Formation à la gestion de la chaîne du froid pharmaceutique: Pourquoi est-ce crucial pour votre entreprise?

Formation gestion de la chaîne du froid pharmaceutique est essentiel pour garantir le transport et le stockage corrects des produits sensibles à la température. Un système de chaîne du froid bien géré garantit la sécurité et l'efficacité des produits tels que les vaccins et les échantillons biologiques.. Dans cet article, nous explorerons pourquoi la formation est cruciale pour votre entreprise et comment elle impacte vos opérations.

-

Qu'est-ce que la formation à la gestion de la chaîne du froid pharmaceutique, et pourquoi est-ce vital?

-

Comment une formation adéquate peut-elle minimiser les risques associés à la logistique de la chaîne du froid pharmaceutique ??

-

Quels sont les éléments clés d’un programme de formation efficace sur la chaîne du froid?

-

Plus d’informations sur l’importance de la formation pour maintenir la conformité et garantir la sécurité des produits.

Qu'est-ce que la formation en gestion de la chaîne du froid pharmaceutique, et pourquoi est-ce vital?

La formation à la gestion de la chaîne du froid pharmaceutique est le processus consistant à éduquer les employés et les parties prenantes sur la manipulation des produits sensibles à la température tout au long de leur cycle de vie, de la production et du stockage au transport.. Cette formation garantit que les bonnes conditions de température sont maintenues pendant chaque phase, Empêcher la détérioration, contamination, ou dégradation des produits.

Une bonne formation est cruciale car:

-

La gestion de la chaîne du froid minimise les risques de compromettre la qualité du produit, surtout pour les produits biologiques, vaccins, et autres produits pharmaceutiques sensibles à la température.

-

La formation garantit la conformité réglementaire avec des normes comme les bonnes pratiques de distribution (PIB) et bonnes pratiques de fabrication (GMP), aider les entreprises à éviter les pénalités.

-

Il améliore la sécurité de l'utilisateur final, veiller à ce que les patients reçoivent des produits sûrs et efficaces.

Éléments clés d'un programme de formation en gestion de la chaîne du froid pharmaceutique

Un programme de formation efficace doit inclure les éléments suivants:

-

Comprendre la logistique de la chaîne du froid: Il s'agit de connaître les différentes étapes de la chaîne du froid et les risques associés à chacune d'entre elles..

-

Techniques de contrôle de la température: Former les employés sur l’importance de surveiller la température, y compris l'utilisation d'enregistreurs de données et de solutions d'emballage thermique.

-

Protocoles d'urgence: Les employés doivent savoir comment gérer les urgences telles que les écarts de température., pannes de courant, et les retards de transport.

-

Conformité réglementaire: Comprendre les réglementations mondiales et locales qui régissent la gestion de la chaîne du froid des produits pharmaceutiques.

| Composant | Description | Impact sur les opérations |

|---|---|---|

| Comprendre la logistique de la chaîne du froid | Enseigne le parcours des produits sensibles à la température | Améliore l’efficacité de la manipulation des produits |

| Techniques de contrôle de la température | Se concentre sur les méthodes de stockage et de transport appropriées | Réduit le risque de détérioration du produit |

| Protocoles d'urgence | Prépare le personnel aux excursions de température | Assure une réponse rapide aux problèmes critiques |

| Conformité réglementaire | Se concentre sur les réglementations et les normes de l'industrie | Maintient la conformité légale et évite les pénalités |

Conseils pratiques pour la mise en œuvre d’une formation à la gestion de la chaîne du froid

-

Tirez parti de scénarios réels: Utiliser des études de cas pour montrer comment une mauvaise gestion de la chaîne du froid a conduit à des rappels ou à des détériorations de produits..

-

Formation interactive: Créer des modules de formation attrayants qui permettent aux employés de simuler divers scénarios de chaîne du froid, comme la gestion d'une urgence ou la surveillance des températures à l'aide de technologies avancées.

-

Formation pratique: Offrir une formation pratique avec des équipements à température contrôlée pour garantir que les employés sont à l'aise avec les outils qu'ils rencontreront au travail.

Exemple du monde réel: Une entreprise pharmaceutique mondiale a mis en œuvre un programme complet de formation à la gestion de la chaîne du froid pour son équipe logistique. Par conséquent, ils ont réduit le nombre d'excursions de température des produits de 40% en première année du programme.

Pourquoi une formation adéquate sur la chaîne du froid est-elle cruciale pour minimiser les risques?

La logistique de la chaîne du froid pharmaceutique implique la manipulation de produits vulnérables aux changements de température. Un léger écart par rapport à la plage de température requise peut avoir de graves conséquences, comme une efficacité réduite, contamination, voire des effets secondaires néfastes pour l'utilisateur final.

Principaux risques minimisés par une formation appropriée:

-

Dégradation du produit: Sans manipulation appropriée, les produits sensibles comme les vaccins peuvent perdre leur efficacité, les rendant inefficaces.

-

Violations réglementaires: Une mauvaise manipulation de la chaîne du froid peut entraîner des amendes ou des rappels de la part des autorités sanitaires. Une formation adéquate garantit le respect des directives internationales, comme les recommandations de l’OMS sur le stockage des vaccins.

