La glace carbonique est un puissant liquide de refroidissement largement utilisé dans le transport de produits périssables.. Cependant, une ventilation adéquate des paquets de glace carbonique est cruciale pour éviter une accumulation dangereuse de CO₂. Dans ce guide, nous explorerons comment ventiler en toute sécurité un emballage contenant de la neige carbonique, assurer le respect des 2025 normes d'expédition. Vous apprendrez l’importance de la ventilation, Conseils pratiques, et les réglementations de l'industrie.

-

Pourquoi la ventilation est nécessaire pour des expéditions de glace sèche en toute sécurité

-

Les différentes méthodes utilisées pour ventilation des paquets de glace carbonique

-

Comment se conformer aux dernières 2025 directives pour un transport en toute sécurité

-

Les meilleurs matériaux et emballages pour les conteneurs de glace carbonique ventilés

-

Conseils de sécurité clés pour prévenir les risques liés au CO₂

Pourquoi une ventilation est-elle nécessaire pour les expéditions de glace carbonique?

Une ventilation adéquate est une mesure de sécurité pour empêcher l'accumulation de CO₂ à l'intérieur de l'emballage.. Le dioxyde de carbone se sublime en gaz à un rythme rapide et doit s'échapper pour éviter l'accumulation de pression, ce qui peut provoquer l'éclatement de l'emballage ou la fuite de gaz dangereux dans la zone environnante. Le processus de ventilation permet de contrôler cette pression tout en maintenant l'intégrité du contenu à l'intérieur..

La ventilation garantit que le gaz peut s'échapper en toute sécurité de l'emballage., réduisant le risque d'étouffement ou d'explosion dû à une pression excessive. La ventilation doit être effectuée avec soin pour répondre aux normes réglementaires spécifiques, comme ceux de l'IATA et de l'UN1845, qui régissent les expéditions de glace carbonique.

Comprendre la sublimation et la ventilation de la glace carbonique

Quand la glace sèche sublime (passe du solide au gaz), il libère dioxyde de carbone (Co₂), ce qui peut entraîner de graves dangers s’il n’est pas correctement géré. Le volume de gaz augmente rapidement à mesure que la température augmente, et les conteneurs scellés peuvent devenir sous pression. L'emballage doit pouvoir libérer le gaz pour éviter une explosion.

Par exemple, 5 kg de neige carbonique peut produire jusqu'à 2,000 litres de CO₂ gaz. Sans ventilation, ce gaz pourrait provoquer des dégâts importants ou présenter un risque d'étouffement. Pour assurer la sécurité, les conteneurs doivent être conçus avec des évents respirants qui permettent une libération contrôlée de CO₂.

Méthodes de ventilation des paquets de glace carbonique

Il existe plusieurs méthodes utilisées pour ventiler les conteneurs de glace carbonique pendant le transport.:

-

Sacs micro-perforés: Ce sont des sacs dotés de minuscules trous qui permettent au gaz de s'échapper tout en empêchant la neige carbonique d'entrer directement en contact avec le contenu de l'emballage..

-

Inserts en mousse avec aérations: Les matériaux d'emballage tels que la mousse peuvent être conçus avec des trous ou des canaux intégrés qui permettent au CO₂ de s'évacuer tout en isolant la neige carbonique..

-

Couvercles amples: Certains conteneurs utilisent un couvercle qui n'est pas complètement scellé, permettre au gaz de s'échapper de l'emballage. Cette option doit être soigneusement surveillée pour garantir qu'elle n'affecte pas l'intégrité du contenu de l'emballage..

-

Systèmes de ventilation actifs: Les emballages plus grands peuvent utiliser des systèmes pour libérer du gaz en continu et de manière contrôlée.. Ceux-ci sont plus complexes mais offrent une sécurité maximale.

Matériaux d'emballage pour une ventilation sûre

Choisir le bon matériau d'emballage est essentiel pour garantir à la fois la sécurité de l'envoi et le respect de la réglementation.. Quelques considérations clés incluent:

-

Matériaux d'isolation: L'emballage doit fournir isolation pour maintenir la température de la neige carbonique tout en permettant au gaz de s'évacuer.

-

Durabilité: Assurez-vous que le colis peut résister à une manipulation brutale pendant le transport. Le matériau doit non seulement permettre l'évacuation du CO₂, mais également protéger contre les dommages physiques.

-

Conformité aux normes réglementaires: Les colis doivent respecter la dernière norme IATA, Et, et les directives du DOT pour l'expédition de glace carbonique, y compris des caractéristiques d'étiquetage et de ventilation appropriées.

Erreurs courantes lors de l'expédition de glace carbonique et comment les éviter

Certaines erreurs courantes qui se produisent lors des expéditions de glace carbonique incluent:

-

Utiliser des contenants hermétiques: Ceux-ci empêchent le gaz de s'échapper, conduisant à une accumulation de pression et à un risque d'accident. Assurez-vous toujours que votre colis est correctement ventilé..

