Garder les denrées périssables à la bonne température pendant le transport peut s'avérer intimidant, mais pack de glace carbonique à contrôle de température feuilles rendre les choses plus faciles que jamais. Ces couvertures flexibles remplies de dioxyde de carbone solide offrent des conditions ultra froides jusqu'à −78,5 °C et maintiennent les marchandises congelées pendant des jours sans laisser de dégâts aqueux.. Alors que la demande mondiale de produits biologiques, les vaccins et les aliments surgelés augmentent, le marché de l'emballage de la chaîne du froid devrait atteindre USD 32.29 milliards 2025, stimuler l'innovation dans le domaine des emballages à température contrôlée. Ce guide explique ce que sont les calottes carboniques, Comment ils fonctionnent, Pourquoi ils comptent, et comment les utiliser en toute sécurité. Vous découvrirez les dernières réglementations, tendances émergentes, et des mesures pratiques pour protéger vos expéditions afin que vous puissiez expédier en toute confiance et de manière durable..

Qu'est-ce qu'une feuille de glace carbonique à contrôle de température? Comprenez comment le CO₂ solide se sublime pour refroidir vos produits et pourquoi ces feuilles sont différentes des packs de gel.

Comment utiliser les plaques de glace carbonique en toute sécurité? Apprenez les meilleures pratiques en matière d'emballage, ventilation, équipement de protection et élimination.

Quand devriez-vous choisir la glace carbonique plutôt que les matériaux à changement de phase ou les packs de gel? Comparez les plages de température, durée, dangers et durabilité.

Quelles réglementations s'appliquent dans 2025? Obtenez un aperçu concis de l’IATA PI 954, UN1845 et autres règles de sécurité.

Quelles sont les dernières innovations et tendances du marché? Explorer la surveillance IoT, les emballages intelligents et les initiatives durables stimulent la croissance.

Que sont les feuilles de glace carbonique à contrôle de température et comment fonctionnent-elles ??

Feuilles de glace sèche à contrôle de température sont des couvertures ou des draps flexibles qui contiennent des poches de dioxyde de carbone solide. Lorsque les feuilles sont activées et gelées, le CO₂ solide se sublime, c'est-à-dire, il passe directement d'un solide à un gaz, absorbant une grande quantité de chaleur de l'environnement. Ce processus maintient votre cargaison extrêmement froide sans laisser d'eau liquide derrière elle.. Contrairement aux packs de gel traditionnels qui fondent 0 °C, les calottes carboniques maintiennent des températures jusqu'à -78,5 °C pendant une période allant jusqu'à 72 heures, ce qui les rend idéaux pour expédier des vaccins, produits biologiques et aliments surgelés.

Ces feuilles fonctionnent parce que l'enthalpie de sublimation pour la neige carbonique est d'environ 571 kJ/kg. Quand le CO₂ se sublime, il absorbe cette énergie, abaisser la température ambiante. La conception flexible des feuilles leur permet de s'enrouler autour de la cargaison, fournissant un refroidissement uniforme et minimisant les points chauds. Parce que le CO₂ se sublime directement en gaz, il n'y a pas d'eau de fonte susceptible de fuir ou d'endommager l'emballage, un avantage majeur par rapport aux packs de glace à base d'eau.

Calotte carbonique vs. sac de glace traditionnel: principales différences

Le tableau ci-dessous montre comment les feuilles de glace carbonique surpassent les packs de glace conventionnels à base de gel ou d'eau.:

| Fonctionnalité | Feuille de glace carbonique | Pack de glace traditionnel | Signification pour vous |

| Plage de température | Maintient des températures ultra froides autour de −78,5 °C | Plane près 0 °C (eau gelée) | La glace carbonique permet l'expédition des vaccins, produits biologiques et autres produits nécessitant des températures inférieures à zéro, alors que les packs de gel sont limités aux produits réfrigérés. |

| Durée de refroidissement | Reste froid jusqu'à 24 - 72 heures en fonction de la taille des plaques et de l'isolation | Dure généralement 6 à 12 heures | Moins de recharges et un risque réduit d’excursions de température signifient des coûts logistiques inférieurs et une meilleure qualité de produit. |

| Résidu | Se sublime directement en gaz – aucun résidu liquide | Fond dans l'eau, laisser un emballage humide | L'absence d'humidité empêche la contamination du produit et l'endommagement des étiquettes ou des composants électroniques. |

| Réutilisabilité | Usage unique; la glace carbonique se sublime complètement | Les packs de gel réutilisables peuvent être recongelés | La glace carbonique coûte plus cher par expédition mais offre des températures ultra froides; les packs de gel permettent d'économiser de l'argent pour les charges réfrigérées. |

| Meilleurs cas d'utilisation | Vaccins, biologique, aliments surgelés et échantillons de recherche | Aliments réfrigérés, boissons et autres biens qui nécessitent uniquement une réfrigération | La sélection du bon réfrigérant garantit la conformité réglementaire et préserve l'efficacité du produit. |

