Depuis des décennies, Styrofoam shipping boxes et Grands conteneurs d'expédition en polystyrène have been the backbone of temperature-sensitive logistics. Fabriqué à partir de polystyrène expansé (PSE), ces légers, cost-effective solutions are widely used to transport perishable goods like pharmaceuticals, fruit de mer, et aliments surgelés. Cependant, as industries prioritize sustainability and efficiency, businesses are exploring alternatives like Tempk’s thermal bags to address Styrofoam’s limitations while maintaining thermal performance.

Why Styrofoam Dominates Cold Chain Shipping

Styrofoam’s popularity stems from its unique properties:

- Isolation exceptionnelle: EPS foam’s air-trapping structure delays heat transfer, Garder le contenu congelé ou réfrigéré pendant 24 à 72 heures.

- Absorption des chocs: Protects fragile items like lab samples or delicate produce during rough transit.

- Abordabilité: Lower upfront costs compared to advanced materials like vacuum-insulated panels.

- Tailles personnalisées: Scalable designs accommodate everything from small medical shipments to bulky seafood crates.

Challenges of Styrofoam Boxes and Containers

Despite their utility, Styrofoam raises significant concerns:

- Impact environnemental: Non-biodegradable and rarely recycled, EPS contributes to landfill waste and microplastic pollution.

- Abondance: Large containers occupy excessive storage and shipping space, raising logistics costs.

- Single-Use Bias: Most Styrofoam boxes are discarded after one trip, exacerbating sustainability issues.

Industries Relying on Styrofoam Solutions

- Nourriture & Boisson: Fruit de mer, Repas surgelés, laitier, et produire.

- Soins de santé: Vaccins, biologique, et médicaments sensibles à la température.

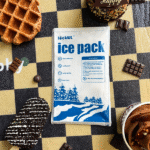

- Commerce électronique: Kits de repas, chocolats gastronomiques, et marchandises spécialisées.

- Agriculture: Fleurs, plantes, et cultures vivantes.

Sacs thermiques tempk: Durable, Agile Cold Chain Alternatives

Tandis que le styrométrie excelle dans l'expédition en vrac, Sacs thermiques de Tempk provide a modern, eco-conscious solution for last-mile delivery, short-haul trips, ou des expéditions plus petites. Conçu pour compléter ou remplacer les conteneurs traditionnels, Tempk’s products bridge the gap between performance and sustainability:

Why Tempk Thermal Bags Outperform Styrofoam:

- Matériaux respectueux de l'environnement: Réutilisable, recyclable fabrics minimize waste versus single-use Styrofoam.

- Léger & Compact: Save up to 50% storage space and reduce shipping costs.

- Isolation supérieure: Multi-layered foam and reflective liners maintain safe temperatures for 8–12 hours.

- Fuite & Hygiénique: Les intérieurs imperméables empêchent les déversements; wipe-clean surfaces ensure sanitation.

- Marque de marque personnalisée: Add logos, couleurs, or QR codes to enhance brand visibility during deliveries.

- Rentabilité: La construction durable prend en charge des centaines d'utilisations, réduire les dépenses à long terme.

Conclusion

Styrofoam shipping boxes and containers remain vital for large-scale, long-distance cold chain logistics. Cependant, businesses seeking to reduce environmental impact, optimize storage, and enhance last-mile efficiency can seamlessly integrate Tempk’s thermal bags into their operations. With advanced insulation, Designs réutilisables, and branding flexibility, Tempk empowers companies to meet modern demands for sustainability and reliability.

Choose Tempk—Innovative Thermal Solutions for a Greener, Smarter Supply Chain.