Introduction:

Garder la viande sûre et rentable 2025 signifie équilibrer un contrôle strict de la température, consommation d’énergie et évolution des attentes des consommateurs. Solutions pour la viande sous chaîne du froid se concentrer sur la conservation de la viande réfrigérée entre 0 et 4 °C et de la viande congelée à −18 °C ou moins. L’industrie s’attaque à une forte consommation d’énergie : les entrepôts réfrigérés brûlent 40–60 kWh par pied carré chaque année avec des équipements de réfrigération consommant >70 % de l’électricité, tout en luttant pour la durabilité et la transparence. Ce guide (mis à jour en décembre 2025) montre comment optimiser la gestion de la température, adopter des emballages écologiques, réduire les coûts énergétiques et se préparer aux dernières réglementations.

Contrôle de la température et sécurité: Comprendre pourquoi la viande doit rester dans des bandes précises et ce qui se passe lorsque la chaîne se brise.

Emballage durable & technologie intelligente: Découvrez les plateaux recyclables, des emballages actifs et des jumeaux numériques qui prolongent la durée de conservation et renforcent la confiance.

Efficacité énergétique & réduction des coûts: Découvrez comment augmenter le point de consigne de gel à -15 °C peut réduire la consommation d'énergie de 5 à 7 %, économiser des millions de tonnes de CO₂.

IoT, IA & blockchain: Découvrez comment les capteurs, La planification d'itinéraires par l'IA et la blockchain améliorent la traçabilité et l'efficacité.

Tendances du marché & conformité: Préparez-vous aux défis du travail, FSMA 204 traçabilité et nouvelles normes de durabilité.

Pourquoi un contrôle précis de la température est-il au cœur des chaînes du froid de la viande?

Répondre: La sécurité sanitaire de la viande dépend du maintien de la viande réfrigérée entre 0 et 4 °C et de la viande congelée à ≤ −18 °C.. Les écarts permettent aux bactéries de se multiplier et provoquent des pertes au goutte-à-goutte ou des rappels. Les principales entreprises de viande de la chaîne du froid utilisent la surveillance en temps réel, flottes reefer dédiées et emballages isothermes pour maintenir ces gammes.

Comprendre les bandes de stockage frigorifique

La qualité de la viande fraîche se détériore rapidement en dehors de sa fenêtre de température. Produits réfrigérés conservés au-dessus 4 °C peut abriter des agents pathogènes dangereux; geler en dessous 0 °C endommage les fibres musculaires et libère des jus. Les charges congelées doivent rester à -18 °C ou moins pour arrêter la croissance microbienne. La viande rouge de grande valeur est parfois stockée dans un bande de « super refroidissement » proche du point de congélation de –1 à +1 °C pour prolonger la durée de conservation sans former de gros cristaux de glace. Cadres réglementaires tels que la loi sur la modernisation de la sécurité alimentaire de la FDA (FSMA) et les mandats de l'USDA traitent toute excursion de température au-delà de ces bandes comme un risque de contamination.

Catégories réfrigérées et surgelées: ce qu'ils signifient pour toi

| Catégorie de stockage | Point de consigne & contrôle aérien | Limite de produit | Ce que cela signifie pour vous |

| Cool | 8–15 °C ±1–2 °C | ≤15 °C | Utilisé pour les zones de rassemblement; pas assez froid pour la viande. |

| Glacé (aliments généraux) | 0–5 °C ±1 °C | ≤5 °C | Réfrigération standard pour les produits laitiers et les aliments prêts à consommer. |

| Viande fraîche & volaille | 0–2 °C ±0,5 °C | ≤2 °C | Minimise les pertes par égouttement et la croissance microbienne, au cœur de la chaîne du froid de la viande. |

| Près du point de congélation / super froid | –1 à +1 °C ±0,5 °C | ≤2 °C | Prolonge la durée de conservation de la viande rouge de première qualité. |

| Aliments surgelés | ≤−18 °C | n / A | Nécessaire pour le stockage à long terme; ralentit la perte de qualité. |

| Surgelé / congélation rapide | –30 °C à –45 °C | ≤−18 °C | Utilisé pour la congélation rapide des noyaux et les coupes spéciales comme le sashimi. |

Conseils pratiques pour maintenir la température

Utiliser la surveillance en temps réel: Installez des capteurs IoT et des enregistreurs de données compatibles GPS pour détecter instantanément les écarts. Les alertes permettent aux chauffeurs ou au personnel de l'entrepôt d'agir avant que la détérioration ne se produise.

