Urgent Cold Chain Express Shipping: Stop Excursions?

Urgent cold chain express shipping only works when “fast” is treated as a controlled system, not a faster courier. À ce jour Décembre 18, 2025, les clients attendent de la rapidité et preuve, especially for 2–8°C and frozen lanes. Some industry estimates place the global cold chain market in the hundreds of billions of USD dans 2025, and monitoring markets continue to grow through 2030. Your real enemy is not distance. C'est variabilité—late pack-out, stalled handoffs, and doorstep time.

Cet article répondra pour vous:

-

Comment urgent cold chain express shipping fails (and how you stop it)

-

How to set cut-offs and dwell limits that protect your worst days

-

Comment choisir passive vs active temperature control en anglais simple

-

How to standardize recettes à emporter without overcooling or leaks

-

What monitoring proof works in 2025 (et quand en temps réel pays off)

-

Un outil de décision, ROI check, et rescue ladder you can use today

Why does urgent cold chain express shipping fail when it’s “urgent”?

Urgent cold chain express shipping fails when you compress time and increase handoffs without controlling dwell time. When teams rush, they skip conditioning, stage shipments too long, and accept risky delivery attempts late in the day. Every shortcut burns your thermal budget—the safe time your payload can tolerate outside ideal conditions.

En pratique, most “mystery excursions” happen while a shipment is not moving. It sits on a bench, in a lobby, on a dock, or at a front door. If you control those minutes, reliability rises fast.

The three hidden failure points that burn your thermal budget

| Point de défaillance | Ce qui se passe habituellement | A simple limit you set | Ce que cela signifie pour vous |

|---|---|---|---|

| Staging time | Packed and waiting | 15–30 minutes | Prevents a “warm start” |

| Handoff dwell | Sécurité, cross-dock, queue | 20 minutes per node | Stops silent warming at transitions |

| Doorstep time | Receiver unavailable | 5–10 minutes max | Prevents porch melt and disputes |

Astuces et conseils pratiques

-

Set one clock: seal time starts the thermal budget. Track it every time.

-

Make “waiting” visible: if it can’t be timed, it can’t be improved.

-

Refuse late-day risk: late cut-offs push delivery into the most chaotic hours.

Cas réel: A shipper reduced repeat excursions by enforcing a 20-minute hub dwell rule and a 10-minute doorstep rule. They changed behavior, not coolant volume.

When should you use urgent cold chain express shipping vs standard service?

Use urgent cold chain express shipping when speed reduces exposure risk or prevents a missed window with real consequences. If the consequence is small, “urgent” becomes wasted spend. You want urgency levels that match real risk, not feelings.

This is the simplest way to stop overusing premium service while still protecting critical loads.

Outil de décision interactif: Is your shipment truly urgent?

Notez chaque élément 0–2 (0 = non, 2 = oui). Total 0–10.

-

Fait un 2–4 hour delay trigger reship, rejection, or spoilage?

-

Will the receiver refuse delivery without temperature proof?

-

Is the payload high value per box (a failure hurts)?

-

Y a-t-il un narrow receiving window (clinic, laboratoire, cuisine)?

-

Y a-t-il penalties tied to a time promise?

| Score | Urgency level | Recommended service design | Ce que cela signifie pour vous |

|---|---|---|---|

| 0–3 | Rapide, not urgent | Standard cold chain + tampon | Coût inférieur, fewer exceptions |

| 4–7 | Urgent | Urgent cold chain express shipping + surveillance | Better reliability and proof |

| 8–10 | Critical | 24/7 expédition + escalation + proof on every load | Lowest excursion risk |

Astuces et conseils pratiques

-

If you score 0–3, improve packaging and scheduling before paying urgent fees.

-

If you score 4–7, use urgent service only on lanes that fail often.

-

If you score 8–10, require a written rescue playbook and live escalation.

Cas réel: A clinic labeled everything urgent and costs spiked. After tiering urgency, they protected critical items and reduced late deliveries.

How do you choose passive vs active control for urgent cold chain express shipping?

