Qu'est-ce que l'expédition sous chaîne du froid et comment ça marche?

Mis à jour: Novembre 14, 2025

Expédition de chaîne de froid protège les marchandises sensibles à la température de la détérioration en maintenant des plages de température strictes pendant le stockage et le transport. Ce processus préserve l'intégrité des produits comme les vaccins, produits frais et surgelés, préserver la santé publique et réduire les déchets. En combinant la réfrigération, isolation et surveillance en temps réel, l'expédition sous chaîne du froid garantit que les produits arrivent dans des conditions optimales, même sur des distances mondiales.

La définition et le processus du transport sous chaîne du froid, y compris les étapes clés et l'équipement

Les industries et les produits qui dépendent de la logistique sous chaîne du froid et leurs besoins spécifiques

Défis courants tels que le contrôle de la température, visibilité et conformité réglementaire

Solutions innovantes et meilleures pratiques pour maintenir l’intégrité des produits

Tendances émergentes qui façonnent le transport sous chaîne du froid 2025 et au-delà

Comment fonctionne l'expédition sous la chaîne du froid?

L'expédition sous chaîne du froid est un processus logistique spécialisé qui maintient les produits dans des plages de température définies depuis l'origine jusqu'à la livraison.. Cela implique une série d’étapes soigneusement contrôlées, en commençant par un emballage approprié, se poursuivant grâce au stockage et au transport à température régulée, et se terminant par une livraison vérifiée. Chaque phase utilise des équipements et des protocoles dédiés pour éviter les excursions de température susceptibles de dégrader la qualité.. Étant donné que la sensibilité à la température varie (des produits laitiers réfrigérés aux vaccins ultra froids), les opérateurs sélectionnent la bonne combinaison d'unités de réfrigération., conteneurs isothermes et systèmes de surveillance adaptés aux besoins du produit.

Le maintien d’une chaîne du froid continue nécessite une coordination entre les producteurs, transporteurs, exploitants d'entrepôts et détaillants. D'abord, les produits sont emballés dans des conteneurs isothermes avec des agents réfrigérants tels que des packs de gel, glace carbonique ou matériaux à changement de phase. Ils entrent ensuite dans des entrepôts frigorifiques équipés de surgélateurs., zones multi-températures et portes hermétiques pour minimiser le transfert de chaleur. Pendant le transport, camions frigorifiques, les conteneurs ou les unités de fret aérien maintiennent la plage de température requise. Capteurs et Internet des objets (IoT) les appareils surveillent la température, humidité et vibrations, envoyer des alertes en temps réel si les conditions s'écartent. À l'arrivée, les équipes de réception vérifient les enregistrements de température et complètent la documentation pour confirmer la conformité.

Le transport moderne sous chaîne du froid utilise l'IoT avancé et l'analyse des données pour optimiser les itinéraires et prédire les pannes d'équipement.. Selon les experts du secteur, l’adoption de la technologie s’accélère, et les capteurs offrent désormais une visibilité en temps réel sur l'état de la cargaison. Les outils d'analyse prédictive combinent les données historiques de température avec des variables externes, comme la météo, anticiper et prévenir les écarts de température. Ces innovations permettent aux entreprises de résoudre les problèmes de manière proactive, réduire la détérioration et garantir le respect de réglementations strictes.

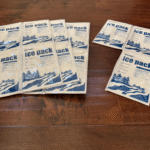

Solutions d'emballage à température contrôlée

L’emballage est la première ligne de défense dans le transport sous chaîne du froid. Boîtes isolées, les sacs et doublures thermiques créent des barrières contre les fluctuations de température externes. Les packs de gel et la glace carbonique assurent un refroidissement actif, tandis que les panneaux à vide haute performance (Vips) et les matériaux à changement de phase prolongent les temps de maintien. Ces solutions doivent équilibrer l'isolation, poids et coût, en particulier pour les livraisons du dernier kilomètre où l'exposition aux températures ambiantes est la plus grande. Le choix de l’emballage approprié dépend des exigences de température du produit, durée d’expédition et contraintes réglementaires. Par exemple, les produits pharmaceutiques utilisent souvent des conteneurs isolés sous vide avec des enregistreurs de données intégrés pour garantir la traçabilité, considérant que les livraisons de kits repas peuvent reposer sur des doublures isolées et des packs de gel pour le transport sur de courtes distances.

