Pack de glace carbonique 7×13: Comment dimensionner et expédier 2025?

Si vous expédiez des marchandises surgelées, un pack de glace carbonique 7×13 donne un contrôle de congélation pendant 24 à 72 heures lorsqu'il est de bonne taille et ventilé. Vous devez appliquer les marques UN1845, déclarer le poids net de glace carbonique, et suivre 2025 Règles IATA/OSHA pour éviter les retards ou les problèmes de sécurité. Ce guide fusionne les meilleures pratiques, une formule de dimensionnement simple, et des listes de contrôle de conformité que vous pouvez utiliser aujourd'hui.

-

Choisissez quand un pack de glace carbonique 7×13 bat le gel ou le PCM pour expédition congelée.

-

Calculez le nombre de paquets avec une formule rapide et un outil d'une minute.

-

Étiqueter et ventiler correctement sous UN1845, Voici pi 954, et 49 Règles du CFR.

-

Réduisez les risques grâce aux EPI, stockage, et modèles d'emballage spécifiques aux voies.

Qu'est-ce qu'un sac de glace carbonique 7×13, et quand faut-il l'utiliser?

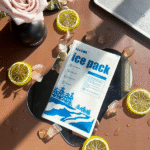

Un sac de glace carbonique 7×13 est une pochette ventilée de 7 × 13 pouces que vous remplissez de granulés de glace carbonique, fournissant un refroidissement de source à −78,5 °C pour les voies gelées. Utilisez-le lorsque votre charge utile doit arriver complètement gelée pendant 24 à 72 heures et vous pouvez suivre les règles de marquage des matières dangereuses et de ventilation.. Il niche dans les coins, réduit les entrefers, et s'adapte efficacement aux petites glacières à colis.

Pourquoi c'est utile pour vous: Le format couvre les petites charges sans suremballage lourd. Il ne produit pas d'eau de fonte, garde les cartons au sec, et simplifie l'acceptation lorsque vous marquez UN1845 et indiquez les kilogrammes nets. Si votre bande cible est comprise entre 2 et 8 °C, envisagez le PCM ou un hybride pour éviter de trop refroidir les produits sensibles.

Règles empiriques de dimensionnement pour le sac de glace carbonique 7×13 charges

Commencer par ~1 à 1,5 lb (0.45–0,7kg) de glace sèche par 24 h pour 6 à 8 L de volume isolé, puis échelle pour la durée et la saison. Arrondissez votre décompte final car la sublimation démarre dès que les pellets sont chargés. Pour les itinéraires chauds, ajouter 25 à 50 % de plus que les références hivernales.

| Impact des composants du packout | Qu'est-ce que c'est | Que vérifier | Ce que cela signifie pour vous |

|---|---|---|---|

| Source de glace carbonique | CO₂ solide à −78,5 °C | Taille, fraîcheur | Performances ultra-froides prévisibles sans résidus liquides. |

| 7×13 sachet | Pochette ventilée sans danger pour le CO₂ | Intégrité des coutures, chemin de ventilation | Fuites de gaz; risque de rupture réduit et acceptation de l’air plus facile. |

| Expéditeur isolé | PSE, PPE, VIP, glacières rigides | Valeur R, pack serré | Sublimation inférieure et temps de maintien plus long pour la même masse. |

Conseils et suggestions pratiques

-

Colis de produits surgelés: Précongeler en dessous de −18 °C; une couverture supérieure pack de glace carbonique 7×13 et placez-en un autre le long du mur chaud.

-

Échantillons de laboratoire: Utiliser le confinement secondaire; positionner les paquets autour des racks, pas directement sur les flacons fragiles.

-

Voies d'été: Augmenter la taille du pack de glace carbonique 7×13 comptez de 25 à 50 % et aérez le chemin du couvercle.

Cas réel: Une marque de desserts en utilisait deux pack de glace carbonique 7×13 unités dans un 10 L expéditeur pour 2 jours aériens pendant 32 ° C ambiant. Les pintes sont arrivées solides comme le roc et les cartons sont restés secs car la neige carbonique se sublime, ne fond pas.

Combien de pack de glace sèche 7×13 unités dont vous avez besoin pour 24 à 72 heures?