Your first design choice in urgent cold chain express shipping is passive vs active temperature control. Passive means insulated packaging plus a finite coolant supply. Active means powered refrigeration during transport. Passive scales well when lanes are predictable. Active absorbs chaos better when variability is high.

You do not “graduate” to active because you want to look premium. You upgrade because your lane behaves like a bad day too often.

Plain-English comparison (the version teams actually remember)

-

Passive = “a thermos with smart ice.”

Works when pack-out is repeatable and handoffs are disciplined. -

Active = “a powered fridge on wheels.”

Works when variability is high and failure is expensive.

| Facteur de décision | Passif | Actif | Ce que cela signifie pour vous |

|---|---|---|---|

| Trip variability | Risque moyen | Risque inférieur | Active absorbs chaos |

| Coût par expédition | Inférieur | Plus haut | Passive scales cheaper |

| Setup speed | Fast if standardized | Slower to arrange | Urgent orders need speed |

| Preuve | Strong with loggers | Strong with telemetry | Both can pass audits |

Astuces et conseils pratiques

-

Standardize passive first, then reserve active for the most unstable lanes.

-

If your lane includes de nombreux transferts, treat it like a longer trip.

-

If a single failure is catastrophic, active may be cheaper than losses.

Cas réel: A biotech team moved only “critical-score” shipments to active control. Their overall costs stayed stable while excursions dropped.

How do you set cut-offs and handoff limits for urgent cold chain express shipping?

Cut-offs are the cheapest quality control in urgent cold chain express shipping. A late cut-off forces delivery into traffic peaks, low staffing, and poor receiver coordination. If you promise urgency too late, you create excursions that packaging cannot reliably rescue.

A good cut-off is not based on average transit time. It is based on the worst 20% jour you still want to survive.

A practical cut-off calculator you can use today

Start with promised arrival time, then subtract buffers:

-

Temps de rangement (include conditioning checks)

-

Max staging limit (your rule, not a hope)

-

80th percentile transit time (pas la moyenne)

-

Receiver access buffer (sécurité, elevator, intake)

-

Contingency buffer (météo, surges, ramp delays)

If your remaining time is too small, you move the cut-off earlier or tighten zones.

The “handoff limit rule” (simple, puissant, trainable)

| Node | Maximum dwell | Trigger action | Proof you capture |

|---|---|---|---|

| Warehouse staging | 15–30 minutes | Re-ice / repack / delay release | Temps de scellement + pickup scan |

| Cross-dock / moyeu | 20 min | Reroute / upgrade / cold staging | Hub-in / hub-out scans |

| Seuil de porte | 5–10 minutes | Redirect / retour / staffed desk | Delivery attempt + acceptance time |

Astuces et conseils pratiques

-

Write limits as numbers, not words like “asap.”

-

Escalate early; late escalation is expensive escalation.

-

If receivers are often unavailable, add a backup delivery option.

Cas réel: A food shipper cut refunds after enforcing a hard doorstep limit and redirecting to staffed pickup points.

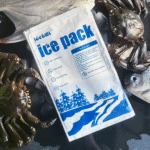

What packaging keeps urgent cold chain express shipping stable on bad days?

Packaging for urgent cold chain express shipping must be designed for exposure time, not transit time. Exposure time includes staging, transferts, and doorstep minutes. The biggest mistake is choosing a shipper based only on “hours in transit.”

Aussi, “colder” is not always better. Overcooling can damage chilled goods just as easily as warming can.

The 4-part pack-out recipe for urgent shipments (repeatable under pressure)

-

Couche d'isolation (controls heat flow and reduces spikes)

-

Stratégie de refroidissement (gel, PCM, or dry ice matched to the band)

-

Protection des produits (séparateurs, doublures, contrôle des fuites, espacement)

-

Verification plan (indicator, enregistreur, or real-time tracker)

Packaging choices that improve outcomes (without false safety)

| Packaging choice | Ce que ça améliore | What it can break | Ce que cela signifie pour vous |

|---|---|---|---|

| More coolant only | Longer cold time | Cold spots, wet boxes | More complaints and rework |

| Meilleure isolation | Slower heat gain | Slightly higher box cost | Fewer excursions and refunds |

| Diviseur + espacement | Fewer cold spots | Extra packing step | More consistent acceptance |

| Seasonal pack-outs | Stability across weather | More SOP discipline | Less “summer chaos” failure |

Astuces et conseils pratiques

-

Prevent freezing: keep coolant off direct contact using a divider layer.