| Type d'emballage | Niveau d'isolation | Réutilisabilité | Avantage pratique |

| Packs de gel & doublures isolantes | Modéré | Réutilisable | Convient aux livraisons courtes; facile à emballer et à jeter |

| Panneaux isolés sous vide (Vips) | Haut | Réutilisation limitée en raison du coût | Maintenir les températures pendant de longues durées; idéal pour les produits pharmaceutiques |

| Matériaux à changement de phase | Haut | Réutilisable | Fournit une température constante sans glace carbonique; réduire le risque de gel |

| Glace carbonique dans des conteneurs isothermes | Très élevé | Usage unique | Atteint des températures ultra basses pour les vaccins et les produits biologiques |

Conseils pratiques pour l’emballage sous chaîne du froid

Pour les livraisons courtes: Utilisez des packs de gel avec des doublures isolées et assurez une manipulation minimale entre le stockage et la livraison..

Pour les produits ultra froids: Choisissez de la neige carbonique ou des matériaux à changement de phase spécialisés adaptés à la plage de température du produit..

Pour la durabilité: Optez pour des sacs thermiques ou des panneaux sous vide réutilisables lorsque cela est possible et mettez en place un programme de retour.

Exemple du monde réel: Pendant la pandémie de COVID 19, les fabricants de vaccins ont expédié des doses dans des conteneurs équipés de capteurs de température en temps réel et de matériaux à changement de phase. Ces conteneurs maintenaient des températures ultra basses jusqu'à 10 jours, permettant une distribution mondiale sûre.

Quels composants et industries dépendent du transport sous chaîne du froid?

L'expédition sous chaîne du froid dépend d'un réseau de composants spécialisés qui travaillent ensemble pour préserver l'intégrité du produit.. Ces composants comprennent un stockage à température contrôlée, matériel de transport, systèmes de surveillance et personnel formé. Comprendre comment ces éléments interagissent aide les entreprises à sélectionner les bons partenaires et à éviter les pertes de produits.. Des industries allant de l'alimentation et de la santé à la chimie et aux cosmétiques s'appuient sur la logistique de la chaîne du froid pour répondre aux normes de sécurité et aux attentes des consommateurs..

L’épine dorsale du transport sous chaîne du froid est constituée d’entrepôts réfrigérés, camions frigorifiques, unités de fret aérien et emballages isothermes. Les installations de stockage frigorifique utilisent des surgélateurs, zones réfrigérées et contrôle de l’humidité pour préserver les matières premières et les produits finis. Pendant le transport, les conteneurs frigorifiques et les camions maintiennent des plages de température spécifiques, souvent géré par des thermostats automatisés et des systèmes télématiques qui ajustent les niveaux de réfrigération en fonction des conditions ambiantes. Les systèmes de surveillance en temps réel suivent l'emplacement, température et humidité, fournir des alertes lorsque des écarts se produisent et offrir une preuve de conformité.

De nombreuses industries dépendent de la logistique de la chaîne du froid. Le secteur alimentaire l'utilise pour maintenir la fraîcheur et la sécurité, réduire les milliards de dollars de pertes alimentaires annuelles. Les soins de santé et les produits pharmaceutiques exigent de la précision dans la manipulation des vaccins, produits biologiques et médicaments sensibles à la température; même une brève exposition à des températures incorrectes peut rendre les expéditions inutilisables. D'autres secteurs incluent les produits chimiques, produits de beauté, et horticulture, qui exigent tous un contrôle strict de la température et une documentation solide.

Un rapport de MarketsandMarkets prévoit que le marché mondial de la surveillance de la chaîne du froid atteindra le dollar américain. 17.8 milliards 2025. Cette croissance reflète la demande croissante de produits périssables et l'augmentation des investissements dans les technologies de surveillance.. Alors que le commerce mondial se développe, ces composants et industries continueront d’évoluer, mettant l’accent sur la résilience et la visibilité en temps réel.