Conseils pratiques et conseils d'utilisation

Conteneurs et produits pré-refroidis: Réfrigérez votre boîte isotherme et votre charge utile avant d'ajouter de la neige carbonique. Cela évite le gaspillage de réfrigérant lors du refroidissement du conteneur..

Utilisez la méthode sandwich: Placez une couche de neige carbonique au fond, vos marchandises au milieu, et une autre couche par dessus. Pour feuilles fines, enroulez-les sur les côtés pour un refroidissement plus uniforme.

Assurer une bonne ventilation: La glace sèche sublime dans le gaz co₂. Utilisez toujours des récipients ventilés ou retirez les bouchons d'aération pour que le gaz puisse s'échapper.. Ne scellez jamais de glace carbonique dans une boîte hermétique; l'accumulation de pression peut provoquer une explosion.

Portez un équipement de protection: La glace carbonique est extrêmement froide et peut provoquer des engelures. Portez des gants et des lunettes isolants lors de la manipulation et évitez tout contact direct avec la peau..

Éliminer en toute sécurité: Laissez la neige carbonique non utilisée se sublimer dans un endroit bien aéré. Ne le placez pas dans les éviers ou les ordures où il pourrait endommager la plomberie.

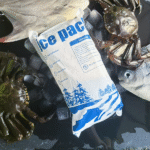

Vraie cas: Un exportateur de fruits de mer a utilisé des feuilles de glace carbonique pour expédier du poisson congelé à travers le pays.. Par conteneurs de pré-refroidissement, superposer les feuilles, et aérer correctement, l'entreprise a maintenu la qualité du produit et évité la décongélation, répondant à la fois aux règles de sécurité et aux attentes des clients

Pourquoi choisir des feuilles de glace carbonique plutôt que des matériaux à changement de phase ou des packs de gel?

La glace carbonique offre des températures ultra basses que les réfrigérants alternatifs ne peuvent égaler. Matériaux à changement de phase (PCMS) sont des substances conçues qui absorbent et libèrent de la chaleur à des plages de température spécifiques, typiquement 2 °C à 8 °C ou –20 °C. Packs de gel (à base d'eau ou de glycol) geler près 0 °C et offre un refroidissement modeste. Le tableau ci-dessous compare ces options:

| Réfrigérant | Plage de température | Durée | Classification des dangers | Réutilisabilité | Quand choisir |

| Feuille de glace carbonique | ≈ −78,5 °C | 24 - 72 h en fonction de l'isolation | Classe 9 matières dangereuses (UN1845) | Usage unique (Limères soudantes) | Idéal pour les envois ultra froids tels que les vaccins, biologique, thérapies géniques et aliments surgelés. |

| Matériau à changement de phase (PCM) | 2 °C à 8 °C ou –20 °C | 24 - 96 h avec des contenants réutilisables | Généralement non dangereux | Réutilisable; nécessite un conditionnement | Convient aux produits sensibles à la température qui doivent rester dans des plages étroites (biologique, réactifs, échantillons cliniques). |

| Pack de gel | 0 °C à 4 °C | 6 - 24 h | Non dangereux | Réutilisable | Idéal pour les aliments réfrigérés, boissons et denrées périssables non critiques. |

La neige carbonique produit un froid plus profond car le CO₂ se sublime à –78,5 °C. PCMS, tout en étant réutilisable, ne peut pas atteindre des températures aussi basses et nécessite un préconditionnement avant utilisation. Les packs de gel sont peu coûteux et faciles à réutiliser, mais risquent de fondre et de fuir de l'eau.. En plus, Les PCM et les packs de gel ne sont pas classés comme dangereux, simplifier la conformité des expéditions. La glace carbonique nécessite un étiquetage et une documentation des marchandises dangereuses selon l'IATA, Réglementations DOT et ONU.