Optimiser la préparation et le chargement: Pré-refroidir les zones de préparation et former le personnel pour minimiser le temps d'ouverture des portes pendant la palettisation, chargement et déchargement.

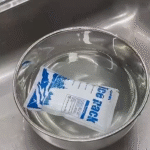

Choisissez un emballage approprié: Conteneurs isolés, packs de gel et matériaux à changement de phase (PCMS) aider à maintenir la température interne, surtout sur le dernier kilomètre.

Documentation et audit: Les régulateurs et les clients exigent la preuve que les limites de température ont été respectées. Tenir des journaux électroniques, certificats d'étalonnage et rapports d'actions correctives.

Étude de cas: Un distributeur de viande de taille moyenne au Texas a installé des capteurs de température en temps réel dans ses camions frigorifiques. Alertes déclenchées lorsque le reefer atteint 3.5 °C, incitant les conducteurs à régler la réfrigération. Les taux de rejet ont diminué 40 % et deux rappels potentiels ont été évités.

Comment la rupture des chaînes du froid affecte la qualité

Même des pointes courtes peuvent raccourcir la durée de conservation ou déclencher des rappels. Un réchauffement de la viande congelée au-dessus de −18 °C peut en souffrir recristallisation, texture dégradante et permettant aux microbes de réapparaître, tout en congelant la viande fraîche ci-dessous 0 °C peut provoquer perte au goutte-à-goutte en raison de la rupture des fibres musculaires par des cristaux de glace. La teneur élevée en humidité et en protéines rend la viande idéale pour les bactéries; par conséquent, une réfrigération continue depuis le traitement jusqu'à la distribution est obligatoire.

Quelles avancées en matière d'emballage gardent la viande fraîche et respectueuse de l'environnement?

Répondre: Les emballages durables et les technologies intelligentes prolongent la durée de conservation tout en réduisant les déchets et l'empreinte carbone. PET recyclable, Les barquettes en rPET et en papier dominent le secteur de la viande en 2025. Les films compostables comme le PLA et la cellulose gagnent du terrain. L'emballage actif utilise des agents antimicrobiens et des capteurs d'oxygène, tandis que l'emballage intelligent intègre des indicateurs de température et de temps, Codes QR et capteurs numériques. Emballage sous atmosphère modifiée (CARTE) remplace l'oxygène par du CO₂ et du N₂ pour ralentir la détérioration.

Durable & emballage intelligent expliqué

La durabilité n’est plus une option. Les barquettes mono-matériau en PET ou polypropylène recyclable réduisent le plastique vierge et s'alignent sur les objectifs d'économie circulaire. PET recyclé (rPET) offre d'excellentes propriétés d'étanchéité et de barrière; les films à base de papier offrent une alternative compostable tout en permettant la visibilité du produit. Matériaux compostables, y compris le PLA, films de cellulose et revêtements biodégradables : attrait pour les marques biologiques mais nécessitent un équilibre minutieux entre performance barrière et usinabilité.

L'emballage actif prolonge la durée de conservation en intégrant des agents antimicrobiens, des désoxygénants ou des absorbeurs d'humidité dans l'emballage. Cela ralentit la croissance microbienne sans produits chimiques supplémentaires. L'emballage intelligent va plus loin en intégrant des indicateurs de temps et de température, Codes QR et capteurs IoT; ils enregistrent l'historique des températures et peuvent déclencher des alertes en cas de rupture de la chaîne. Les consommateurs scannent les codes QR pour accéder à la provenance, informations sur la fraîcheur et la conformité.

Emballage sous atmosphère modifiée (CARTE) reste un incontournable de la technologie. Par remplacer l'oxygène par du CO₂ et du N₂, MAP ralentit l’oxydation et la croissance bactérienne, ce qui entraîne une durée de conservation plus longue, couleur constante et réduction des déchets. De nombreux détaillants spécifient désormais MAP pour les steaks et les hamburgers en raison de ses avantages prouvés.

