Pack de congélation en gel Fabricant américain: Comment choisissez-vous?

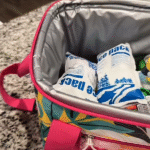

Si vous choisissez un pack de gel congélateur fabricant américain, you are really choosing predictable temperature control. Your box may travel 24–72 hours through hot trucks, retards sur le porche, et une manipulation brutale. Dans de nombreuses voies, gel packs hold cold far longer than loose ice while keeping packaging clean and dry. Votre objectif est simple: fewer warm arrivals, moins de fuites, et moins de réclamations clients.

Cet article vous aidera à répondre:

How to qualify a gel freezer pack USA manufacturer using cooling-curve proof and traceability

What to request for food grade gel freezer packs documentation and safety control

How a gel freezer pack USA manufacturer matches packs to your 24/48/72-hour lane

How to run cold chain packout validation without a lab

How to compare total cost per successful delivery, not just pack price

What should a gel freezer pack USA manufacturer prove first?

A reliable gel freezer pack USA manufacturer should prove three things: cooling performance, package integrity, and repeatability. “Cold enough” is not a spec, because the risk happens at the end of the route. You want evidence that the same packout performs across batches and seasons. When a manufacturer can show proof quickly, your sourcing process becomes safer and faster.

A strong gel freezer pack USA manufacturer should also speak in outcomes you care about. That means time-in-range, taux de fuite, and clear lot coding. If you only get photos and unit pricing, you are buying blind. Proof beats promises every time.

A simple proof checklist for buyers

| Zone d'épreuve | Ce que tu demandes | Ce que vous devriez recevoir | Ce que cela signifie pour vous |

|---|---|---|---|

| Cooling performance | Cooling curve evidence | Résumé + plot from lane test | Fewer warm arrivals |

| Prévention des fuites | Joint + film controls | QC method + acceptance limits | Fewer leaks and wet boxes |

| Répétabilité | Lot traceability | Codes de lot + enregistrements de lots | Faster root-cause fixes |

Conseils pratiques que vous pouvez utiliser aujourd'hui

Use one “worst lane” d'abord: qualify the gel freezer pack USA manufacturer on your most failure-prone route.

Demand batch consistency: ask for fill-weight tolerance (exemple: ±2–3%) and how it’s checked.

Ask for failure stories: a trustworthy gel freezer pack USA manufacturer will explain what fails and how they prevent it.

Exemple pratique: One subscription shipper reduced complaints after switching to a gel freezer pack USA manufacturer that tightened fill control and upgraded seal width.

Résumé et recommandations

A dependable gel freezer pack USA manufacturer should prove performance, document safety, and produce consistently at scale. Start by defining your lane, then run a simple 3-run validation. Prioritize seal integrity, traçabilité, and change control. These levers reduce warm arrivals, fuites, and refunds while lowering total cost per successful delivery.

À propos du tempk

We design and manufacture cold-chain temperature control packaging, including gel freezer packs for food, médical, and pharmaceutical shipping. We focus on consistent fill control, robust sealing, and traceable production so your packouts perform in real routes. We also help you validate layouts and reduce pack count without risking temperature stability.

Prêt à améliorer votre chaîne du froid? Talk with our team to plan a lane test and choose the right gel freezer pack configuration for your shipments.