Matériaux à changement de phase et packs de gel: quand ils comptent

Les PCM sont un choix judicieux lorsque vous devez maintenir une plage de température stricte, comme 2 °C à 8 °C pour les vaccins – ou –20 °C pour certains produits biologiques. Les PCM se solidifient ou fondent à ces points de consigne, offrant une stabilité thermique pendant de nombreuses heures. Ils sont réutilisables et généralement classés comme non dangereux, réduire les restrictions d'expédition et les problèmes d'élimination.

Les packs de gel offrent un refroidissement modeste et conviennent mieux aux produits réfrigérés comme les livraisons de kits repas, boissons et produits frais. Ils sont largement disponibles, peu coûteux et sûr à manipuler. Cependant, ils ne peuvent pas maintenir des conditions gelées et laissent des résidus d’eau lorsqu’ils fondent.

Exemple de cas: Un fabricant de biotechnologie expédiant des kits d'essais cliniques à 2 °C à 8 °C passé des packs de gel aux conteneurs PCM. Le résultat n'a été aucune excursion de température et un 40 % réduction des coûts après dix expéditions grâce à la réutilisation des packs PCM.

Principales exigences réglementaires et de sécurité pour 2025

L'expédition avec de la neige carbonique est réglementée car le CO₂ solide est classé dans la classe 9 matière dangereuse sous UN1845. L'Association du transport aérien international (Iata) Instruction d'emballage 954 et le Règlement sur les marchandises dangereuses précise comment la neige carbonique doit être emballée., étiqueté et déclaré. Dans 2025, les règles se durcissent encore:

Exigences clés

Ventilation: Les emballages doivent permettre l'évacuation du gaz CO₂ pour éviter une accumulation dangereuse de pression.. N’utilisez jamais de conteneurs hermétiques pour les expéditions de glace carbonique.

Étiquetage approprié: Chaque envoi doit porter le code UN1845, le poids net de glace carbonique, Et la classe 9 symbole de danger. Les étiquettes doivent être au minimum 100 mm carré et placé du même côté de l'emballage que l'appellation commerciale.

Matériaux d'emballage: Utiliser fort, des contenants isothermes qui peuvent résister au froid extrême et permettre une sublimation en toute sécurité, tels que des glacières en polystyrène ou des boîtes doublées de plastique.

Limites de poids: Les transporteurs aériens limitent la glace carbonique à 200 kg par forfait. Une surcharge peut entraîner des amendes ou un refus de transport.

Documentation: Les expéditeurs doivent préciser le poids net de glace sèche et marquer « Dioxyde de carbone, solide » sur les factures de transport aérien. Certaines expéditions peuvent nécessiter une déclaration de marchandises dangereuses.

Processus d'emballage étape par étape

Sélectionnez un conteneur isotherme: Choisissez un contenant qui peut tolérer un froid extrême sans se fissurer. Les glacières en polystyrène ou en plastique sont des choix courants.

Évacuer le conteneur: Percez ou ouvrez des trous d’aération pour permettre au gaz CO₂ de s’échapper. Ne fermez jamais complètement le récipient.

Placez la plaque de glace carbonique dessus: Placer de la neige carbonique au-dessus du produit; parce que le gaz CO₂ coule, le placer dessus aide à maintenir la bonne température.

Sceller et étiqueter: Sécurisez le conteneur, en s'assurant qu'il reste ventilé, et apposez l'étiquette UN1845, Classe 9 symbole et informations sur le poids net.

Vérifier le poids: Confirmez que le poids total de glace sèche ne dépasse pas celui de la compagnie aérienne. 200 limite de kg.

Utiliser des listes de contrôle: Suivez la liste de contrôle IATA ou les SOP de votre entreprise pour documenter la conformité.

| Exigence | Détails | Ce que cela signifie pour vous |

| Étiquette UN1845 | Marquez le paquet « Dioxyde de carbone, solide (glace carbonique)" avec poids net | Garantit que les régulateurs et les transporteurs savent que votre envoi contient de la neige carbonique. |

| Emballage ventilé | Les conteneurs doivent permettre au gaz CO₂ de s'échapper | Empêche l'accumulation de pression et les explosions. |

| Limite de poids | Pas plus que 200 kg de glace sèche par colis | Rester dans les limites évite les restrictions de vol et les amendes. |

| Documentation | Le poids net précis et les détails de l'expéditeur doivent apparaître sur la facture de transport aérien | Indispensable pour les audits, dédouanement et réclamations d'assurance. |

Erreurs courantes et comment les éviter

Mauvaise ventilation: Ne pas ventiler les emballages peut provoquer une accumulation de CO₂ et une rupture de l'emballage.. Incluez toujours des trous de ventilation ou des matériaux respirants.