Tableau: Options d'emballage pour les chaînes du froid de la viande

| Type d'emballage | Matériaux clés & caractéristiques | Impact sur la fraîcheur & durabilité | Avantage pratique |

| Barquettes recyclables | ANIMAL DE COMPAGNIE, rPET, polypropylène; matériaux mono | Réduisez le plastique vierge et alignez-vous sur les mandats circulaires | Convient aux lignes à grande vitesse; flux de recyclage simples |

| Films compostables | PLA, cellulose, revêtements biodégradables | Impact environnemental moindre mais peut nécessiter des barrières plus épaisses | Idéal pour les produits écolabellisés et les marques bio |

| Emballage actif | Antimicrobiens ou piégeurs d'oxygène intégrés | Retarde la détérioration et prolonge la durée de conservation | Utile pour les itinéraires de distribution ou d'exportation plus longs |

| Emballage intelligent | Indicateurs de température et de temps, Codes QR, Capteurs IoT | Fournit une traçabilité en temps réel et renforce la confiance des consommateurs | Permet la gestion des rappels et le marketing interactif |

| Plateaux MAP | Remplacer O₂ par CO₂ et N₂ | Ralentit l'oxydation et préserve la couleur | Prolonge la durée de conservation, réduire les déchets du commerce de détail |

Conseils pour choisir un emballage en fonction de votre scénario

Exportations longue distance: Utilisez MAP combiné à un emballage actif pour maintenir la fraîcheur lors des expéditions sur plusieurs semaines.

Commerce électronique & livraison du dernier kilomètre: Choisissez des conteneurs isolés légers avec des packs de gel; intégrer un code QR pour un suivi en temps réel et l'engagement des consommateurs.

Marques biologiques ou spécialisées: Optez pour des films compostables ou des barquettes à base de papier pour signaler la durabilité et exploiter des marchés soucieux de l'environnement..

Exemple: Un exportateur de produits de la mer a opté pour des conteneurs isothermes intelligents équipés de capteurs de température et GPS. Des alertes en temps réel ont permis des actions correctives immédiates, réduire les réclamations pour détérioration en 15 % et améliorer la confiance des clients.

Comment les solutions pour la chaîne du froid de la viande peuvent-elles améliorer l'efficacité énergétique et la durabilité?

Répondre: Réduire la consommation d’énergie dans les entrepôts frigorifiques est essentiel pour la rentabilité et les objectifs climatiques. Les entrepôts frigorifiques consomment 40–60 kWh par pied carré par an, avec comptabilité de réfrigération pour >70 % de l'électricité. Modification du point de consigne de stockage congelé de –18 °C à –15 °C peut réduire la consommation d'énergie en 5–7 % (jusqu'à 10-12 % à certaines étapes) et réduire les émissions mondiales de carbone en 17.7 millions de tonnes par an. Chaque degré en dessous de la température minimale requise utilise 2–3 % plus d'énergie, tandis que les pertes de nourriture dues à un contrôle inadéquat de la température atteignent 12 % à l'échelle mondiale.

Coûts cachés et arguments en faveur d’une augmentation du point de consigne

Maintenir des températures inférieures à zéro consomme beaucoup d’énergie. Un entrepôt réfrigéré typique utilise environ 24.9 kWh par pied carré chaque année, alors qu'un entrepôt sec utilise uniquement 6.1 kWh. Les installations plus anciennes peuvent consommer 40–60 kWh/pi², avec des systèmes de réfrigération utilisant 70 % de l'électricité. L’énergie est souvent le deuxième coût d’exploitation après la main-d’œuvre.

Le Passer à −15 °C la campagne démontre que l'augmentation du point de consigne réduit la consommation d'énergie tout en préservant la sécurité alimentaire. La modélisation scientifique suggère un 5–7 % réduction d’énergie tout au long de la chaîne du froid, équivalente à 25 TWh par an— et des économies de carbone équivalentes au retrait de quatre millions de voitures de la route. Des essais montrent que la plupart des aliments surgelés restent sans danger à −15 °C, permettre aux entreprises de réinvestir leurs économies dans l'automatisation et la technologie.