Industries dépendantes du transport sous chaîne du froid

Différentes industries ont des exigences uniques en matière d’expédition sous chaîne du froid:

Nourriture et boisson: Aliments périssables comme la viande, laitier, les fruits et légumes nécessitent des plages de température strictes pour éviter leur détérioration. La logistique de la chaîne du froid prolonge la durée de conservation et réduit les déchets, économiser des milliards chaque année.

Pharmaceutique et biotechnologie: Vaccins, l'insuline et les produits biologiques exigent des conditions extrêmement froides et une traçabilité rigoureuse pour garantir leur efficacité. Les écarts de température peuvent entraîner des rappels de produits et de graves conséquences sur la santé.

Produits chimiques et matériaux industriels: Certains produits chimiques et adhésifs doivent être conservés dans des plages de température spécifiques pour conserver leurs propriétés.. Ne pas le faire peut entraîner des réactions dangereuses ou une défaillance du produit..

Cosmétiques et soins personnels: De nombreux cosmétiques contiennent des huiles naturelles et des ingrédients sensibles à la chaleur. Un contrôle approprié de la température empêche la séparation, décoloration et dégradation.

Horticulture et floriculture: Les fleurs et les plantes vivantes nécessitent des climats contrôlés pendant le transport pour conserver leur fraîcheur et leur qualité..

| Composant | But | Industries desservies | Ce que cela signifie pour vous |

| Entrepôt frigorifique | Maintient des températures constantes grâce aux surgélateurs et au contrôle de l'humidité. | Nourriture, médicaments, produits chimiques | Protège les stocks pendant la production et la préparation |

| Camions frigorifiques et conteneurs | Transporter des marchandises dans des plages de température contrôlées | Nourriture, Pharma, horticulture, produits chimiques | Permet une expédition longue distance sans détérioration |

| Systèmes de surveillance IoT | Fournir des données en temps réel sur la température, humidité et emplacement | Toutes les industries de la chaîne du froid | Offre transparence et alertes immédiates pour éviter la perte de produit |

| Personnel qualifié et SOP | Assurer une bonne manipulation, documentation et conformité réglementaire | Sécurité alimentaire, Soins de santé, matières dangereuses | Réduit les erreurs humaines et répond à des réglementations strictes |

Comment choisir le bon partenaire de la chaîne du froid

Vérifier l’expertise du secteur: Assurez-vous que votre prestataire logistique a de l'expérience avec votre catégorie de produits spécifique et comprend les réglementations pertinentes..

Vérifier les capacités technologiques: Recherchez des fournisseurs offrant une surveillance en temps réel, analyses prédictives et rapports automatisés.

Évaluer les infrastructures: Évaluer l’état et l’emplacement des entrepôts, véhicules frigorifiques et options de livraison du dernier kilomètre.

Cas pratique: Un important exportateur de produits de la mer s'est associé à un prestataire logistique spécialisé dans le transport à ultra basse température. En intégrant des capteurs en temps réel et des analyses prédictives, l'exportateur a réduit les taux de détérioration de 30% et durée de conservation prolongée, conduisant à des bénéfices plus élevés et à une meilleure satisfaction des clients.

À quels défis le transport sous chaîne du froid est-il confronté?

Le transport sous chaîne du froid est confronté à de nombreux défis qui peuvent compromettre la qualité des produits et augmenter les coûts.. Ces défis incluent le maintien de plages de température précises, assurer une visibilité en temps réel tout au long de la chaîne d’approvisionnement, respecter les exigences réglementaires et gérer des coûts opérationnels élevés. Reconnaître ces obstacles aide les entreprises à concevoir des stratégies pour atténuer les risques et protéger leurs marchandises..

Le maintien de conditions environnementales précises est l’un des plus grands défis du transport maritime sous chaîne du froid.. Les écarts de température et d’humidité pendant le chargement ou le transport peuvent gâcher les vaccins, aliments ou produits chimiques, entraînant des pertes coûteuses ou des risques pour la santé. La visibilité en temps réel reste limitée dans de nombreuses opérations car les expéditions reposent sur des journaux manuels ou des contrôles peu fréquents, transformer les marchandises en « boîtes noires ». La conformité réglementaire ajoute un autre niveau de complexité; les produits pharmaceutiques et les aliments de grande valeur nécessitent une documentation exhaustive et des pistes d'audit inviolables dans différentes régions.

