Petit paquet de glace sèche: Paquet, Bateau, and Fly Safely in 2025

Mis à jour: Septembre 2, 2025. Si vous utilisez un small pack of dry ice to keep products frozen, this guide shows you exactly how to size it, emballer le, et rencontrer 2025 airline and carrier rules. You’ll get a rule‑of‑thumb calculator, safety steps that prevent damage, and simple compliance checklists tailored to real lanes. (Consolidated from Tempk internal drafts and 2025 regulatory notes.)

-

What counts as a small pack of dry ice? Practical ranges and hold‑time basics.

-

How to pack a small pack of dry ice? Un coffre-fort, step‑by‑step method with venting.

-

Can you fly with a small pack of dry ice? The 2.5 kg passenger limit made simple.

-

How much should you buy? A quick estimator for 24–72 h lanes.

-

When not to use dry ice? When −20 °C/−25 °C PCM beats dry ice for compliance.

What is a small pack of dry ice and when should you use it?

Réponse directe: A small pack of dry ice is typically 1–5 lb (0.45–2.27 kg) of solid CO₂ used to keep items frozen for short trips or 1–2‑day shipments. Planifier 5–10 lb par 24h in a standard hard cooler; warmer ambient, ouvertures fréquentes, and poor insulation raise the need. Use a vented container and gloves. Pour réfrigéré (2–8 ° C) marchandises, choisir +5 PCM °C instead to avoid freezing.

Pourquoi ça compte pour toi: You’ll keep ice cream, frozen entrées, or diagnostics solid for 24–36h when the cooler is pre‑chilled and stays closed. Dry ice is wrong for products that must not freeze (Beaucoup de vaccins, certains produits biologiques). Dans ces cas, phase‑change packs at +5 °C hold the safe range without DG paperwork.

Small pack of dry ice vs. gel/PCM—what should you pick?

Détails: Dry ice delivers ultra‑cold −78,5 ° C performance and high cooling capacity. PCMS (matériaux à changement de phase) hit a target melt point like −20 °C or +5 °C and avoid dangerous‑goods labels. Packs de gel hover near 0 °C for basic chilling. Choose based on the temperature your product actually needs.

| Cas d'utilisation | Glace sèche (small pack) | PCM (Par exemple, −25°C / +5 ° C) | Ce que cela signifie pour vous |

|---|---|---|---|

| Keep ice cream rock‑hard | ✅ Best | ❌ Too warm | Deep‑freeze for DTC and day‑plus lanes |

| Diagnostic < −20 ° C | ✅ Works | ✅ Works | Pick DG (glace carbonique) vs non‑DG (PCM) |

| 2–8°C médicaments | ❌ Too cold | ✅ Best | Avoid freezing risk and DG handling |

Conseils et suggestions pratiques

-

Grocery or meal kit: Use a small pack of dry ice near the frozen zone; add +5 °C PCM near chilled items to prevent over‑freezing.

-

Vols courts: Stay ≤ 2,5 kg (5.5 kg) total, Utiliser un ventilé étui rigide, and mark the net kg on the outside.

-

Panne de courant: Stage a small pack of dry ice in a ventilé refroidisseur dur; check every 12–18h and add regular ice to stretch hold time.

Cas réel: A bakery shipped frozen croissants using ~4 kg dry ice in a 24‑qt cooler with a barrier sheet and void fill. Après 28 H par temps doux, the order arrived solid‑frozen, labels intact, vents open.

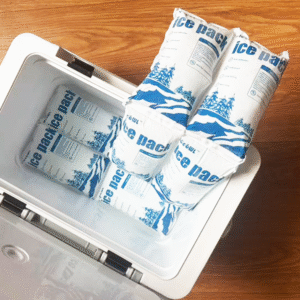

How do you pack a small pack of dry ice safely?