Optimisation des systèmes de réfrigération

La mise à niveau des équipements de réfrigération permet des économies significatives:

Compresseurs et entraînements à vitesse variable: Ceux-ci ajustent la vitesse du moteur en fonction de la demande de refroidissement. UN 2023 étude de cas sur une vitrine de glaces avec un compresseur R290 à vitesse variable réalisée 20 % économies d'énergie par rapport aux unités à vitesse fixe. Un essai à grande échelle réalisé par Cold Summit Development a montré un 62 % réduction dans la consommation d'électricité par rapport aux systèmes au fréon existants et un 30 % amélioration par rapport aux systèmes modernes à ammoniac.

Tête flottante et commandes d'aspiration: La modernisation des condenseurs avec des commandes de pression à tête flottante et des détendeurs électroniques peut réduire la charge du compresseur de 15–45 %.

Entretien & fruit à portée de main: Serpentins de nettoyage, la lubrification des pièces et la vérification de la charge de réfrigérant améliorent les performances; l'installation de variateurs de fréquence sur les ventilateurs et les pompes peut réduire les coûts d'électricité en 30–50 %. Le passage à l'éclairage LED réduit la charge thermique et permet d'économiser 68–85 % énergie.

| Mesure d'optimisation énergétique | Économies typiques | Signification pratique |

| Augmenter le point de consigne gelé à –15 °C | 5–7 % réduction d'énergie à l'échelle de la chaîne | Un changement à faible coût qui réduit à la fois les coûts et les émissions de CO₂ |

| Compresseurs à vitesse variable & VSD | 20–62 % réduction d'énergie | Correspond à la demande de refroidissement, améliore la stabilité de la température |

| Pression de tête flottante & EEV | 15–45 % réduction de la charge du compresseur | Réduit la pression de fonctionnement et l’usure |

| Moteurs EC & VFD sur ventilateurs/pompes | 30–50 % économies d'électricité | Réduit le bruit et prolonge la durée de vie de l'équipement |

| Rénovations d'éclairage LED | 68–85 % économies d'énergie | Moins de charge thermique et une durée de vie plus longue |

Enveloppe du bâtiment & énergie renouvelable

Isolation et étanchéité à l'air: Panneaux métalliques isolés (IMP) fournir un air tout en un, barrière à l'eau et thermique avec des valeurs R jusqu'à 72. L'amélioration de l'isolation et de l'étanchéité des portes réduit la charge de réfrigération; la rénovation des vitrines ouvertes avec des portes ou des couvertures de nuit peut réduire les pertes d'énergie en 20–75 %.

Contrôle des infiltrations d'air: Clôture des quais de chargement, l'ajout de rideaux d'air et la formation du personnel pour garder les portes fermées minimisent l'infiltration d'air chaud.

Énergie renouvelable: Les panneaux solaires sur le toit associés à un stockage sur batterie fournissent une énergie propre et protègent contre la hausse des coûts de l'électricité.. Une coopérative laitière a installé un 1 MW panneau solaire avec 1.5 MWh stockage; solaire fourni 40 % de son électricité annuelle et économisé 210 000 $ US par année.

Pourquoi la durabilité est importante

L’industrie alimentaire est responsable d’environ un tiers des émissions mondiales. En réduisant la consommation d’énergie, relever les points de consigne et adopter les énergies renouvelables, les entreprises de viande peuvent réduire leur empreinte carbone et atteindre leurs objectifs ESG. L'emballage joue également un rôle: le passage à des matériaux recyclables et compostables et la réduction des déchets plastiques correspondent aux attentes des consommateurs et aux exigences réglementaires.

Quel rôle joue l'IoT, La blockchain et l'IA jouent dans les chaînes du froid de la viande?

Répondre: Les technologies numériques fournissent des données en temps réel, informations prédictives et traçabilité, rendre les chaînes du froid plus résilientes. Les capteurs IoT surveillent la température, humidité et emplacement; la blockchain garantit un enregistrement immuable de chaque transfert; et l'IA optimise les itinéraires et prédit les besoins de maintenance. Ces outils réduisent la détérioration, rationaliser la logistique et améliorer la transparence.