-

Stop heat leaks first: lid fit and seam gaps matter more than “one more pack.”

-

Standardize with photos: one reference photo per lane reduces variation fast.

Cas réel: A pharmacy improved outcomes by upgrading insulation and spacing, not by adding more gel. Weight dropped and hold time improved.

What monitoring proof do you need for urgent cold chain express shipping in 2025?

Dans 2025, urgent cold chain express shipping is shifting to “evidence by default.” Customers want proof, audits expect traceability, and teams need data to improve lanes. But the “best device” is the one you can run consistently.

Start light, run it every time, then upgrade for lanes where intervention is possible.

Choose the lightest tool that still protects you

| Evidence type | Mieux pour | Limitation | Ce que cela signifie pour vous |

|---|---|---|---|

| Temperature indicator | Volume élevé, lower risk | Less precision | Quick acceptance check |

| Trip data logger | Vérifications, réclamations, validation de la voie | Post-trip only | Strong proof after delivery |

| Real-time IoT tracker | Rescue-capable, de grande valeur | Needs response team | Enables mid-route intervention |

A simple rule for when real-time tracking pays off

Use real-time tracking if any is true:

-

One excursion causes full loss (high consequence).

-

Your route delays often, or handoffs are unreliable.

-

You can actually rescue mid-route (reroute, cold stage, meet-and-swap).

-

Disputes require proof within hours, not days.

Astuces et conseils pratiques

-

Pilote d'abord: instrument 10–20 urgent runs per lane before scaling.

-

Define alert thresholds; too many alerts become background noise.

-

Train receivers on a simple acceptance routine to reduce disputes.

Cas réel: A lab used loggers for pilots, then reserved real-time trackers for the highest-risk lanes. Proof improved without runaway costs.

How do you build an exception playbook for urgent cold chain express shipping?

An exception playbook turns urgent cold chain express shipping from improvisation into controlled response. Delays will happen. Your job is to make delays predictable and survivable.

A good playbook answers three questions: Ce qui s'est passé, what do we do now, and what proof do we save?

The R.E.S.C.U.E. one-page script (use it like a fire drill)

| Article | Ce que vous enregistrez | Propriétaire | Ce que cela signifie pour vous |

|---|---|---|---|

| R.oute | Adresses + ETA | Dispatcher | Prevents last-minute confusion |

| Exposure | Max idle minutes | Conducteur | Cuts handoff warming |

| Spec | Bande de température | Expéditeur | Stops “close enough” thinking |

| Chain-of-custody | Seal/pickup/delivery times | Expéditeur + conducteur | Speeds investigations |

| Units | Box count + identifiants | Expéditeur | Prevents missing pieces |

| Escalation | Triggers + contacts | Dispatcher | Turns panic into action |

Rescue ladder (small actions first, bigger actions when needed)

| Rescue level | Trigger example | Action | Ce que cela signifie pour vous |

|---|---|---|---|

| Niveau 1: Reroute | Minor delay | Reorder stops | Saves minutes fast |

| Niveau 2: Redirect | Receiver unavailable | Staffed backup site | Prevents doorstep warming |

| Niveau 3: Re-ice / swap | Major delay risk | Meet-and-swap coolant/box | Buys temperature time |

| Niveau 4: Abort safely | Range at risk | Return to hub | Prevents unsafe delivery |

Astuces et conseils pratiques

-

Pre-approve backup locations; don’t negotiate during the incident.

-

Keep a rescue kit ready: spare coolant, ruban adhésif, étiquettes, séparateurs.

-

Use one escalation phone tree so no one searches contacts under pressure.

Cas réel: A shipper added meet-and-swap for stalled routes. A second driver delivered fresh coolant and saved critical loads.

What does a good SLA look like for urgent cold chain express shipping?