Les contraintes d’infrastructure mettent également à rude épreuve la chaîne du froid. L’urbanisation rapide et la demande croissante dépassent souvent le développement des entrepôts réfrigérés et des véhicules de transport., créer des pénuries de capacités. La hausse des coûts de l’énergie et les suppléments carburant augmentent les dépenses d’exploitation, et les équipements spécialisés comme les camions réfrigérés et les congélateurs nécessitent un investissement en capital important.. Le dernier kilomètre est particulièrement difficile, car les livraisons doivent naviguer dans le trafic urbain ou dans des endroits éloignés tout en maintenant le contrôle de la température. La surcharge de données et les problèmes d’intégration du système compliquent encore les choses: les entreprises utilisent plusieurs dispositifs et plates-formes de surveillance, ce qui rend difficile l'obtention d'informations exploitables ou le partage d'informations de manière transparente.

Les fluctuations saisonnières de la demande et les exigences de stockage à plusieurs températures ajoutent de la variabilité, tandis que la logistique fragmentée réduit la responsabilité et augmente le risque de mauvaise manipulation. Selon une étude de l'Université Cornell, L'optimisation du contrôle de la température dans les camions réfrigérés grâce à des techniques de planification avancées peut réduire la consommation de carburant jusqu'à 40%. Cette découverte souligne l’importance de l’amélioration de la technologie et des processus pour surmonter les défis..

Principaux points sensibles du transport sous chaîne du froid

Les points douloureux courants incluent:

Contrôle précis de la température: Même de courtes excursions peuvent gâcher les marchandises ou rendre les vaccins inefficaces.

Manque de visibilité en temps réel: Sans surveillance constante, les managers peuvent être informés des problèmes seulement après qu'ils se soient produits.

Conformité réglementaire: Des exigences strictes en matière de documentation augmentent la charge de travail et le risque d'erreur.

Pénurie d’infrastructures: La capacité limitée des entrepôts frigorifiques et les véhicules frigorifiques entraînent des retards et des détériorations..

Hausse des coûts et efficacité énergétique: Les équipements spécialisés et les prix fluctuants des carburants exercent une pression sur les marges.

Livraison complexe du dernier kilomètre: Coordonner les livraisons dans des zones urbaines denses ou des régions éloignées tout en maintenant la température est un défi.

Surcharge de données et intégration: Plusieurs systèmes de surveillance créent des silos de données qui limitent les informations exploitables.

Préoccupations en matière de durabilité: Les clients et les régulateurs exigent des pratiques plus écologiques, mais les entreprises s'inquiètent des coûts.

| Défi | Impact sur la chaîne d'approvisionnement | Pourquoi ça compte pour toi |

| Excursions de température | Provoque une détérioration du produit et des risques pour la santé | Entraîne des pertes financières, rappels et atteinte à la réputation |

| Visibilité limitée | Retards dans l’identification des problèmes | Empêche les interventions proactives et les rapports de conformité |

| Complexité de la conformité | Nécessite une documentation et des audits détaillés | Augmente les coûts administratifs et les pénalités potentielles |

| Lacunes en matière d’infrastructures | Stockage frigorifique et capacité des véhicules insuffisants | Limite la croissance et l’évolutivité |

| Coûts énergétiques élevés | Augmente les dépenses de fonctionnement | Pressions sur les marges bénéficiaires et les efforts de développement durable |

| Risques du dernier kilomètre | Augmente le risque de rupture de température | Menace la satisfaction des clients et la confiance dans la marque |

| Fragmentation des données | Crée des silos d’informations et des retards | Entrave la prise de décision et l’amélioration continue |

Stratégies pour atténuer les défis de la chaîne du froid

Investissez dans la surveillance en temps réel: Utiliser des capteurs, Appareils GPS et IoT pour suivre la température et la localisation en continu.

Élaborer des plans d’urgence: Préparer des options de réfrigération de secours et des itinéraires alternatifs en cas de retards imprévus.

Former le personnel: Former le personnel aux procédures de contrôle de la température, exigences en matière de documentation et de réglementation.

Collaborer avec des partenaires: Partager des données entre fournisseurs, transporteurs et clients pour améliorer la visibilité et la responsabilité.