Surveillance intelligente & optimisation d'itinéraire

Les appareils IoT suivent en permanence l'état des produits et envoient des alertes si les températures s'écartent. L'intégration de capteurs avec des plates-formes de contrôle à distance permet aux gestionnaires d'ajuster les paramètres de réfrigération à distance pour s'aligner sur les tarifs d'électricité hors pointe.. Le suivi en temps réel protège non seulement les produits, mais fournit également des données pour les audits et la conformité..

L'optimisation des itinéraires basée sur l'IA analyse le trafic, conditions météorologiques et fenêtres de livraison pour planifier des trajets efficaces, réduisant la consommation de carburant et le temps de transport. Pendant la pandémie, de nombreux distributeurs alimentaires se sont tournés vers des modèles de vente directe aux consommateurs; L’IA garantit une livraison à temps et réduit l’exposition à la chaîne du froid.

La blockchain enregistre chaque étape du parcours d'un produit. Lorsqu'il est combiné avec des capteurs IoT, il permet aux parties prenantes de vérifier que la viande est restée dans les plages de température prescrites et n'a pas été altérée. Cette transparence est de plus en plus exigée par les régulateurs et les consommateurs qui veulent savoir d’où viennent leurs aliments et s’ils sont sûrs..

Jumeaux numériques et ERP cloud

Les jumeaux numériques, répliques virtuelles des installations et des processus, permettent aux opérateurs de simuler les changements avant de les mettre en œuvre.. Les entreprises de viande utilisent des jumeaux numériques pour modéliser les ajustements des lignes de conditionnement ou tester de nouveaux itinéraires logistiques, réduisant les temps d'arrêt et les risques. Les systèmes ERP basés sur le cloud intègrent les achats, gestion des stocks et de la qualité, offrant une visibilité en temps réel et une conformité automatique aux exigences FSMA et HACCP. Pour les petits opérateurs, La robotique en tant que service (RaaS) offre une automatisation flexible sans dépenses d'investissement importantes.

Choisir le bon partenaire technologique

Lors de la sélection d'un partenaire de la chaîne du froid, examiner leur pile technologique et leur couverture réseau. Les entreprises leaders se différencient grâce à un contrôle de bout en bout, outils de visibilité et packaging spécialisés. Par exemple:

Maersk exploite ses propres actifs de réfrigération sur tout le territoire, mer et air, offrant un suivi des conteneurs en temps réel via le Capitaine Pierre plate-forme.

UPS Santé utilise des emballages isothermes avec réapprovisionnement en glace carbonique et un centre de commande pour un suivi en temps réel, garantir que les cartons arrivent à –80 °C – une capacité adaptable aux expéditions de viande congelée.

Logistique de la lignée intègre l'apprentissage automatique et l'analyse de données pour optimiser les opérations d'entrepôt et réduire le gaspillage alimentaire.

Amérique maintient un réseau national d'entrepôts à température contrôlée et utilise des systèmes de surveillance avancés pour livrer à 99 % des États-Unis. dans les deux jours.

Ces exemples mettent en évidence la valeur du partenariat avec des prestataires logistiques qui investissent dans une technologie moderne et une infrastructure robuste..

Quelles tendances et réglementations du marché façonnent les solutions pour la chaîne du froid de la viande 2025?

Répondre: La chaîne du froid de la viande est influencée par la croissance rapide du marché, évolution des habitudes de consommation et évolution des réglementations. Le marché mondial de la logistique de la chaîne du froid alimentaire devrait passer de USD 393.2 milliards en 2025 à USD 798.5 milliards 2030 et USD 1.63 mille milliards par 2035—un taux de croissance annuel composé de 15.3 %. Les facteurs déterminants incluent la demande croissante d’aliments frais et biologiques, expansion du commerce électronique et exigences plus strictes en matière de chaîne du froid pharmaceutique.

Principaux moteurs du marché

Croissance de produits sensibles à la température: Médicaments, les produits biologiques et les aliments périssables alimentent la demande de chaînes du froid précises.

Expansion directe vers le consommateur: De nombreux distributeurs B2B sont entrés dans l'espace D2C, proposer des kits de repas et des services de livraison à domicile qui nécessitent une logistique fiable de la chaîne du froid.

Commerce électronique et commodité: Les consommateurs attendent une livraison rapide de produits frais. Les emballages s'adaptent aux plus petits, emballages refermables et formats à portions contrôlées.

