How to Prevent Dry Ice Bags from Exploding During Shipment?

Dry ice is crucial in the transportation of perishable goods, but improper handling can lead to dangerous situations, such as explosions. Dans cet article, we’ll explain why dry ice bags can explode when sealed, how pressure buildup occurs, and how to handle and package dry ice safely. By following 2025’s best practices, you can protect your goods and employees during transportation.

-

Why do dry ice bags explode when sealed?

-

How does pressure buildup lead to these explosions?

-

What are the best practices for safely sealing dry ice bags?

-

How can you prevent explosions during transportation?

-

Additional tips for safe dry ice handling in cold chain shipments.

Why Do Dry Ice Bags Explode When Sealed?

Glace sèche, la forme solide de dioxyde de carbone (Co₂), sublimates directly into a gas at -78.5°C (-109.3°F). This rapid transition from solid to gas causes a substantial volume of CO₂ to build up in a confined space. When dry ice is sealed inside an airtight bag or container, there’s no room for the gas to escape, leading to a dangerous increase in pressure.

The Science Behind Dry Ice Sublimation and Explosions

Dry ice releases about 0.8 cubic meters of CO₂ gas per kilogram as it sublimates. In a sealed container or bag, this gas expansion increases internal pressure exponentially. If the container cannot withstand this pressure, it will rupture, résultant en une explosion.

| Facteur | Sealed Dry Ice Bag | Unsealed Dry Ice Bag | Impact |

|---|---|---|---|

| Accumulation de pression | Oui | Non | Explosion risk in sealed bags |

| Ventilation | Aucun | Oui | Prevents pressure buildup |

| Container Integrity | May rupture | Remains intact | Safe transport with ventilation |

| Safety Risk | Haut | Faible | Reduced injury and damage risk |

How Does Pressure Build Up Inside a Sealed Dry Ice Bag?

Dry ice’s rapid sublimation produces CO₂ gas, which expands significantly in a confined environment. The more dry ice you pack in a sealed container, the more gas is released, leading to pressure accumulation. En plus, variations in temperature can cause this process to accelerate, surtout dans des environnements plus chauds, increasing the chances of an explosion if the container is not properly vented.

Factors Contributing to Pressure Build-Up:

-

Sealing the Bag Too Tightly: Preventing gas escape by sealing the bag too tightly accelerates pressure buildup.

-

Quantité de glace carbonique: More dry ice means more CO₂, raising the risk of pressure buildup.

-

Temperature Variations: Higher temperatures increase sublimation rates, speeding up the pressure buildup.

Best Practices for Safe Dry Ice Packaging

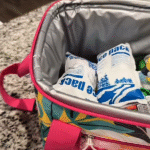

1. Use Ventilated Bags

Ventilated dry ice bags allow CO₂ gas to escape safely, Empêcher l'accumulation de pression. Always opt for bags with perforations or built-in ventilation systems.

2. Do Not Seal Dry Ice Bags Tightly

Leave some room for gas to escape. A loosely tied or partially sealed bag can allow the gas to vent safely, preventing an explosion.

3. Follow Manufacturer Guidelines

Manufacturers design dry ice bags with varying safety features. Be sure to follow the guidelines regarding how tightly to seal the bag and the maximum weight of dry ice.

4. Use Containers with Pressure Relief Valves

For shipments involving large quantities of dry ice, containers equipped with pressure relief valves are ideal. These valves release gas when pressure reaches dangerous levels, reducing the risk of explosion.

What Happens If a Dry Ice Bag Explodes?

Exploding dry ice bags pose several risks:

-

Physical Injury: Flying debris from the ruptured container can cause severe injury to handlers.

-

Asphyxation: Dans des espaces confinés, CO₂ gas can displace oxygen, conduisant à la suffocation.

-

Loss of Goods: Sensitive goods like pharmaceuticals or food may be destroyed by the explosion.

Safety Regulations for Dry Ice Transportation

Air Transport Regulations

When transporting dry ice by air, compliance with IATA regulations is essential to ensure safety. Some key rules include:

-

Limites de poids: Dry ice should not exceed 5.5 lbs (2.5 kg) per passenger in carry-on luggage and 2.5 kg in checked luggage.

-

Ventilation appropriée: Dry ice containers must allow gas to escape.

-

Exigences d'étiquetage: All dry ice shipments must be labeled with the UN 1845 marquage, indicating that the package contains dry ice.

2025 Trends and Future Directions in Cold Chain Logistics

As cold chain logistics continue to evolve, 2025 brings several key trends:

Emballage intelligent

IoT sensors and data loggers are increasingly used to monitor the internal conditions of dry ice shipments, ensuring that CO₂ gas does not exceed safe levels.

Durabilité

With a growing focus on sustainability, more companies are adopting alternative refrigerants like reusable gel packs and phase-change materials (PCMS) to reduce their reliance on dry ice.

Regulatory Updates

As global shipping regulations evolve, especially concerning air transport and hazardous materials, staying updated on current laws and best practices is critical for compliance.

What Are the Risks and Regulations for Shipping Dry Ice Bags?

Handling dry ice involves several inherent risks:

-

Explosion Hazard: If CO₂ gas builds up without venting, the container can explode.

-

Suffocation Hazard: CO₂ gas can displace oxygen in confined spaces, leading to asphyxiation.

-

Contact Hazard: Dry ice can cause severe frostbite upon direct skin contact.

To ensure safe transport:

-

Follow Packaging Requirements: Use vented containers, Assurer une bonne ventilation, and label packages correctly.

-

Train Personnel: Ensure all handlers are aware of the potential hazards and know how to act in case of an emergency.

-

Monitor Shipments: Use real-time data loggers to track the internal temperature and CO₂ levels during transportation.

Alternatives to Dry Ice for Safe Cooling

For shipments that don’t require ultra-cold temperatures, consider alternatives like packs de gel et PCMS, which are non-hazardous and easier to handle. These materials offer a safer and more sustainable solution for cold chain logistics.

| Méthode de refroidissement | Plage de température | Hazard Level | Mieux pour |

|---|---|---|---|

| Glace sèche | -78.5°C (marchandises surgelées) | Haut (explosion risk) | Aliments surgelés, vaccins |

| Packs de gel | 0°C (marchandises refroidies) | Faible | Aliments frais, médicaments |

| Packs PCM | Coutume (Par exemple, 5°C) | Faible | Pharmaceutiques de grande valeur, long-distance chilled shipments |

Conclusion: Safe Dry Ice Handling Best Practices

Principaux à retenir:

-

Prevent explosions by ensuring dry ice is stored in ventilated containers and never sealed tightly.

-

Follow safety regulations for transportation, including proper labeling and packaging guidelines.

-

Use alternatives like gel packs or PCM for non-freezing shipments to minimize hazards.

Étapes suivantes:

-

Always choose vented packaging.

-

Provide training on proper dry ice handling.

-

Regularly review and update your packaging and shipping procedures.

À propos du tempk

Tempk is an industry leader in cold chain packaging solutions. With over a decade of experience, we provide IATA-approved dry ice bags, PCM systems, and temperature-controlled containers designed to ensure safe and compliant transport of temperature-sensitive goods.

Besoin de conseils d'experts? Contactez Tempk dès aujourd'hui to explore how we can support your dry ice shipping needs.