Étude de cas: Un expéditeur de produits pharmaceutiques a mis en œuvre une plateforme de surveillance intégrée tout au long de sa chaîne d'approvisionnement. Des alertes en temps réel ont permis des actions correctives immédiates, réduisant les écarts de température en 60% et éliminer les rappels de produits coûteux.

Quelles solutions et bonnes pratiques améliorent l'expédition sous la chaîne du froid?

Pour surmonter ces défis, les entreprises déploient une combinaison de technologies, améliorations des processus et formation. Surveillance en temps réel, analyse prédictive, l'automatisation et l'emballage optimisé jouent tous un rôle dans la protection des marchandises sensibles à la température. En adoptant les meilleures pratiques, les entreprises peuvent réduire leurs déchets, améliorer la satisfaction client et respecter les normes réglementaires.

La mise en œuvre de dispositifs de surveillance connectés est l'un des moyens les plus efficaces d'améliorer la visibilité et le contrôle environnemental.. Les trackers multi-capteurs fournissent une localisation GPS en temps réel et mesurent la température et l'humidité., envoi d'alertes instantanées si les lectures dérivent en dehors des limites prédéfinies. Ces appareils stockent également des milliers d'enregistrements de données pour conserver une piste d'audit complète en cas de panne de réseau.. Déploiement sur palettes, les conteneurs ou les véhicules offrent aux entreprises une visibilité de bout en bout et leur permettent d'intervenir rapidement pour ajuster les conditions ou réacheminer les expéditions avant que la détérioration ne se produise.. Les applications mobiles et les plateformes cloud permettent aux opérateurs et aux clients de surveiller l'état des expéditions depuis n'importe où., instaurer la confiance et faciliter la conformité réglementaire.

L'analyse des données et la gestion prédictive transforment les données historiques en informations exploitables. Les outils prédictifs combinent les enregistrements de température avec des facteurs externes tels que les prévisions météorologiques et les données de performances des véhicules pour anticiper les problèmes potentiels.. Par exemple, si un itinéraire particulier en été fait généralement travailler plus fort les unités de réfrigération, les planificateurs peuvent sélectionner des itinéraires alternatifs ou améliorer l'isolation pour cette étape. L'intégration des données des capteurs aux systèmes de gestion d'entrepôt prend en charge le contrôle dynamique des stocks: si un tracker IoT indique une hausse des températures dans une chambre froide, les opérateurs peuvent réacheminer les marchandises vers un autre stockage ou augmenter la puissance de refroidissement. Les algorithmes d'apprentissage automatique aident à identifier les expéditions qui présentent le plus grand risque de retard ou de détérioration., permettant une surveillance ciblée et une maintenance préventive.

L'automatisation et l'optimisation des processus réduisent les erreurs humaines et améliorent l'efficacité. Systèmes automatisés de stockage et de récupération, les systèmes de convoyeurs numériques et les quais de chargement automatisés maintiennent des températures constantes et accélèrent les opérations. Systèmes de gestion des transports (TMS) automatisez les flux de travail d'alerte afin que les alertes déclenchent des notifications au personnel concerné par SMS ou par e-mail. Certains opérateurs de la chaîne du froid expérimentent des véhicules à guidage automatique (AGV) et des drones pour la livraison du dernier kilomètre, qui promettent des temps de transit plus rapides et une exposition réduite à la chaleur.

Les mesures de contrôle des coûts se concentrent sur l’optimisation des itinéraires, améliorer l'économie de carburant et augmenter l'efficacité énergétique. Les systèmes télématiques analysent les données de trafic en temps réel pour minimiser la marche au ralenti, réduisant la consommation de carburant et les fluctuations de température. Moderniser les entrepôts avec un éclairage LED, des compresseurs à vitesse variable et une meilleure isolation peuvent réduire considérablement la consommation d'électricité. Certaines entreprises adoptent des panneaux solaires ou des programmes d'énergie verte pour compenser les coûts et la production de carbone, tandis que les innovations en matière d'emballage telles que les couvertures isolantes haute performance et les packs de gel à changement de phase aident à maintenir les températures plus longtemps et à réduire les pertes.. Formation du personnel, les contrôles de routine des équipements et les procédures de chargement strictes contribuent également à des températures constantes et à une réduction des déchets.