Étiquetage incorrect: Les étiquettes UN1845 manquantes ou incorrectes retardent les expéditions ou déclenchent des amendes. Vérifiez l'étiquetage avant l'expédition.

Surcharge: Dépasser le 200 La limite de poids en kg peut entraîner un non-respect et des vols annulés. Vérifiez le poids et utilisez plusieurs colis si nécessaire.

Mauvais matériaux d'emballage: L’utilisation d’une isolation non approuvée ou endommagée provoque des fluctuations de température. Investissez dans des conteneurs de haute qualité conçus pour la glace carbonique.

Sauter une formation: Le personnel doit être formé à la manipulation des matières dangereuses. Fournir des mises à jour régulières des SOP et des rappels de sécurité.

Vraie cas: Une entreprise pharmaceutique a amélioré ses résultats d'audit et réduit les délais d'expédition en suivant strictement les IP 954 lignes directrices : conteneurs de ventilation, étiqueter correctement, et limiter le poids de la glace carbonique.

Derniers développements et tendances pour 2025

Aperçu de la tendance

Le marché de l’emballage sous chaîne du froid est en pleine expansion. Mordor Intelligence rapporte que le marché vaudra en USD 32.29 milliards en 2025 et grandir en USD 48.93 milliards 2030, un TCAC de 8.67 %. La croissance est alimentée par la hausse des volumes de produits biologiques, Expansion des épiceries en ligne et programmes mondiaux de vaccination. Ces conducteurs exigent un emballage validé, surveillance avancée de la température et matériaux durables.

Les dernières innovations en un coup d'œil

Appareils de surveillance intelligents: Les conteneurs passifs intègrent désormais des capteurs IoT qui transmettent des données de température en direct. Le conteneur hybride de SkyCell peut fonctionner pendant 270 heures et diffusez des données en temps réel, attirer des assureurs qui récompensent la réduction des risques.

Lettres de transport aérien numériques et documentation électronique: De plus en plus de régions adoptent l'eAWB, ce qui nécessite un suivi numérique précis et réduit la paperasse.

Matériaux durables: Les matériaux à changement de phase biosourcés et les isolants recyclables gagnent du terrain. Lancement des doublures climaliner recyclables en bordure de rue en 2024 livrer 72 heures de protection thermique tout en répondant aux exigences de recyclage. Les entreprises se tournent vers des emballages de glace carbonique biodégradables et des expéditeurs réutilisables.

Optimisation des itinéraires grâce à l'IA: Les entreprises de livraison telles que HelloFresh utilisent l'IA pour adapter les configurations d'emballage aux données météorologiques et d'itinéraire., réduire les écarts de température et les déchets d'emballage.

Générateurs de glace carbonique portables: Des générateurs portables permettent la production de neige carbonique sur site, réduire les émissions et les coûts du transport.

Insistance au marché

Le marché est motivé par plusieurs facteurs:

Logistique des produits biologiques et de la thérapie génique: Près de la moitié des nouveaux produits pharmaceutiques nécessitent un contrôle de la température, et les thérapies avancées nécessitent des conditions cryogéniques inférieures à –150 °C. Des produits comme l’expéditeur cryogénique HV3 de Cryoport lancés en janvier 2025 illustrer la nécessité de conceptions spécialisées.

Épicerie e-commerce: L'explosion de la livraison d'épicerie et de kits de repas en ligne augmente la demande d'espace efficace, isolation légère qui résiste à la variabilité du dernier kilomètre. L'emballage piloté par l'IA permet d'optimiser les conditions météorologiques et les itinéraires..

Programmes mondiaux de vaccination: Initiatives de Gavi, L'UNICEF et l'OMS exigent des emballages validés pour la chaîne du froid qui fonctionnent dans les zones reculées. Des cliniques alimentées à l'énergie solaire en Éthiopie mettent en lumière les défis en matière d'infrastructure et stimulent l'innovation dans les technologies de refroidissement portables.

ESG et durabilité: Les objectifs environnementaux des entreprises stimulent l’adoption d’expéditeurs passifs réutilisables et de matériaux biosourcés. Les réglementations de l'UE exigent désormais la recyclabilité totale des emballages par 2030, pousser les fournisseurs vers des solutions basées sur la fibre.