Mandats de durabilité: Les entreprises adoptent des emballages écologiques, technologies économes en énergie et énergies renouvelables pour atteindre les objectifs ESG.

Paysage réglementaire et défis

La FSMA 204 la règle exige une traçabilité détaillée pour les aliments à haut risque, prolonger le délai de mise en conformité à 2028. Les entreprises de viande doivent documenter les événements de suivi critiques et conserver des enregistrements électroniques. Les normes de certification évoluent: les détaillants exigent de plus en plus la certification BRC ou SQF, qui met l'accent sur le contrôle avancé de la température et les systèmes de suivi automatisés. La conformité ajoute une pression pour investir dans la surveillance, documentation et formation.

Les transformateurs sont également confrontés à des pénuries de main-d'œuvre, inspections plus strictes de l’USDA et risque d’épidémies (Par exemple, grippe aviaire, Peste porcine africaine). La surveillance environnementale se renforce; les organisations sont censées déclarer leurs émissions, consommation d'eau et gaspillage, et démontrer des réductions.

Tendances technologiques et packaging

Emballage durable – Barquettes recyclables, les matériaux compostables et les films à base de plantes réduisent l'impact environnemental.

Emballage intelligent – Codes QR, les indicateurs de température et de temps et la traçabilité basée sur la blockchain transforment les colis en centres d'information.

Automation & robotique – La pénurie de main d’œuvre accélère l’adoption des bras robotisés pour le pesage, emballage et scellage.

Plus petit, packs en déplacement – Les formats en portion individuelle et refermables s'adressent aux petits ménages et aux consommateurs en déplacement.

Jumeaux numériques & ERP cloud – Les modèles virtuels et les plateformes cloud améliorent la planification et la conformité.

La robotique en tant que service & éco-innovation – La location d’équipements d’automatisation abaisse les barrières, tandis que les films biodégradables et les revêtements comestibles réduisent les déchets.

2025 Tendances: Développements à surveiller

Dynamique du marché et innovation technologique

L'industrie de la chaîne du froid se développe rapidement. Fact.MR prévoit que le marché de la logistique de la chaîne du froid alimentaire passera de USD 393.2 milliards en 2025 à USD 1.632 mille milliards par 2035. Les principales innovations incluent les unités de réfrigération à énergie solaire, conteneurs intelligents légers avec capteurs IoT, Optimisation des itinéraires basée sur l'IA et traçabilité de la blockchain. Des entreprises comme Eja Ice au Nigeria déploient des chambres froides alimentées à l’énergie solaire pour réduire le gaspillage alimentaire. Des véhicules frigorifiques électriques font leur apparition pour les livraisons du dernier kilomètre, offrant des coûts d’exploitation inférieurs et des émissions de carbone réduites.

Passage à −15 °C et durabilité

L’élan se développe pour faire passer le stockage congelé de −18 °C à −15 °C. Les technologies modernes permettent un stockage sûr à des températures plus élevées tout en économisant de l'énergie et en réduisant les émissions.. Les initiatives de développement durable incluent également des emballages respectueux de l'environnement, programmes d’énergie renouvelable et de compensation carbone. Les entreprises doivent équilibrer ces initiatives avec la conformité réglementaire, assurer la certification BRC ou SQF et FSMA 204 préparation.

Insistance au marché

L'Amérique du Nord reste le plus grand marché d'emballage de viande et devrait connaître une croissance de ~4.3 % TCAC. Inflation, les tarifs douaniers et les tensions géopolitiques créent une volatilité dans la chaîne d'approvisionnement; les transformateurs doivent diversifier leurs sources d’approvisionnement et investir dans l’analyse prédictive. La préférence des consommateurs pour une viande durable et traçable conduit à l’adoption d’emballages intelligents et de la blockchain. Les pénuries de main-d'œuvre encouragent l'automatisation et les solutions RaaS.

Questions fréquemment posées

Q1: À quelle température la viande crue doit-elle être conservée pendant le transport?

La viande crue doit être conservée entre 0 et 4 °C pendant le transport pour éviter la croissance bactérienne et la détérioration. Pour les produits surgelés, maintenir à ou en dessous −18 °C.

Q2: Comment l’emballage sous atmosphère modifiée prolonge-t-il la durée de conservation de la viande?