Solutions innovantes pour le transport sous chaîne du froid

Les innovations clés incluent:

Dispositifs de suivi IoT: Les trackers multi-capteurs fournissent des données de température et de localisation en temps réel, permettant une intervention proactive et des rapports automatisés.

Analyse prédictive: Les plateformes d'analyse utilisent des données historiques et des variables externes pour prévoir les pannes potentielles et optimiser les itinéraires..

Automation: Systèmes de stockage automatisés, Les TMS et les AGV réduisent la manipulation manuelle et maintiennent la cohérence de la température.

Emballage intelligent: Couvertures isolantes haute performance, les panneaux sous vide et les matériaux à changement de phase étendent le contrôle de la température tout en réduisant le poids et les déchets.

Énergie durable: Les panneaux solaires et les systèmes de réfrigération économes en énergie réduisent les coûts d'exploitation et les émissions de carbone.

| Solution | Description | Avantages |

| Capteurs et trackers IoT | Appareils qui mesurent la température, humidité et localisation en temps réel | Améliorer la visibilité, éviter la détérioration et automatiser la conformité |

| Logiciel d'analyse prédictive | Utilise des données historiques pour prévoir les excursions potentielles de température et les pannes d'équipement | Prend en charge la maintenance préventive et l’optimisation des itinéraires |

| Stockage et récupération automatisés | Robotique et AGV pour manipuler les marchandises avec un minimum de contact humain | Réduire les erreurs de manipulation et maintenir des températures stables |

| Emballage haute performance | Vips, matériaux à changement de phase et couvertures isolantes | Prolongez la durée de refroidissement et réduisez les déchets |

| Investissements dans les énergies renouvelables | Panneaux solaires, Éclairage LED et compresseurs efficaces | Réduire les coûts d’exploitation et l’empreinte carbone |

Meilleures pratiques pour une expédition fiable sous la chaîne du froid

Mettre en œuvre une surveillance de bout en bout: Équipez chaque palette ou conteneur de capteurs et intégrez les données dans un tableau de bord unifié.

Utiliser les données pour prendre des décisions: Tirer parti des analyses pour planifier des itinéraires, planifier la maintenance et sélectionner l’emballage approprié.

Privilégier l'automatisation: Adopter des systèmes automatisés de chargement, stockage et documentation pour minimiser les erreurs humaines.

Investissez dans la technologie durable: Explorez les sources d'énergie renouvelables et les réfrigérants écologiques pour réduire les coûts et l'impact environnemental.

Exemple: Un service leader de livraison d'épicerie investi dans la télématique et des panneaux solaires pour ses centres de distribution. En optimisant la planification des itinéraires et en réduisant la consommation électrique, l'entreprise a réduit ses coûts énergétiques de 25% tout en améliorant les délais de livraison.

2025 Derniers développements et tendances en matière de transport sous chaîne du froid

L'industrie de la chaîne du froid évolue rapidement, et 2025 apporte une gamme de nouvelles tendances et innovations. Croissance du marché mondial, l'adoption de technologies et les initiatives en matière de développement durable remodèlent la façon dont les marchandises sensibles à la température sont expédiées. Rester informé de ces évolutions aide les entreprises à rester compétitives et réactives aux demandes changeantes des consommateurs..

La croissance du marché reste forte. Dans 2023 le marché mondial de la logistique de la chaîne du froid était évalué à USD 293.58 milliards et devrait croître de USD 324.85 milliards en 2024 en USD 862.33 milliards 2032, représentant un taux de croissance annuel composé (TCAC) de 13%. Cette expansion est motivée par la demande croissante de produits frais, protéines végétales et produits pharmaceutiques sensibles à la température. Les aliments d’origine végétale pourraient à eux seuls représenter 7.7% du marché mondial des protéines, évalué à plus de USD 162 milliards 2030. Le secteur pharmaceutique est également en expansion, avec des revenus qui devraient croître à un TCAC de 4.71% depuis 2024 à 2029.