Indicateurs intelligents et assurance: Adoption d’indicateurs intelligents par les assureurs (Par exemple, Le capteur de sémaglutide de Timestrip) aide à surveiller les écarts de température et à réduire les réclamations.

Questions fréquemment posées

Q1: Combien de temps durent les feuilles de glace carbonique à contrôle de température?

Les calottes carboniques maintiennent généralement des températures ultra froides pendant 24 heures par feuille; plusieurs feuilles ou couches peuvent prolonger le refroidissement jusqu'à 72 heures. Combinez-les avec une isolation de haute qualité pour maximiser la durée.

Q2: Les feuilles de glace carbonique sont-elles réutilisables?

Non. La glace carbonique se sublime complètement, donc les draps sont à usage unique. Si vous avez besoin de solutions réutilisables, choisissez des matériaux à changement de phase ou des packs de gel.

Q3: Comment calculer la quantité de neige carbonique nécessaire?

En règle générale, utiliser 5 à 10 lb (2.3–4,5 kg) de glace sèche par 24 heures d'expédition. Ajuster en fonction du volume d'expédition, qualité de l'isolation et température ambiante.

Q4: Quelles précautions de sécurité dois-je suivre lors de la manipulation de glace carbonique?

Portez toujours des gants et des lunettes isolés; un contact direct avec la peau peut provoquer de graves engelures. Assurer une ventilation adéquate pour éviter l’accumulation de CO₂ et l’asphyxie.

Q5: Les feuilles de glace carbonique peuvent-elles remplacer les packs de gel ou les PCM pour toutes les expéditions?

Non. La glace carbonique fournit des températures ultra froides adaptées aux produits surgelés et aux produits biologiques, mais c'est dangereux et à usage unique. Les packs de gel et les PCM conviennent mieux aux produits réfrigérés et sont réutilisables.

Résumé et recommandations

Les plaques de glace sèche à contrôle de température sont des outils puissants pour la logistique de la chaîne du froid. Ils offrent des températures allant jusqu'à –78,5 °C, fournir de longues durées de refroidissement sans laisser d’humidité, et sont indispensables pour l'expédition des vaccins, produits biologiques et aliments surgelés. Cependant, ils sont à usage unique et classés comme marchandises dangereuses, nécessitant une manipulation minutieuse, ventilation et étiquetage. Des alternatives comme les PCM et les packs de gel sont réutilisables, options non dangereuses pour les expéditions nécessitant des températures plus modérées.

Pour assurer le succès:

Adaptez le réfrigérant à votre produit: Utilisez des feuilles de glace carbonique pour les envois ultra froids et des PCM ou des packs de gel pour les marchandises réfrigérées..

Suivre la réglementation: Se conformer à IATA PI 954, UN1845 et autres règles – ventilation, l'étiquetage et les limites de poids doivent être respectés.

Investissez dans un emballage et un suivi de qualité: Isolation de haute qualité, Les capteurs IoT et les outils logistiques basés sur l'IA améliorent les performances et réduisent les déchets.

Adoptez la durabilité: Adopter des matériaux réutilisables et des emballages biodégradables pour atteindre les objectifs ESG.

Formez votre équipe: Former le personnel à une manipulation sécuritaire, conformité et meilleures pratiques pour minimiser les risques et améliorer l’efficacité.

À propos du tempk

Tempk se spécialise dans les solutions logistiques avancées de la chaîne du froid. Les feuilles de glace carbonique et les dispositifs de surveillance de la température de l'entreprise aident les entreprises à maintenir l'intégrité des expéditions., répondre aux exigences de conformité et réduire l’impact environnemental. En mettant l’accent sur la durabilité et l’innovation, Tempk fournit des conseils personnalisés sur la sélection des bons réfrigérants, méthodes d'emballage et outils de suivi. Si vous êtes prêt à améliorer vos opérations de chaîne du froid, contactez les experts de Tempk pour un accompagnement sur mesure.

Appels à l'action

Consultez un spécialiste de la chaîne du froid: Évaluez vos processus d'expédition actuels et discutez de la manière dont les feuilles de glace carbonique à contrôle de température peuvent améliorer l'efficacité..

Utilisez notre calculateur de glace carbonique: Estimez le nombre de feuilles dont vous avez besoin en fonction du poids de l'envoi, durée et température ambiante.

Répondez au quiz sur la conformité: Testez votre compréhension de PI 954 et les réglementations UN1845 pour vous assurer que vous êtes prêt pour les audits.