Réponse directe: Préchauffeur, envelopper, lieu, remplir les vides, secouer, et étiqueter. Wrap blocks in paper to slow loss. Mettez de la glace carbonique en haut to keep items frozen; on bottom with a barrier to keep them just cold. Keep lids closed and jamais sceller hermétiquement. Marque «Dioxyde de glace sèche / carbone, solide" et le Kg net lors de l'expédition.

Explain it like a friend: Think of dry ice as a portable ultra‑freezer that breathes out CO₂. You want that gas to escape and the cold to couler around your payload. A simple paper wrap slows sublimation. A thin barrière en carton prevents label scuffs and “freezer burn.” Fill voids so warm air can’t pool. Shade the shipper, et vent the gasket or drain.

Small pack of dry ice—step‑by‑step checklist

Detailed steps:

-

Préchauffeur the cooler 2–12 h (or use sacrificial ice).

-

Envelopper the small pack of dry ice in newspaper or a paper bag.

-

Lieu & barrière: top to freeze; bottom to chill; add a thin barrier layer.

-

Remplir les vides with paper to cut air space.

-

Secouer the container—jamais hermétique; leave a path for CO₂ to escape.

-

Marque & peser: « Glace carbonique / Dioxyde de carbone, solide,» UN1845, et Kg net.

| Élément d'emballage | Bonne pratique | Pourquoi ça compte | For your shipment |

|---|---|---|---|

| Wrapping | Newspaper/towel wrap | Ralentit la sublimation; manipulation plus sûre | Durée de vie plus longue; fewer scuffs |

| Placement | Top to freeze; bottom to chill | Uses natural cold airflow | Tailor to product risk |

| Ventilation | Gasket or drain left open | Co₂ doit s'échapper | Avoids pressure damage |

Can you fly with a small pack of dry ice?

Réponse directe: Yes—up to 2.5 kg (5.5 kg) par passager avec approbation des compagnies aériennes, dans un ventilé package marked UN1845 avec Kg net. Air cargo uses Voici pi954 and Class 9 labeling; domestic ground in the U.S. generally follows 49 CFR173.217 packaging and marking.

Ce que cela signifie pour vous: You can carry a small pack of dry ice on a flight if you secouer the container and write the weight. Pour le fret aérien, carriers publish simple checklists—use them as your final pre‑tender audit. Pour les charges mixtes, ajouter packs de gel to extend cooling without increasing dry ice weight.

Airline & shipper quick‑check

-

Vols de passagers: ≤ 2.5 kg per person; emballage ventilé et marqué.

-

Fret aérien: Étiquette de classe9, UN1845, Nom d'expédition approprié, Kg net, vented per PI 954.

-

Terre (NOUS.): Not regulated as hazardous for terrain domestique, yet packaging/marking rules still apply.

How much small pack of dry ice do you need?

Réponse directe: Commencer par 5–10 lb par 24h in a typical insulated cooler. Scale with volume, chaleur ambiante, et ouvertures du couvercle. Les blocs durent plus longtemps que les pastilles; wrapping slows sublimation.

Pourquoi ça marche: Many supplier charts and field tests align near ~2%/hour loss under common conditions. Qualité de l'isolation, taux de remplissage, and sun exposure move the number. Validate on your lane with a data logger, then right‑size by ±20%.

Mini‑calculator: small pack of dry ice (règle)

Exemple: 24 H, basic hard cooler, ambiance douce, pre‑frozen load → ~6.5 lb → buy 7–9lb for buffer.

| Taille plus froide | 24 h plan | 36 h plan | Ce que cela signifie |

|---|---|---|---|

| 12–20 qt | 5–8 lb | 8–12 lb | True “small pack” territory; pre‑chill helps |

| 24–30qt | 7–10 lb | 10–15 lb | Minimize openings; envelopper des blocs |

| 45–50 qt | 12–18 livres | 18–25 lb | Consider two blocks + remplissage de vide |

Quand devriez-vous pas use a small pack of dry ice?

