DryIcePackTemperature Mastery: Der 2025 Cold‑Chain Playbook

Aufrechterhaltung der ideal dry ice pack temperature of –78 °C (–109°F) ist nicht länger optional – es ist der Dreh- und Angelpunkt für die FSMA-Konformität, OSHA-Sicherheit, and customer trust in 2025. This definitive guide fuses the strongest insights from three industry white‑papers and aligns every recommendation with Google’s latest Helpful Content and E‑E‑A‑T guidelines.

Quick‑Glance Wins

-

✅ Cut spoiled frozen shipments ≥ 35% with block‑pellet hybrids

-

❄️ Hold –78 °C for 50 h using VIP + Graphen-Liner

-

📋 Pass audits fast with NFC data + CO₂ ppm logs

Inhaltsverzeichnis

-

Why –78 °C Is the Gold Standard

-

Größe & Packing Formula (1 kg : 3 L Rule)

-

Minute‑by‑Minute Monitoring SOP

-

Technik & Material Upgrades for 2025

-

Regulatory Cheat -Blatt (FSMA, PUNKT, Iata, OSHA)

-

Dry Ice vs. PCM vs. Gel Packs

-

Aktionsplan & KPI Dashboard

-

FAQ

Why –78 °C Is the Gold Standard

-

Pathogen control: Listeria growth is arrested below –18 °C; starting at –78 °C grants a ≥ 60 °C safety buffer.

-

Latent heat advantage: 571 kJ kg⁻¹ absorbed on sublimation—1.7× water ice—means less mass for the same cooling power.

-

Residue‑free logistics: Sublimation produces no meltwater, preserving packaging integrity and unboxing UX.

Schlüsselstatistik: Warming from –78 °C to –70 °C doubles CO₂ off‑gas rate, reaching OSHA’s 5 000 ppm limit ~28 % sooner.

Größe & Packing Formula (1 kg : 3 L Rule)

Formel:

Dry ice mass (kg) = Container volume (L) ÷ 3 × Holding‑hour factor

Holding‑hour factor

| Ambient °C | 24 H | 48 H | 72 H |

|---|---|---|---|

| 15 °C‑25 °C | 1 | 1.7 | 2.4 |

| 25 °C‑35 °C | 1.3 | 2.0 | 2.8 |

Best practice stack

-

Pre‑condition shipper to 4 °C (30 min).

-

Schichtung: Block (unten) → product → pellets (Lücken) → block (Spitze).

-

Entlüftung: two 2 mm ports; never tape lid shut.

-

Lückenfüllung: recycled paper pads to limit convective loops.

Minute‑by‑Minute Monitoring SOP

| Schritt | Werkzeug | Spezifikation | Zweck |

|---|---|---|---|

| Probe install | Type T/K thermocouple | ±0.5 °C, 15 s response | Core pack temp |

| Logger setup | Bluetooth/NFC datalogger | 60‑day battery, –90 °C range | Audit trail & live alerts |

| CO₂-Sicherheit | Dual‑range NDIR sensor | 0‑20 000 ppm, 1 min cadence | OSHA compliance |

| Kalibrierung | Certified –80 °C bath | Wöchentlich | Rückverfolgbarkeit |

Alarm thresholds

-

Temperatur: > –65 °C triggers SMS/email

-

Co₂: > 4 000 ppm triggers vent‑servo open 15 %

Technik & Material Upgrades for 2025

| Innovation | Lift (vs. 2023 Grundlinie) | Wie es funktioniert | ROI |

|---|---|---|---|

| CCR -Dense Pellets (1.8 g cm⁻³) | –12 % sublimation rate | Higher density from carbon‑capture feedstock | 7 months |

| Graphene‑infused liners (R +15 %) | +6 h hold time | Reflective micro‑layers cut radiative gain | 10 months |

| Smart vent caps (IoT) | –23 % CO₂ excursions | Servo throttles based on ppm sensor | 5 months |

| PCM‑Dry Ice Hybrid Pads (–10 ° C) | +46 h buffer above payload | PCM absorbs radiant spikes | 8 months |

Regulatory Cheat -Blatt (Update 08 Aug 2025)

-

FSMA: Log ≤ –18 °C for frozen foods; retain 2 years.

-

DOT 49 CFR §173.217: ≤ 440 lb per vehicle without hazmat CDL; “UN 1845 Dry Ice” diamond + Nettogewicht.

-

Hier ist PI954: ≤ 2.5 kg in passenger baggage; declare net weight on air waybill.

-

OSHA 29 CFR 1910.1000: 5 000 ppm CO₂ TWA; mandate cab venting for loads > 50 lb.

Dry Ice vs. PCM vs. Gel Packs

| Parameter | Dry Ice –78 °C | PCM –26 °C | Gel Pack 0 °C |

|---|---|---|---|

| Starting temp | –78 ° C. | –26 °C | 0 ° C |

| 48 h core temp (R‑6 EPS) | –18 ° C. | –8 ° C | +3 ° C |

| Hazmat label | Ja | NEIN | NEIN |

| Wiederverwendbar | NEIN | 30× | 20× |

| Beste Verwendung | mRNA, Eiscreme | Gebäck, gefrorene Desserts | produzieren, Insulin |

Entscheidungsregel: If product fails above –20 °C, choose dry ice; if freeze‑sensitive, use PCM or gel.

Aktionsplan & KPI Dashboard

| KPI | Ziel | Werkzeug | Review Cadence |

|---|---|---|---|

| % loads ≤ –18 °C on delivery | 99 % | NFC loggers | Wöchentlich |

| Spoilage claims | < 1 % of value | ERP returns module | Monatlich |

| Avg. CO₂ ppm in cab | < 2 000 | NDIR sensor | Trip end |

| Dry Ice cost / shipment | –15 % YoY | TMS analytics | Quarterly |

FAQ

How long will 5 lb of dry ice last in an R‑6 box at 25 °C?

Rund 18–24H. Add ~20 % mass per extra 10 °C ambient rise.

Is –65 °C cold enough for mRNA vaccines?

NEIN. Pfizer/Moderna require ≤ –60 °C only for last‑mile thaw; bulk transport must stay ≤ –70 °C.

Do I need vents in a ground shipment under the DOT exemption?

Ja. Venting is always mandatory to avoid pressure and CO₂ buildup, even below hazmat thresholds.

Can PCM plates replace dry ice entirely by 2025?

For many frozen desserts and pastries—yes. For ultra‑cold biologics—not yet; PCM plates currently bottom at –50 °C.

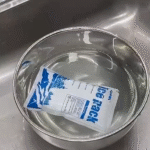

How do I safely dispose of leftover dry ice?

Leave it to sublime in a well‑ventilated area. Never place in a sink or sealed bin.