MAP remplace l'oxygène dans l'emballage par un mélange de CO₂ et N₂, ralentir l'oxydation et la croissance bactérienne et préserver la couleur et la texture.

Q3: Pourquoi les entreprises augmentent-elles les températures de stockage congelé de −18 °C à −15 °C?

Augmenter le point de consigne à −15 °C peut réduire la consommation d'énergie en 5–7 % (jusqu'à 10-12 % à certaines étapes) et réduire les émissions mondiales de carbone en 17.7 millions de tonnes par an tout en conservant la qualité du produit.

Q4: Quelles nouvelles technologies d’emballage les transformateurs de viande devraient-ils envisager 2025?

Barquettes recyclables et compostables, emballage actif avec des antimicrobiens, emballage intelligent avec codes QR et capteurs IoT, et MAP sont des technologies clés.

Q5: Comment l'IoT et la blockchain améliorent-ils la transparence de la chaîne du froid?

Les capteurs IoT surveillent la température et l’emplacement en temps réel, tandis que la blockchain fournit un enregistrement immuable de chaque transfert, garantir la conformité et la confiance des consommateurs.

Résumé & Recommandations

Points clés: Le maintien de la sécurité de la viande nécessite un contrôle strict de la température: conserver la viande réfrigérée à 0–4 °C et de la viande congelée à ≤−18 °C. Emballage durable : barquettes recyclables, films compostables, emballage actif et capteurs intelligents : réduit les déchets et prolonge la durée de conservation. L’énergie représente une part importante des coûts de la chaîne du froid; augmenter le point de consigne gelé à −15 °C enregistre 5–7 % énergie et réduit les émissions de carbone. Compresseurs à vitesse variable, isolation améliorée, les énergies renouvelables et les technologies numériques réduisent encore la consommation d’énergie et améliorent l’efficacité. Des outils numériques comme les capteurs IoT, blockchain, L’optimisation des itinéraires par l’IA et les jumeaux numériques garantissent la traçabilité et contribuent à répondre aux exigences réglementaires. Le marché connaît une croissance rapide, porté par le commerce électronique, Modèles D2C et demande de traçabilité, viande durable.

Plan d'action:

Auditer et optimiser les températures: Effectuer un audit de température pour garantir que la viande réfrigérée et congelée reste entre 0 et 4 °C et ≤−18 °C.; envisager d'augmenter les points de consigne de congélation à −15 °C si les produits le permettent.

Investissez dans une surveillance intelligente: Déployer des capteurs IoT, enregistreurs de données et tableaux de bord cloud pour des alertes en temps réel et des rapports de conformité.

Moderniser les équipements de réfrigération: Installer des compresseurs à vitesse variable, commandes à tête flottante et moteurs EC; planifier un entretien régulier et passer à l’éclairage LED.

Améliorer l’enveloppe du bâtiment: Améliorer l'isolation, sceller les portes et moderniser les vitrines; envisager des installations d’énergies renouvelables pour compenser les coûts de l’électricité.

Adopter des emballages durables: Transition vers des barquettes recyclables ou compostables; intégrer des packagings actifs et intelligents; adopter MAP pour les produits nécessitant une durée de conservation plus longue.

Adoptez les technologies numériques: Mettre en œuvre une traçabilité basée sur la blockchain, AI route optimisation and digital twins to improve efficiency and transparency.

Se préparer à la réglementation: Document critical tracking events for FSMA 204; pursue BRC or SQF certification; train staff on new protocols and compliance tools.

À propos du tempk

Tempk is a leading provider of cold chain solutions specialising in insulated packaging, temperature controlled containers and IoT enabled monitoring systems. Nous develop recyclable and reusable products to minimise environmental impact and help customers comply with stringent food safety regulations. Our research and development centre focuses on energy efficient designs and innovative materials that keep your products within strict temperature bands. With global distribution and a commitment to customer service, nous support clients across food, pharmaceutical and biotech industries in maintaining product integrity from origin to destination.

Étapes suivantes: Contact Tempk’s experts for a personalised cold chain assessment. Whether you need to transition to eco friendly packaging, optimise warehouse energy use or deploy smart sensors, our team can design a solution tailored to your business.