Réponse directe: Évitez la glace carbonique when products are sensitive to freezing (many 2–8 °C vaccines), when packaging would be hermétique, or when rooms/vehicles are poorly ventilated. Utiliser +5 PCM °C for 2–8 °C and −20 °C/−25 °C PCMs for frozen lanes that must avoid DG handling.

Pourquoi ça compte: You’ll reduce refusals, simplify returns, and improve recipient safety. −25 ° C PCM often matches overnight frozen performance without CO₂ off‑gassing or UN1845 labels—ideal for frequent air moves.

Choose by lane—small pack of dry ice vs. −25 ° C PCM

| But | Meilleur choix | Pourquoi | Votre déménagement |

|---|---|---|---|

| Du jour au lendemain, < −15 ° C | Glace sèche ou −20 ° C PCM | Both hit frozen; DG vs. non‑DG tradeoff | If flying often, trial PCM |

| 24–48h, < −20 ° C | −25 ° C PCM | Réutilisable; airline‑friendly | Charge packs; valider |

| ≥ 48 h, profond | Glace sèche | Plus froid; densité énergétique plus élevée | Apply UN1845 + Pi954 |

2025 Développements et tendances: small pack of dry ice

Aperçu de la tendance: Des transporteurs rafraîchis dangerous‑goods checklists and reiterated UN1845, marquage du kg net, et ventilation. Le 2.5 kg passenger cap remains. Entre-temps, sub‑zero PCM options expanded as practical “dry‑ice substitutes” for some lanes. Attendez-vous à plus de packs hybrides: small pack of dry ice + PCM sleeves to balance performance, coût, et conformité.

Dernier progrès en un coup d'œil

-

Aides au travail des transporteurs: 2025 checklists clarify label placement and acceptance steps.

-

Stable passenger rules: Le 2.5 kg limit with venting continues across airlines.

-

PCM growth: −25 °C gels reduce refusals and simplify returns for common overnight routes.

Perspicacité du marché: Demand for small‑format frozen shipping remains high across DTC food, diagnostic, et pharmaceutique spécialisée. Companies increasingly select non‑DG PCMs when “frozen enough” is acceptable, reserving dry ice for profond ou 48 h+ voies.

Questions fréquemment posées

Q1: How long does a small pack of dry ice last?

Plan 5–10 lb par 24h in a hard cooler. Pre‑chilling and fewer openings extend life.

Q2: Can I fly with a small pack of dry ice?

Oui. ≤ 2,5 kg (5.5 kg) par passager avec approbation des compagnies aériennes, ventilé emballer, et Kg net marqué.

Q3: Do I need a DG declaration for air cargo?

Souvent Non for dry ice used only as a coolant; labels/marks still required (UN1845, Classe9, Kg net). Check the operator job aid.

Q4: Blocks or pellets for a small pack of dry ice?

Les blocs durent plus longtemps; pellets chill faster but sublimate sooner. Wrap either to slow loss.

Q5: What’s safer for 2–8 °C?

Not dry ice. Utiliser +5 PCM °C and proper conditioning to avoid freezing.

Résumé et recommandations

Points clés: UN small pack of dry ice est idéal pour 24–36h frozen control when you pré-refroidissement, envelopper, secouer, et étiqueter. Suivre UN1845/Class 9 et Net - kg règles pour l'air; cap baggage at 2.5 kg. Utiliser −25 °C PCMs when you want frozen control without DG complexity.

Étapes suivantes (CTA):

-

Use the mini‑calculator to size your small pack of dry ice.

-

Print our packing SOP and airline checklist for your team.

-

Pilot with a data logger, then tune ±20%.

-

Parlez à un spécialiste du tempk for lane‑by‑lane coolant plans.

À propos du tempk

We engineer validated packouts for congelé, glacé, and CRT expéditions. Our team blends thermal modeling with qualified shippers and the right coolant—small pack of dry ice ou −25 ° C PCM—to hit target temperatures with fewer touchpoints and lower landed cost. Nous nous concentrons sur evidence‑based SOPs et fast pilot‑to‑scale for DTC food, diagnostic, et pharmaceutique spécialisée.