-

Ventilation insuffisante: Ne pas laisser suffisamment d’espace ou de mécanismes pour que le CO₂ s’échappe peut avoir des conséquences dangereuses. Vérifiez toujours les mécanismes de ventilation pendant le processus d'emballage..

-

Étiquetage incorrect: Les colis contenant de la neige carbonique doivent être correctement étiquetés avec l'identification appropriée, y compris Et 1845 et le marquage « Dry Ice ». Un étiquetage incorrect peut retarder les expéditions et entraîner le non-respect des réglementations en matière d'expédition..

Étude de cas pratique: Une affaire récente impliquait une entreprise qui utilisait un conteneur hermétique pour expédier de la neige carbonique.. Le colis a explosé à cause de l'accumulation de pression, entraînant une perte de produit et des dommages importants. Cela souligne l'importance d'utiliser des conteneurs ventilés qui répondent aux exigences réglementaires..

2025 Lignes directrices sur la ventilation de la glace carbonique

À ce jour 2025, les réglementations relatives à la ventilation des paquets de glace carbonique ont été mises à jour pour souligner l'importance de la sécurité et de la conformité. Les compagnies maritimes doivent s'assurer que les colis sont équipés de systèmes de ventilation appropriés., soit passif, soit actif. Ces systèmes permettent au gaz de s'échapper à un rythme contrôlé, ce qui aide à prévenir une accumulation dangereuse de pression.

Principales mises à jour de 2025 Lignes directrices

-

Exigences accrues en matière de ventilation: Pour les expéditions plus importantes ou les expéditions impliquant plus de 5 kg de glace sèche, l'emballage doit inclure un système de ventilation qui libère du CO₂ à un taux spécifique.

-

Accent accru sur les voies d’évacuation des gaz: Matériaux tels que la mousse, sacs en tissu, et des doublures perforées sont plus fréquemment nécessaires pour les emballages plus grands afin de garantir que le gaz puisse s'échapper efficacement..

-

Exigences en matière d'étiquetage: De nouvelles directives appellent à des marquages plus clairs sur les emballages, précisant le quantité de neige carbonique et assurer le respect des normes de l'ONU 1845, la norme pour le transport de glace carbonique.

Dernières tendances de l'industrie

-

Utilisation d'emballages biodégradables et écologiques: De nombreuses entreprises s'orientent vers des solutions d'emballage durables pour la glace carbonique, qui comprend également des options de ventilation pour assurer la sécurité.

-

Technologie d'expédition intelligente: Des systèmes de surveillance en temps réel sont mis en œuvre dans les expéditions de glace carbonique, suivre la pression à l'intérieur des conteneurs pour garantir que les niveaux de CO₂ sont dans des limites sûres.

Insistance au marché

La demande mondiale de glace carbonique devrait augmenter avec la popularité croissante des denrées périssables., médicaments, et expéditions d'échantillons biologiques. Alors que les entreprises cherchent à assurer un transport sûr et conforme, l'accent mis sur les matériaux de ventilation et d'emballage continuera d'évoluer, intégrant une technologie de pointe pour améliorer les normes de sécurité.

Questions courantes sur la ventilation de la glace carbonique

Q1: Pourquoi la ventilation est-elle importante pour les expéditions de glace carbonique?

La ventilation est cruciale car elle permet dioxyde de carbone s'échapper pendant le processus de sublimation, empêchant l'accumulation de pression à l'intérieur de l'emballage. Sans ventilation, les conteneurs peuvent exploser ou laisser échapper des gaz dangereux.

Q2: Comment puis-je m'assurer que mon paquet de glace carbonique est correctement ventilé?

Assurez-vous que votre emballage comprend des matériaux respirants comme des sacs micro-perforés, inserts en mousse avec aérations, ou systèmes de ventilation actifs. Vérifiez toujours le respect des dernières réglementations.

Résumé et recommandations

-

Points principaux: Une ventilation adéquate est essentielle pour expédier de la neige carbonique en toute sécurité. Assurer le respect des 2025 lignes directrices, utiliser un emballage respirant, et étiquetez toujours correctement votre envoi.

-

Étapes suivantes: Passez en revue vos procédures d'expédition actuelles, mettre à jour l'emballage pour répondre aux exigences de ventilation, et vérifiez votre conformité aux dernières réglementations pour éviter les risques de sécurité et les amendes.

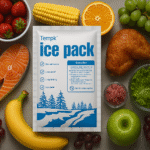

À propos du tempk

Nous sommes spécialisés dans la fourniture de solutions avancées d’emballage pour la chaîne du froid, y compris des conteneurs de glace carbonique conformes aux dernières 2025 directives de ventilation. Nos produits garantissent la sécurité, efficace, et transport écologique de marchandises sensibles à la température.

Contactez-nous pour des solutions sur mesure et des conseils d'experts sur vos besoins en matière d'expédition sous chaîne du froid.