Exportation de glacières pharmaceutiques: How Do You Ship Medicines Safely in 2026?

Pharmaceutical ice box export is not about moving boxes—it is about protecting patients.

Dans 2026, even short temperature deviations can reduce drug effectiveness by 20–40%, selon la formule. When you export vaccines, biologique, or temperature-sensitive medicines, packaging becomes a safety system, not a container. This guide shows you how to manage pharmaceutical ice box export safely, en conformité, and cost-effectively.

Cet article vous aidera:

-

Comprendre comment pharmaceutical cold chain ice box export really works

-

Identify the Exigences d'exportation de glacières médicales that matter most in 2026

-

Reduce risk during vaccine ice box international shipping

-

Control total cost without increasing compliance exposure

-

Choose packaging strategies that survive real-world delays

What Makes Pharmaceutical Ice Box Export Different?

Pharmaceutical ice box export requires zero guesswork.

Contrairement aux aliments ou aux biens de consommation, medicines have narrow temperature limits and strict documentation needs. One weak link—customs delay, reconditionnement, or poor insulation—can invalidate an entire shipment.

Think of pharmaceutical ice box export as a chain of trust.

Packaging is the foundation of that trust, and every handoff tests it.

Why Pharmaceuticals Require a Higher Export Standard

| Facteur | General Export | Exportation de glacières pharmaceutiques | Ce que cela signifie pour vous |

|---|---|---|---|

| Temperature tolerance | Moyen | Very narrow | Insulation must be precise |

| Pression de conformité | Modéré | Strict | Documentation is critical |

| Risk impact | Financial | Sécurité des patients | No margin for error |

| Validation | Rare | Obligatoire | Performance must be proven |

Practical Guidance You Can Apply

-

Longs routes: Design for worst-case delays, not planned transit

-

Multi-country exports: Align packaging with the strictest rule

-

High-value drugs: Prioritize stability over unit cost

Vrai exemple: A vaccine exporter avoided shipment rejection by upgrading insulation to handle a 48-hour unplanned airport delay.

Which Pharmaceuticals Commonly Use Ice Box Export?

Pharmaceutical ice box export is essential for medicines with narrow stability ranges.

These products often travel long distances before use.

| Type de produit | Gamme typique | Export Sensitivity | Packaging Priority |

|---|---|---|---|

| Vaccins | 2–8 ° C | Extremely high | Validated insulation |

| Biologique | 2–8 ° C | Très élevé | Hold-time stability |

| Thérapies cellulaires | En dessous de −20 °C | Critical | Advanced containment |

| Réactifs de diagnostic | 2–25 ° C | Moyen | Consistent protection |

Ce que cela signifie pour vous

-

Vaccines need documenté, not assumed, performance

-

Biologics care more about durée than thickness

-

Emerging therapies often require custom designs

What Are the Core Pharmaceutical Ice Box Export Requirements?

Pharmaceutical ice box export requirements focus on proof, traçabilité, and consistency.

Missing one element can invalidate a shipment.

Key Requirements You Must Meet

-

Validated thermal performance

-

Materials suitable for pharmaceutical use

-

Clear handling and temperature labeling

-

Complete export and quality documentation

Why Validation Is Non-Negotiable

Validation proves your ice box performs as claimed.

Sans, you rely on assumptions—and in pharmaceutical export, assumptions equal risk.

Think of validation like a flight test: you would not board a plane without one.

Conseils pratiques pour la conformité

-

Valider l'emballage before scaling exports

-

Keep records consistent across lanes

-

Train partners on handling instructions

Aperçu du cas: A biologics exporter reduced audit findings by standardizing validation records across all export routes.

How Does Pharmaceutical Ice Box Export Affect Cost?

Higher packaging cost often means lower total risk cost.

Focusing only on unit price usually leads to expensive failures.

| Cost Area | Low-Grade Box | Pharma-Grade Box | True Impact |

|---|---|---|---|

| Prix unitaire | Inférieur | Plus haut | Misleading |

| Perte de produit | Haut | Très faible | Critical |

| Compliance risk | Haut | Faible | Reputation |

| Re-shipments | Fréquent | Rare | Budget stability |

How Smart Exporters Control Total Cost

-

Reduce re-shipments caused by excursions

-

Prevent regulatory intervention with clean documents

-

Match insulation duration to route risk

Cost insight: Many exporters report up to 30% lower total landed cost after upgrading pharmaceutical ice boxes.

Should Pharmaceutical Ice Boxes Be Customized for Export?

Customization is often essential—not complex.

Standard boxes rarely match real routes.

| Scénario | Boîte standard | Customized Box | Better Choice |

|---|---|---|---|

| Short regional export | Travaux | Facultatif | Standard |

| Long international export | Risqué | Fiable | Personnalisé |

| Multi-stop handling | Fails often | Écurie | Personnalisé |

High-value customization options

-

Route-specific insulation duration

-

Internal layouts preventing vial movement

-

Moisture control for humid climates

How Do Delays Impact Pharmaceutical Ice Box Export?

Delays are the most underestimated risk.

Customs holds, inspections, and missed flights add time without warning.

Delay Risk Management Strategies

-

Design insulation for 1.5–2× planned transit time

-

Use clear labeling to avoid repacking

-

Pre-align documents with authorities

Vraie cas: A two-day customs delay caused no damage because the ice box was designed for 96-hour stability.

2026 Trends in Pharmaceutical Ice Box Export

Dans 2026, buyers demand proof, pas des promesses.

Développements clés

-

Validated reusable systems lower lifecycle cost

-

Longer-duration insulation reduces failure risk

-

Audit-ready packaging simplifies inspections

Perspicacité du marché:

Buyers increasingly prefer suppliers who reduce audit workload—even if unit prices are higher.

Common Pharmaceutical Ice Box Export Mistakes

Most failures come from underestimating reality.

Erreurs à éviter

-

Using food-grade boxes for pharmaceuticals

-

Designing only for planned transit time

-

Treating documentation as an afterthought

How You Avoid Them

-

Separate pharma packaging standards

-

Design for delays, not schedules

-

Integrate packaging and documentation planning

Questions fréquemment posées

What is the biggest risk in pharmaceutical ice box export?

Temperature excursions caused by delays. Packaging must absorb unplanned waiting time.

How long should a pharmaceutical ice box hold temperature?

Most exporters target 150–200% of planned transit time.

Are reusable ice boxes suitable for pharmaceuticals?

Oui, if validated and properly cleaned. Many exporters prefer them for consistency.

Résumé et recommandations

Pharmaceutical ice box export protects patients, not just products.

Dans 2026, success depends on validated performance, retarder la résilience, et une documentation claire.

Principaux à retenir

-

Packaging is part of patient safety

-

Validation reduces regulatory and financial risk

-

Better insulation lowers total cost

-

Customization improves reliability

What You Should Do Next

-

Review your export routes

-

Compare insulation duration with worst-case delays

-

Validate packaging before expansion

-

Work with partners who understand pharmaceutical risk

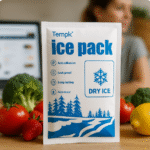

À propos du tempk

Et tempk, we support pharmaceutical exporters with ice box solutions designed for real-world cold chain challenges. Nous nous concentrons sur validated thermal performance, route-specific design, et audit-ready packaging systems. Our goal is to help you export medicines safely, constamment, and with confidence.

Prochaine étape: Consult a cold chain specialist to evaluate whether your current pharmaceutical ice box export setup truly meets 2026 attentes.