-

Confiance du client: La réputation d’une entreprise repose sur sa capacité à fournir des produits sûrs et efficaces. La formation permet de maintenir cette confiance en garantissant que les produits sont toujours livrés dans les meilleures conditions.

Gérer les excursions de température et les urgences

Les écarts de température constituent le risque le plus courant dans la logistique de la chaîne du froid. Un personnel correctement formé peut identifier ces problèmes rapidement et prendre des mesures correctives avant qu'un dommage ne survienne..

-

Surveiller la température en temps réel: Utilisez des dispositifs de surveillance en temps réel pour suivre la température des produits pendant le transport et le stockage.

-

Action immédiate: Si une excursion est détectée, le personnel doit connaître les mesures à prendre, comme identifier la source du problème, prendre des mesures correctives, et informer les parties prenantes concernées.

Conformité réglementaire et son rôle dans la formation

L'industrie pharmaceutique est fortement réglementée, et le maintien du respect de ces réglementations est essentiel. Les programmes de formation doivent couvrir les réglementations et normes suivantes:

-

Bonne pratique de distribution (PIB): GDP garantit que les produits pharmaceutiques sont stockés de manière cohérente, transporté, et manipulé dans des conditions appropriées.

-

Bonnes pratiques de fabrication (GMP): Cette directive garantit que les produits pharmaceutiques sont systématiquement produits et contrôlés conformément aux normes de qualité..

-

Organisation Mondiale de la Santé (OMS) Lignes directrices: L'OMS définit des exigences spécifiques en matière de température pour les vaccins et autres produits sensibles, qui doit être suivi pour éviter la détérioration.

Dernières tendances et développements dans la gestion de la chaîne du froid pharmaceutique

Dans 2025, la gestion de la chaîne du froid pharmaceutique évolue avec les nouvelles technologies et les meilleures pratiques de l'industrie. Ces évolutions façonnent la manière dont les sociétés pharmaceutiques gèrent leur logistique et garantissent la sécurité de leurs produits..

Tendances émergentes:

-

Emballages intelligents et capteurs IoT: L’utilisation de solutions d’emballage intelligentes se développe. Ces systèmes comprennent des capteurs de température et d'humidité qui transmettent des données en temps réel aux plateformes de surveillance..

-

Analyse prédictive alimentée par l'IA: Intelligence artificielle (IA) est de plus en plus utilisé pour prédire les fluctuations ou les risques potentiels de température, permettre aux entreprises de prendre des mesures préventives avant que des problèmes ne surviennent.

Nouvelles technologies ayant un impact sur la gestion de la chaîne du froid

-

Dispositifs de surveillance de la chaîne du froid: Des enregistreurs de température et des appareils GPS innovants sont utilisés pour suivre les expéditions de produits en temps réel.

-

Blockchain pour la transparence: La technologie Blockchain est à l'étude pour garantir l'intégrité des expéditions pharmaceutiques en fournissant un système transparent, enregistrement infalsifiable du mouvement du produit.

-

Intelligence artificielle pour la gestion des risques: L'IA peut analyser les données des systèmes de surveillance de la chaîne du froid pour prédire et atténuer les risques potentiels avant qu'ils ne surviennent.

FAQ

Quelle est l’importance de la formation à la gestion de la chaîne du froid pour les entreprises pharmaceutiques?

La formation à la gestion de la chaîne du froid est essentielle pour garantir que les produits sensibles à la température sont manipulés correctement, réduire les risques de dégradation des produits et assurer le respect de la réglementation.

Comment la formation sur la chaîne du froid peut-elle aider à minimiser les risques pendant le transport?

Une formation adéquate sur la chaîne du froid apprend au personnel à surveiller les températures en temps réel et à agir rapidement en cas d'excursion de température., minimiser les risques de détérioration du produit.

Conclusion et informations exploitables

En conclusion, la formation à la gestion de la chaîne du froid pharmaceutique est un investissement qui garantit l'intégrité, sécurité, et l'efficacité des produits tout au long de leur cycle de vie. En sensibilisant le personnel aux bonnes pratiques de manipulation des produits sensibles à la température, les entreprises peuvent réduire les risques, maintenir la conformité, et bâtir la confiance des clients.

Étapes exploitables:

-

Développer un programme de formation sur la chaîne du froid sur mesure basé sur les besoins uniques de votre entreprise.

-

Investissez dans la dernière technologie pour la surveillance de la température en temps réel.

-

Mettre régulièrement à jour les supports de formation pour refléter les dernières modifications réglementaires et les avancées technologiques.

En prenant ces mesures, les sociétés pharmaceutiques peuvent améliorer leurs systèmes de gestion de la chaîne du froid et garantir que leurs produits répondent toujours aux normes de sécurité et de qualité les plus élevées.

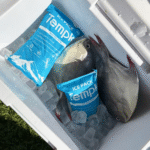

À propos du tempk

Tempk est spécialisé dans les solutions avancées de chaîne du froid adaptées à l'industrie pharmaceutique. Nos produits, y compris des systèmes intelligents de surveillance de la température, assurez-vous que vos produits sensibles à la température sont stockés et transportés en toute sécurité, répondant aux exigences réglementaires les plus strictes.

Contactez-nous aujourd'hui pour une consultation sur l’amélioration de votre logistique sous chaîne du froid.