Les nouvelles tendances technologiques incluent un investissement accru dans les logiciels de visibilité de la chaîne d'approvisionnement et les outils de surveillance en temps réel.. Les entreprises déploient des capteurs avancés, les systèmes blockchain et les plateformes permettant à l'IA d'obtenir des données ininterrompues tout au long de la chaîne du froid. La modernisation des installations de stockage frigorifique est un autre domaine d’intérêt; les infrastructures vieillissantes construites il y a 40 à 50 ans sont remplacées par des infrastructures automatisées, entrepôts économes en énergie. Les réglementations environnementales conduisent à l’élimination progressive des réfrigérants synthétiques, inciter à investir dans des réfrigérants naturels et des systèmes économes en énergie. Des réseaux de distribution améliorés émergent, avec des installations plus grandes et des emplacements centrés sur les ports, conçus pour accueillir des volumes commerciaux croissants et assurer une livraison plus rapide du dernier kilomètre.

Les acteurs du secteur s'attendent à une visibilité et une résilience accrues grâce à des partenariats logistiques intégrés. Faire face aux perturbations géopolitiques et à la volatilité des marchés, les entreprises se concentrent sur des partenariats offrant une intégration complète de la chaîne d’approvisionnement et une capacité fiable. Alors que de plus en plus de petites et moyennes entreprises entrent sur le marché de la chaîne du froid, il existe une demande croissante de prestataires logistiques experts capables de gérer des exigences complexes et de faire évoluer les opérations.

Dernières innovations en matière d’expédition sous chaîne du froid

Tendances clés pour 2025 inclure:

Résilience et croissance du marché: Malgré les perturbations géopolitiques, le marché de la chaîne du froid reste stable en raison de la forte demande en produits alimentaires et pharmaceutiques. Les entreprises investissent dans des installations de stockage frigorifique plus grandes et dans des réseaux intégrés.

Visibilité améliorée: L'investissement continu dans les logiciels et les appareils IoT fournit des données ininterrompues et un meilleur suivi de localisation.

Nouvelles catégories de produits: Les protéines végétales et les aliments de spécialité nécessitent un contrôle précis de la température, proposer des solutions logistiques personnalisées.

Modernisation des infrastructures: Les anciennes installations de stockage frigorifique sont modernisées grâce à l'automatisation, systèmes d’énergie renouvelable et réfrigérants conformes.

Partenariats stratégiques: Les entreprises multiplient les collaborations avec les prestataires logistiques pour gagner en résilience et en capacité sur des marchés volatils.

| S'orienter | Description | Implication |

| Croissance et diversification du marché | Augmentation de la valeur marchande tirée par la demande alimentaire et pharmaceutique | Plus d'opportunités pour les nouveaux entrants et les services spécialisés |

| Visibilité de la chaîne d'approvisionnement | Investissement dans l'IoT, blockchain et plateformes logicielles pour une surveillance continue | Conformité améliorée, réduction de la détérioration et amélioration de la confiance |

| Modernisation des infrastructures | Modernisation des installations vieillissantes avec automatisation et réfrigérants naturels | Efficacité accrue et impact environnemental réduit |

| Pratiques durables | Adoption d’emballages respectueux de l’environnement et d’énergies renouvelables | S'aligne sur les attentes des clients et les exigences réglementaires |

| Partenariat et intégration | Collaboration entre chargeurs, opérateurs et fournisseurs de technologie | Renforce la résilience et l’évolutivité |

Garder une longueur d'avance 2025 Tendances de la chaîne du froid

Adopter des outils de visibilité: Investissez dans des plateformes de surveillance de bout en bout intégrant des capteurs, analyse et blockchain.

Mettre à jour l'infrastructure: Planifier la mise à niveau des équipements d'entreposage frigorifique et de transport pour se conformer aux nouvelles réglementations sur les réfrigérants.

Diversifier les offres: Envisagez des produits à base de plantes et spécialisés qui nécessitent des solutions de chaîne du froid sur mesure.

Renforcer les partenariats: Travailler avec des prestataires de logistique intégrée qui peuvent offrir une résilience lors de perturbations géopolitiques.

Aperçu: Selon Maersk 2025 rapport de tendances, le marché de la logistique de la chaîne du froid se prépare aux perturbations à venir grâce à des investissements en visibilité et en capacité.

Questions fréquemment posées

Quelle est la différence entre l’expédition sous chaîne du froid et l’expédition régulière?