Utilisez une calculatrice en trois étapes: estimation 24 h besoin du volume, échelle par heures et facteur de voie, puis convertissez les kilogrammes en paquets. Cela permet de dimensionner de manière transparente et reproductible dans toutes les équipes. Gardez l'emballage aéré; Les règles américaines exigent le rejet de CO₂.

Conseils élargis: Commencez par la référence basée sur le volume, multiplier par le temps et un facteur de voie (1.0 cool, 1.25 moyenne, 1.5 chaud), puis divisez par votre remplissage typique par paquet. Placez-en un pack de glace carbonique 7×13 sur la surface à gain de chaleur la plus élevée (généralement le haut) et un autre près du côté de l'étiquette. Validez sur des voies réelles avec des enregistreurs de données.

Micro-calculatrice: estimateur rapide pour le pack de glace carbonique 7×13

| Exemple de voie | Volume (L) | Heures | Facteur de voie | Résultat | Pour toi |

|---|---|---|---|---|---|

| Vol intérieur 2 jours | 10 | 48 | 1.25 | 2–3 pack de glace carbonique 7×13 | Ajoutez-en un en haut, un mur chaleureux. |

| Colis saison chaude | 14 | 36 | 1.5 | 3–4 paquets | Augmenter la masse; réduire les vides. |

| Du jour au lendemain, Expéditeur VIP | 8 | 24 | 1.0 | 1–2 paquets | Valider; peut réduire la masse. |

Exemple réel: Un expéditeur de diagnostics a réduit les plaintes en passant à deux pack de glace carbonique 7×13 plus un couvercle ventilé; les traces de l'enregistreur ont confirmé la stabilité sur 48 heures.

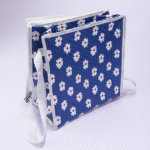

Conformité et sécurité du pack de glace carbonique 7×13 dans 2025?

Faites quatre choses: emballage de ventilation, Appliquer la classe 9 étiquette, marquer « UN1845 » avec les kilogrammes nets de neige carbonique, et suivez IATA PI 954/49 CFR 173.217. Conservez une copie du 2025 liste de contrôle d'acceptation dans vos SOP. Pour la sécurité des travailleurs, utiliser des cryo-gants, protection des yeux, et une bonne aération.

Pourquoi ça compte pour toi: La conception ventilée empêche l'accumulation de pression, la marque UN1845 et le chiffre en kg net vitesse acceptation du transporteur aérien, et un étiquetage cohérent évite les retours. La limite de CO₂ de 8 heures de l'OSHA est 5,000 ppm; Le NIOSH répertorie l'IDLH à 40,000 ppm : la formation et les moniteurs réduisent les risques dans les zones de rassemblement.

Liste de contrôle d’étiquetage et de documentation

-

Vocation: L'emballage doit permettre le dégagement de CO₂; ne jamais sceller complètement les refroidisseurs.

-

Marquer: Imprimer UN1845 et poids net de glace carbonique (kg) sur la boîte extérieure.

-

Étiqueter: Appliquer la classe 9 étiquette de danger; endroit où visible après manipulation.

-

Documentez-le: Indiquez UN1845 et les kg nets sur la lettre de transport aérien, le cas échéant..

| Élément d'étiquetage | Exigence | Glissement commun | Ce que cela signifie pour vous |

|---|---|---|---|

| Texte UN1845 | Sur emballage extérieur | kg net manquant | Retards ou refus d’acceptation. |

| Classe 9 étiquette | Par IATA/Transporteur | Mauvais emplacement | Retravail et remontée manquée. |

| Chemin de ventilation | « Doit autoriser la libération » | Couvercle à fermeture scotchée | Risque de rupture; non conforme. |

Pack de glace carbonique 7×13 vs gel et PCM : ce qui convient à votre voie?

Choisissez un sac de glace carbonique 7×13 pour les envois qui doivent arriver congelés; choisissez le gel/PCM lorsque vous avez besoin de 2 à 8 °C. La glace carbonique est ultra froide et sans résidus, mais nécessite des marques de matières dangereuses; Le PCM cible des points de consigne étroits et facilite l'acceptation de l'air. Les hybrides gagnent souvent pour les charges mixtes.

En pratique: Une couverture supérieure pack de glace carbonique 7×13 pour protéger les SKU gelés, puis placez +5 Panneaux PCM °C plus proches des éléments sensibles. Cela limite le risque de gel, simplifie la conformité, et peut réduire la masse totale de neige carbonique sur les voies d'été. Valider les profils hiver et été.

