Shipping meat with dry ice ensures that it remains frozen and of high quality during transport. Dans 2025, the cold chain logistics industry has seen significant advancements, making it more crucial than ever to understand the best practices for using dry ice in meat shipping. This article provides a comprehensive guide on how to efficiently pack and ship meat with dry ice, including the latest trends, packaging tips, and regulatory compliance guidelines to follow for optimal results.

-

What is dry ice and why is it ideal for meat shipping?

-

How much dry ice is needed to ship meat safely?

-

What are the best practices for packing meat with dry ice?

-

What are the regulatory and safety guidelines for dry ice shipments in 2025?

-

What are the eco-friendly alternatives to dry ice?

What Makes Dry Ice Ideal for Meat Shipping?

Glace sèche, la forme solide de dioxyde de carbone, sublimes at −78.5°C (−109,3 ° F), which is significantly colder than water ice. This ultra-low temperature makes it an effective cooling agent, perfect for keeping meat frozen throughout the shipping process. Contrairement à la glace ordinaire, la neige carbonique ne fond pas dans l'eau, preventing leaks and bacterial growth in the shipping container, thereby ensuring that the meat arrives in pristine condition.

Dry ice’s ability to sublimate directly from solid to gas without going through a liquid phase means no water residue is left to damage the packaging or contaminate the meat. This makes dry ice the ideal choice for shipping frozen meat over long distances, particularly for items like beef, volaille, and pork.

How Does Sublimation Protect Your Shipment?

Dry ice sublimates directly into carbon dioxide gas, which means there is no liquid phase. This eliminates the risk of leaks or soggy packaging that is often caused by melting ice. Cependant, it’s crucial to ensure proper ventilation within the shipping container to allow the gas to escape. If CO₂ gas builds up without a vent, it can create dangerous pressure, potentially damaging the packaging or causing it to explode.

To prevent this, packages containing dry ice should have venting channels or lids that are not sealed airtight. This will allow CO₂ to escape safely, similar to steam escaping from a kettle.

Benefits of Dry Ice Over Regular Ice for Meat Shipping

| Fonctionnalité | Paquet de glace sec | Glace ordinaire | Pourquoi ça compte |

|---|---|---|---|

| Operating Temperature | −78,5 ° C / −109°F | 0°C / 32°F | Keeps meat below freezing, preventing bacterial growth. |

| Changement de phase | Sublimer le gaz | Fond à liquide | Prevents leaks, dommages causés par l'humidité, and microbial growth. |

| Durée de refroidissement | 24+ heures | 3–4 hours | Longer-lasting cooling reduces the need for replacements. |

| Taste Impact | Food-grade CO₂ retains flavor | Meltwater can dilute flavors | Ensures meat retains its original taste. |

| Résidu | Pas d'humidité | Leaves water | Keeps packaging intact and prevents leaks. |

How Much Dry Ice Do You Need to Ship Meat?

Determining the right amount of dry ice depends on several factors, such as the size of the shipment, duration of transit, et les conditions environnementales.

Une règle générale est d'utiliser 5–10 lbs (2.3–4,5 kg) de glace sèche par 24 hours for every 10–15 lbs (4.5–6.8 kg) of frozen meat. Par exemple, expédition 5 kg (11 lbs) of meat for 48 heures would require around 12.7 lbs de glace sèche. Adjustments can be made based on the type of packaging, isolation, and the time of year (more dry ice may be needed during warmer months).

Dry Ice Estimation Formula for Frozen Meat

Here’s a simple formula to estimate your dry ice requirements:

base_per_24h = 7.5 # pounds per 24 hours (midrange)

hours = 48 # transit duration

box_factor = 1.0 # 1.0 for medium box, add 0.3 for large boxes

ambient_factor = 1.0 # 1.0 for normal conditions, add 0.3 for hot weatherBest Practices for Packing Meat with Dry Ice

Packing meat correctly with dry ice is crucial for ensuring it remains frozen and safe throughout transit. Here are the steps you should follow to optimize your packing process:

1. Choisissez le bon emballage

Use insulated containers like polystyrène élargi (PSE), polyuréthane (Pur), ou vacuum-insulated panels (VIP). VIP offers superior thermal performance, which is especially useful for longer shipments. These materials help minimize heat transfer and ensure your meat stays frozen for extended periods.

2. Properly Arrange Dry Ice and Meat

Placer une couche de glace sèche au fond du récipient, followed by the meat, and another layer of dry ice on top. This ensures even cooling throughout the shipment and prevents direct contact between the dry ice and the meat, which could cause freezer burn.

3. Fill Void Spaces

Use packing materials such as emballage de bulle ou crumpled kraft paper to fill any empty spaces in the container. This reduces airflow and helps maintain a consistent temperature throughout the shipment.

4. Vent the Container

As dry ice sublimates into gas, it’s essential to have small vent holes in the container to allow CO₂ to escape. Cela empêche l'accumulation de pression, which could damage the packaging or cause it to burst.

Regulatory Compliance and Labeling

Shipping meat with dry ice requires adherence to specific regulatory standards. Below are the key requirements:

-

Étiquetage: Clearly mark the package with “Dry Ice” or “Carbon dioxide, solide,” followed by Et 1845 and the net weight of dry ice in kilograms.

-

Classe de danger: Affix a Classe 9 hazardous material label to the package to comply with safety regulations.

-

Documentation: Pour les expéditions d'air, include the appropriate documentation, such as IATA PI 954 and DOT §173.217 regulations.

Carrier-Specific Requirements

Always verify the requirements with your carrier (Par exemple, FedEx, Hauts) for dry ice shipments. Each carrier may have specific instructions on packaging, étiquetage, and documentation.

Eco-Friendly Alternatives to Dry Ice

While dry ice remains the go-to solution for keeping meat frozen during long shipments, there are alternative cooling methods that may suit different shipping scenarios:

-

Packs de gel: Ideal for shorter shipments, these are water-based coolants that keep meat chilled, mais pas gelé.

-

Matériaux à changement de phase (PCMS): These materials absorb and release heat at specific temperatures, making them suitable for mid-range shipments where precise temperature control is required.

-

Refrigerated Containers: For bulk shipments, refrigerated containers offer a reliable method to keep meat cold throughout the entire transit process.

Conclusion

Shipping meat with dry ice is one of the safest and most reliable methods for ensuring it remains frozen during transport. By understanding the proper packing techniques, calculating the right amount of dry ice, and adhering to safety and regulatory guidelines, you can maintain the quality and safety of meat products throughout the shipping process.

Étapes suivantes:

-

Ensure your team is trained on dry ice handling and safety procedures.

-

Select the appropriate packaging and dry ice quantities for your shipments.

-

Always check and comply with regulatory guidelines to ensure safe and legal transport of perishable goods.

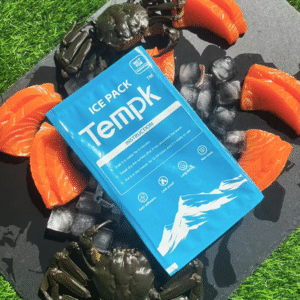

À propos du tempk

Tempk specializes in providing innovative cold chain logistics solutions for the meat industry. Our advanced packaging systems and real-time temperature monitoring services ensure that your products arrive at their destination safely and in optimal condition. Contact Tempk today to learn more about how we can help optimize your cold chain logistics for frozen meat.