A good SLA for urgent cold chain express shipping measures speed and quality together. If you only measure “delivered fast,” you will deliver fast failures. SLAs should include time, température, preuve, and exception rules.

SLA metrics that improve outcomes

| SLA metric | Que suivre | Target style | Pourquoi ça compte |

|---|---|---|---|

| Livraison à temps | % within promise | Haut | Confiance du client |

| Tarif excursion | % out of range | Faible | Direct quality signal |

| Dwell compliance | % within limits | Haut | Controls handoff risk |

| Exception closure time | Minutes to resolve | Faible | Prevents repeat failures |

| Proof completeness | % with usable proof | Haut | Audits et litiges plus rapides |

Calculateur de retour sur investissement (quick, usable, honest)

Remplissez vos numéros:

-

Average gross margin per shipment: ____

-

Average reship/refund cost when compromised: ____

-

Current compromise rate: ____%

-

Target compromise rate: ____%

-

Incremental urgent service cost (par 100 expéditions): ____

Expected savings per 100 shipments =(Current rate − Target rate) × (Reship/refund cost) × 100

If expected savings exceed incremental cost, urgent upgrades are financially justified.

2025 latest developments and trends in urgent cold chain express shipping

Dans 2025, urgent cold chain express shipping is becoming more standardized and less improvisational. More teams are building ready kits for rapid pack-out. More buyers expect evidence, not reassurance. Monitoring and visibility are expanding, and many shippers are treating temperature excursions like incident response with clear ownership.

Dernier aperçu des progrès

-

Lane standardization rises: fewer one-off pack-outs, more repeatable recipes.

-

Proof becomes normal: monitoring plans are moving from optional to expected.

-

Escalation loops tighten: teams intervene earlier, not after complaints arrive.

-

“Rescue-ready” becomes a premium tier: not every urgent lane needs rescue capability.

Perspicacité du marché: urgent programs scale best where failure is costly—high-value perishables, Soins de santé, and premium customer promises.

Questions courantes (FAQ)

Q1: When should you use urgent cold chain express shipping instead of standard service?

Use it when speed reduces exposure risk or prevents a missed receiving window with real consequences. If failure cost is high, urgency is justified.

Q2: Do you always need real-time temperature tracking for urgent shipments?

Non. Many lanes succeed with trip loggers and strict dwell limits. Use real-time tracking when you can rescue mid-route.

Q3: What is the biggest cause of excursions in urgent cold chain express shipping?

Uncontrolled dwell time—staging, transferts, or doorstep waiting. Control those minutes and reliability rises quickly.

Q4: How do you prevent chilled products from freezing in urgent shipping?

Évitez tout contact direct avec le liquide de refroidissement. Use divider layers, espacement, and consistent layouts that prevent cold spots.

Q5: How much buffer should packaging provide for urgent cold chain express shipping?

Cover planned time plus realistic delay. Design for “normal chaos,” not perfect days.

Q6: What should an SLA include for urgent cold chain express shipping?

Include the deadline time, bande de température, proof method, dwell limits, and exception actions. Clarity prevents disputes.

Résumé et recommandations

Urgent cold chain express shipping succeeds when you control variability, not when you chase speed alone. Set cut-offs that protect your worst days. Enforce hard limits for staging, transferts, and doorstep time. Standardize one pack-out recipe per lane and temperature band. Add monitoring proof that matches risk, and run an exception playbook that triggers action fast.

Votre prochaine étape (CTA)

Prendre une voie and complete this 2-week upgrade:

-

Set three limits (mise en scène, hub dwell, doorstep).

-

Standardiser one pack-out recipe and photo reference.

-

Add proof (logger or real-time) based on your urgency score.

-

Review every exception weekly and fix one root cause each week.

À propos du tempk

Et tempk, we help teams build urgent cold chain express shipping workflows that stay stable under real-world delays. We focus on lane design, repeatable pack-out systems, monitoring plans that produce usable evidence, and rescue playbooks your team will actually follow. We avoid over-complication and prioritize controls that reduce excursions, litiges, and costly reships.

Appel à l'action: Share your temperature band, worst-day transit time, and handoff map. We’ll outline a lane blueprint and a validation checklist you can operationalize quickly.