L’expédition sous chaîne du froid implique le maintien d’un contrôle strict de la température tout au long du stockage et du transport., alors que le transport régulier ne nécessite pas de régulation de la température. Le transport sous chaîne du froid utilise des équipements spécialisés, systèmes de surveillance et documentation pour assurer la sécurité et la conformité des produits.

Pourquoi le transport sous chaîne du froid est-il important pour les vaccins?

Les vaccins sont sensibles aux variations de température; même une brève exposition à la chaleur peut les rendre inefficaces. L'expédition sous chaîne du froid garantit que les vaccins restent dans des plages de températures ultra basses, de la fabrication à l'administration..

Comment les entreprises peuvent-elles réduire les coûts d’expédition sous la chaîne du froid ??

Les entreprises peuvent optimiser les itinéraires grâce à la télématique, mise à niveau vers une réfrigération économe en énergie, et investissez dans l’analyse prédictive pour éviter le gaspillage. La sélection du personnel d'emballage et de formation approprié permet également de contrôler les coûts..

Quelles réglementations s’appliquent au transport sous chaîne du froid?

Les réglementations varient selon la région et le produit, mais incluent généralement des directives d'agences comme la FDA., PIB de l’OMS et de l’UE. Ces règles nécessitent des enregistrements de température détaillés, équipement validé et respect des bonnes pratiques de distribution.

Quel rôle joue la technologie dans le transport sous chaîne du froid ??

La technologie permet une surveillance en temps réel, analyse prédictive, automatisation et intégration de données, permettant des interventions proactives et une meilleure conformité.

Résumé et recommandations

L'expédition sous chaîne du froid est un processus logistique spécialisé qui maintient un contrôle strict de la température depuis la production jusqu'à la livraison.. Il s'appuie sur des emballages isothermes, stockage et transport réfrigérés, Surveillance de l'IoT et personnel formé pour protéger les marchandises périssables et les produits pharmaceutiques. Les principaux défis incluent les excursions de température, visibilité limitée, complexités de conformité et coûts énergétiques élevés. Pour surmonter ces défis, les entreprises devraient investir dans des capteurs en temps réel, analyse prédictive, automatisation et infrastructure économe en énergie. L'adoption de ces solutions améliore la qualité des produits, réduit les déchets et prépare les entreprises à la croissance rapide et à l’innovation attendues dans 2025.

Pour démarrer avec une expédition fiable sous chaîne du froid:

Évaluez vos processus actuels: Identifier les lacunes dans la surveillance de la température, capacité de documentation et de stockage.

Investir dans la technologie: Équipez les expéditions de capteurs IoT et adoptez des plateformes d’analyse pour prévoir les risques.

Formez votre équipe: S'assurer que le personnel comprend les procédures de manipulation, exigences réglementaires et protocoles d’urgence.

Partenaire stratégique: Travailler avec des prestataires logistiques intégrés qui proposent des solutions complètes de chaîne du froid.

Planifier pour la durabilité: Améliorer les installations avec une réfrigération économe en énergie et explorer les emballages réutilisables.

Prêt à renforcer votre chaîne du froid? Contactez-nous dès aujourd'hui pour discuter de solutions sur mesure qui protègent vos produits et soutiennent la croissance de votre entreprise..

À propos du tempk

Tempk est un fournisseur mondial de solutions innovantes pour la chaîne du froid. Nous sommes spécialisés dans les emballages isothermes, des conteneurs à température contrôlée et des systèmes de surveillance en temps réel qui aident les entreprises à préserver l'intégrité des produits. Notre équipe combine des décennies d'expérience avec une technologie de pointe pour fournir des, des services de chaîne du froid efficaces et durables. Nous sommes fiers de notre engagement envers la qualité et de notre capacité à adapter des solutions à diverses industries, de l'alimentation et des produits pharmaceutiques aux produits chimiques et cosmétiques.. Avec Tempk comme partenaire, vous accédez à un réseau d'experts dédiés à la protection de vos produits et à l'accompagnement de votre croissance.

Appel à l'action: Consultez nos experts dès aujourd’hui pour concevoir une stratégie de chaîne du froid qui répond à vos besoins spécifiques et à vos exigences de conformité.