-

Sustainability efforts in cold chain logistics with eco-friendly packaging and dry ice options

-

Best practices for choosing and handling dry ice in cold chain logistics

What Are Dry Ice Packs and How Do They Improve Cold Chain Logistics?

Dry ice packs are solid CO₂ that sublimate at temperatures as low as -78.5°C (-109.3°F). This unique property makes them ideal for maintaining ultra-low temperatures during the transport of pharmaceuticals, vaccins, biologique, et les aliments périssables. Dry ice provides a long-lasting cooling solution, souvent jusqu'à 72 heures, without creating excess moisture, unlike conventional ice.

Benefits of Dry Ice Packs in Cold Chain Logistics

-

Puissance de refroidissement longue durée: Dry ice packs provide consistent cooling for extended periods, maintaining critical temperature ranges.

-

Aucun résidu liquide: Contrairement à la glace traditionnelle, la neige carbonique se sublime en gaz, ensuring no leaks or contamination during transport.

-

Manipulation facile: Avec un emballage approprié, dry ice is safe and easy to manage, reducing handling risks.

The Versatility of Dry Ice Packs Across Industries

-

Logistique pharmaceutique: Essential for shipping temperature-sensitive vaccines and clinical trial samples.

-

Frozen Food Logistics: Ideal for shipping seafood, viande, et légumes surgelés, ensuring they arrive in optimal condition.

-

Biotech Transport: Keeps biological samples at the required low temperatures during long-distance shipping.

| Application Type | Ideal Cooling Method | Durée | Avantage clé |

|---|---|---|---|

| Médicaments | Packs de glace sec | 48-72 HRS | Consistent ultra-low temperature |

| Logistique alimentaire | Packs de glace sec | 48 HRS | Prevents spoilage and maintains quality |

| Biotechnologie | Packs de glace sec | 48-72 HRS | Ensures sample viability |

How Do Packaging Supplies Ensure Safe Transport of Temperature-Sensitive Goods?

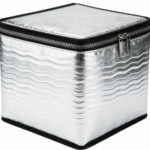

Packaging supplies such as insulated containers and vented packaging are essential for protecting dry ice and maintaining the required cooling environment. These materials help to prevent premature sublimation and control external temperature fluctuations, ensuring products stay within their desired temperature range.

Éléments clés d’un emballage efficace pour la chaîne du froid

-

Conteneurs isolés: These containers reduce the rate of heat transfer, Maintenir la stabilité de la température interne.

-

Emballage ventilé: Allows CO₂ gas from sublimating dry ice to escape safely, preventing pressure build-up and ensuring the cooling process remains effective.

-

Sealable Bags: Used to contain dry ice safely, these bags prevent gas leaks and maintain cooling power for longer durations.

Exemple: A global vaccine distributor increased delivery efficiency from 36 à 72 hours by integrating insulated containers with dry ice packs, significantly improving vaccine efficacy during transport.

How Packaging Supplies and Dry Ice Contribute to Sustainability?

As the cold chain logistics industry focuses more on sustainability in 2025, packaging supplies and dry ice have evolved. While traditional dry ice is made from CO₂ emissions captured from fossil fuels, companies now increasingly use CO₂ from renewable sources like biogas plants, reducing its environmental footprint.

Production de glace sèche durable

Dry ice now can be produced from captured emissions, including CO₂ from biogas plants. This process contributes to corporate sustainability goals by reducing greenhouse gas emissions and supports net-zero emissions targets for companies in various industries.

Solutions d'emballage respectueuses de l'environnement

The movement toward recyclable and biodegradable packaging materials is growing. Packaging supplies are now being made from renewable, eco-friendly sources, minimizing plastic waste and contributing to a more sustainable cold chain.

Sustainability Insight: A leading pharmaceutical company reduced packaging waste by 60% et réduire les coûts en 40% by switching to sustainable dry ice packaging solutions.

2025 Tendances de la logistique de la chaîne du froid: Innovations and Developments

Alors que le secteur de la logistique de la chaîne du froid continue d'évoluer, several trends and innovations are shaping the future. These advancements improve efficiency, durabilité, et conformité réglementaire, helping businesses stay competitive in a rapidly changing market.

S'orienter 1: Systèmes de surveillance intelligents

By incorporating Internet of Things (IoT) sensors into packaging, companies can track temperature and humidity in real-time, ensuring that products remain within the required conditions. Cela aide à prévenir la détérioration, improves regulatory compliance, and enhances supply chain visibility.

S'orienter 2: Systèmes de refroidissement hybrides

Combiner de la neige carbonique avec des matériaux à changement de phase (PCMS) enables a more stable temperature control system. Dry ice provides ultra-low temperatures, while PCMs smooth out temperature fluctuations, optimizing the lifespan of cooling systems during transit.

S'orienter 3: Automatisation dans l'emballage

Automation is revolutionizing the cold chain industry. Robotic systems are now being used for packaging, reducing human error and increasing the speed and efficiency of logistics operations, especially in high-volume industries like food distribution.

S'orienter 4: Matériaux durables

With a focus on reducing environmental impact, biodegradable and recyclable materials are becoming the norm in cold chain packaging. These innovations align with the circular economy, where resources are reused and repurposed rather than discarded.

| S'orienter | Description | Impact sur la chaîne du froid | Benefit for Your Operations |

|---|---|---|---|

| Systèmes de surveillance intelligents | Real-time tracking of conditions | Better visibility and compliance | Dégradation réduite, improved safety |

| Systèmes de refroidissement hybrides | Combination of dry ice + PCMS | More stable temperature control | Efficacité énergétique, économies de coûts |

| Automatisation dans l'emballage | Robotic systems for packaging and handling | Increased efficiency, reduced errors | Coûts de main d’œuvre réduits, faster throughput |

| Matériaux durables | Emballage biodégradable et recyclable | Réduction des déchets, un impact environnemental réduit | Empreinte carbone réduite, réduction des déchets |

Questions fréquemment posées (FAQ)

Q1: How long do dry ice packs last in cold chain transport?

Dry ice packs last between 48 à 72 hours depending on the insulation material and external conditions.

Q2: La glace sèche peut-elle être réutilisée?

Non, la neige carbonique se sublime directement en gaz CO₂, donc il ne peut pas être réutilisé. Cependant, the packaging may be reusable.

Q3: Quels matériaux d'emballage conviennent le mieux aux expéditions de glace carbonique?

Insulated containers made from materials like EPS foam or polyurethane are ideal for maintaining temperature stability during transport. Vented bags are also crucial to prevent pressure build-up.

Q4: Are eco-friendly dry ice options available?

Oui, dry ice can now be produced from CO₂ captured from renewable sources, significantly reducing its carbon footprint.

Conclusion et recommandations

Dry ice packs and packaging supplies are crucial in maintaining the integrity of temperature-sensitive goods across industries such as pharmaceuticals, biotechnologie, et logistique alimentaire. By adopting the latest innovations and best practices, you can enhance cold chain efficiency, réduire les coûts, and meet sustainability goals in 2025.

Étapes suivantes:

-

Transition to using sustainable dry ice solutions and eco-friendly packaging.

-

Invest in smart monitoring systems for real-time tracking of shipment conditions.

-

Optimize cold chain logistics by exploring hybrid cooling systems and automation.

À propos du tempk

Et tempk, we specialize in providing reliable and sustainable cold chain solutions, including dry ice packs and innovative packaging supplies. Our products are designed to ensure optimal temperature control during the transportation of sensitive goods.

Contactez-nous aujourd'hui to explore how our solutions can optimize your cold chain logistics operations.