Guide de décision: choisir le bon réfrigérant

-

Charges utiles gelées uniquement: Service pack de glace carbonique 7×13 seulement; maximiser l'isolation avant d'ajouter de la masse.

-

Couloirs stricts de 2 à 8 °C: Préférez d’abord le PCM; ajoutez un minimum de tampon de glace carbonique si nécessaire.

-

Télédiques mixtes: Utilisez un diviseur; combiner PCM et pack de glace carbonique 7×13 avec un chemin de ventilation dégagé.

2025 tendances qui façonnent la banquise 7×13 usage

Trois équipes à prévoir 2025: une discipline plus stricte en matière d'acceptation de l'air autour des marques de kg net UN1845; adoption plus large des enregistreurs de données cellulaires/BLE; et la pression de la durabilité qui pousse les PCM hybrides et les expéditeurs à R plus élevé à réduire la masse de glace carbonique. Le résultat est une meilleure surveillance, moins d'erreurs d'acceptation, et un coût par voie inférieur.

Dernier progrès en un coup d'œil

-

Casquettes d'opérateur: Certaines compagnies aériennes exigent de déclarer la masse nette de glace carbonique lors de la réservation pour respecter les limites au niveau de l'avion..

-

Packs connectés: Les enregistreurs disponibles dans le commerce simplifient la surveillance continue et les pistes d'audit.

-

Emballage à R supérieur: VIP et EPP moulé réduisent la sublimation pour le même pack de glace carbonique 7×13 compter.

Perspicacité du marché: La demande pour la chaîne du froid continue d'augmenter avec les produits biologiques et l'épicerie électronique. Attendez-vous à plus de demandes de validation, plus de données de capteurs dans QMS, et davantage d'accent sur la taille correcte pack de glace carbonique 7×13 masse par itinéraire et par saison.

Questions fréquemment posées

Combien de temps durera un sac de glace carbonique 7×13 dernier?

Prévoir 24 à 72 heures selon l'isolation, chaleur ambiante, et remplir la masse. Commencez avec 1 à 1,5 lb par 24 h par 6 à 8 L et arrondir pour les voies chaudes.

Quelles étiquettes sont requises lorsque j'utilise un sac de glace carbonique 7×13?

Appliquer la classe 9 étiqueter et marquer UN1845 avec les kilogrammes nets de glace carbonique sur la boîte; inclure UN1845 et le kg net sur la lettre de transport aérien, le cas échéant.

Est-ce un sac de glace carbonique 7×13 sûr à manipuler?

Oui : utilisez des cryo-gants et une protection oculaire, travailler dans des zones ventilées, et ne jamais sceller le CO₂ dans un récipient hermétique.

Puis-je mélanger un sac de glace carbonique 7×13 avec panneaux PCM?

Oui. Compartiments séparés, garder un chemin de ventilation dégagé, et valider pour protéger les articles à 2-8 °C du gel.

Résumé et recommandations

Points clés: UN pack de glace carbonique 7×13 délivre du froid ultra-froid, performances sans résidus pour les voies gelées. Secouer, marque UN1845 avec kg net, et suivez PI 954/49 Règles du CFR. Redimensionner avec le calculateur en trois étapes, puis validez sur vos voies avec des data loggers. Envisagez des hybrides pour des charges utiles mixtes.

Étapes suivantes: Cartographier les voies par saison et temps d'attente. Pilotez deux packouts avec des pack de glace carbonique 7×13 compte. Mettre à jour les sops avec 2025 étiqueter/marquer les étapes et ajouter la liste de contrôle d'acceptation. Intégrez le calculateur sur votre site. CTA: Demandez un emballage et un kit de documentation validés à Tempk.

À propos du tempk

Nous sommes une équipe d'emballage et de conformité de la chaîne du froid axée sur les aspects pratiques, packouts validés. Nous construisons des calculatrices, Sops, et des kits spécifiques à la voie, y compris pack de glace carbonique 7×13 configurations – pour réduire les délais d'expédition. Nos points forts résident dans la clarté de la réglementation et dans les processus de validation basés sur des données afin que vous puissiez évoluer en toute confiance..