Transporting gelato requires precision and care to maintain its creamy texture and flavor. Efficient cool chain gelato equipment is essential for preserving its quality during shipping, ensuring the perfect temperature is maintained from production to delivery. In diesem Artikel, we will explore the latest advancements in cool chain technology for gelato, focusing on equipment that optimizes temperature control.

Schlüsselpunkte:

-

Importance of Efficient Equipment for Gelato Shipping: Learn why maintaining the right temperature is crucial for preserving gelato’s texture and flavor.

-

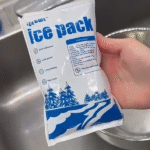

Core Components of Gelato Shipping Equipment: Discover the equipment that keeps your gelato fresh, einschließlich Isolierbehältern, Gelpackungen, and temperature monitoring devices.

-

Nachhaltigkeit und Kosteneffizienz: Understand how modern cool chain technologies contribute to energy savings and environmental sustainability.

Why is Efficient Equipment Essential for Gelato Shipping?

Gelato is a delicate product that must be kept at a stable, low temperature to preserve its creamy texture. Efficient cool chain equipment ensures that the cold chain remains intact, preventing melting, Texturverschlechterung, or contamination during transit. This equipment includes insulated containers, Gelpackungen, and sophisticated temperature monitoring devices.

Core Components of Cool Chain Gelato Equipment

-

Isolierte Behälter: These specially designed boxes maintain the required low temperature during transport.

-

Gelpackungen und Trockeneis: Used to keep gelato frozen during shipment, ensuring it stays at the optimal temperature.

-

Temperaturüberwachungsgeräte: These sensors and real-time tracking systems ensure the gelato is always stored at the correct temperature, providing alerts if conditions change.

How Does Insulation Affect Gelato Quality During Shipping?

Proper insulation is crucial for maintaining gelato’s texture and preventing unwanted temperature fluctuations. High-quality insulation prevents gelato from melting or forming ice crystals, which could ruin its smooth, creamy consistency.

Types of Insulated Packaging for Gelato Shipping

-

VIP (Vakuum -isolierte Panels): Offers superior insulation and long-term temperature stability, ideal for extended transit times.

-

EVP (Erweiterter Polypropylen): Leicht, dauerhaft, and perfect for short-term transport.

-

Polyurethanschaum: A reliable option for standard shipping but bulkier than VIP and EPP solutions.

Beispiel aus der Praxis: A major gelato producer switched to VIP insulation for shipments and experienced a 30% reduction in temperature-related complaints, Kundenzufriedenheit deutlich verbessern.

The Role of Temperature Monitoring Systems in Gelato Shipping

Temperature monitoring systems are vital for ensuring that gelato stays at the correct temperature throughout its journey. These systems allow shippers to track temperature fluctuations in real-time and intervene when necessary, preventing spoilage and ensuring that gelato arrives at its destination in perfect condition.

| Gerät | Funktion | Benutzernutzen |

|---|---|---|

| IoT -Sensoren | Tracks temperature in real-time | Ensures precise temperature control |

| Datenlogger | Records temperature over time | Provides transparency and compliance |

| GPS-Enabled Tracking | Monitors location and conditions | Reduces errors and ensures timely delivery |

How Does Efficient Equipment Contribute to Sustainability?

Many modern cool chain solutions are designed with sustainability in mind. Zum Beispiel, EPP insulated boxes are made from recyclable materials, while energy-efficient temperature control systems minimize the carbon footprint. Investing in eco-friendly equipment reduces waste and supports a sustainable business model.

Practical Tips for Gelato Shipping Efficiency

-

Use multi-use insulation systems: Wiederverwendbare Verpackungen reduzieren Abfall und Kosten.

-

Implement real-time tracking: Stay on top of temperature changes and avoid spoilage.

-

Store gelato at the right temperature before shipping: Ensure your gelato is pre-cooled and ready for transport.

What Are the Latest Innovations in Cool Chain Gelato Equipment?

In 2025, gelato shipping technology continues to evolve with innovations that improve efficiency, Nachhaltigkeit, and product integrity. Zu den wichtigsten Trends gehören::

-

Intelligente Kühlung: Adaptive cooling systems adjust to fluctuations in temperature to maintain optimal conditions.

-

AI-Driven Packaging Solutions: Packaging materials that automatically adjust to external conditions to maintain the ideal internal temperature.

-

Biodegradable Insulation: Materials that naturally break down, Reduzierung der Umweltauswirkungen.

How Does AI Improve Gelato Shipping?

AI is transforming the cold chain industry, and gelato shipping is no exception. AI-driven systems optimize cooling by adjusting temperature settings based on real-time data, improving product quality while reducing energy consumption.

Beispiel: A gelato distributor adopted AI-powered temperature adjustments, which led to improved product quality and reduced energy use.

Häufig gestellte Fragen

What is the ideal temperature for shipping gelato?

The ideal temperature is -20°C (-4° F) or lower to prevent melting and preserve the gelato’s texture.

How long can gelato stay frozen during shipping?

With proper equipment, Gelato kann bis zu gefroren bleiben 72 Std., depending on insulation and cooling methods.

Abschluss

Efficient cool chain gelato equipment is essential for ensuring the highest quality during transport. By using advanced technologies such as insulation, Echtzeit-Temperaturüberwachung, und umweltfreundliche Lösungen, businesses can preserve the quality of gelato while reducing their environmental footprint. Stay ahead of the curve by integrating these technologies into your shipping processes to deliver fresh, high-quality gelato every time.

Umsetzbare Empfehlungen:

-

Invest in smart temperature monitoring systems to ensure proper cooling and avoid temperature fluctuations.

-

Switch to reusable, Umweltfreundliche Verpackung to reduce waste and improve sustainability.

-

Adopt AI-driven cooling systems for dynamic temperature adjustments during shipping.