What Are Dry Ice Alternative Dry Ice Packs and How Do They Work?

In the cold chain industry you often hear dry ice alternative dry ice packs mentioned when discussing safer and greener ways to keep shipments cold. Traditional dry ice is frozen carbon dioxide that sublimates at −78.5 °C and requires hazardous material labels and safety training. By contrast, dry ice alternative packs use Matériaux à changement de phase (PCMS) or non toxic gels to deliver sustained cooling at specific temperatures without the extreme cold and regulatory hurdles. You might choose them to protect pharmaceuticals, food or biologics while reducing risk, waste and carbon emissions. This guide explains the science behind these alternatives, compares options, outlines safety tips and explores 2025 innovations to help you make informed shipping decisions.

Why consider alternatives? Dry ice sublimates quickly and is a hazardous material; alternatives like PCMs and gel packs avoid frostbite risks while offering more precise temperature control.

What types exist? Explore PCMs in hard bottles, blankets, pochettes, microcapsules, foams and gel pack hybrids.

How do alternatives compare to dry ice? Understand temperature ranges, durée, reusability and cost differences across PCMs, packs de gel, vacuum insulated panels and hybrid systems.

Which option is right for you? Learn decision factors such as product sensitivity, temps de transit, regulations and sustainability goals.

Quoi de neuf 2025? Discover trends like reusable packaging growth, bio based insulation, IoT sensors and multi temperature hybrid solutions that shape the future of cold chain logistics.

Why consider dry ice alternative dry ice packs for shipping?

Dry ice is extremely cold and hazardous, making it suitable only for ultra cold shipments. It sublimates directly from solid to gas and requires venting; contact can cause frostbite, and enclosed sublimation can displace oxygen. Carriers classify it as a hazardous material with strict labeling, quantity limits and training requirements. En outre, dry ice supplies have fluctuated recently, and it typically lasts just 12–24 hours in insulated containers.

Alternatives mitigate these drawbacks by using phase change technologie. PCMs and gel packs freeze and melt at engineered temperatures, absorbing heat during melting and releasing it during freezing. They provide controlled cooling at ranges like 2–8 °C or –20 °C for days and can be reused many times. They are classified as non hazardous, avoiding complex shipping rules and reducing risk to handlers. Choosing an alternative lets you balance safety, compliance and sustainability while still protecting your cargo.

Real world context

Picture shipping vaccines from California to Europe. Using dry ice means scheduling refills, labeling packages as dangerous goods and training staff on ventilation. An alternative pack engineered to freeze at 2–8 °C maintains the same range for up to 72 hours without venting. It avoids hazardous labels, simplifies customs clearance and can be reused multiple times, saving money and reducing waste.

What types of dry ice alternative dry ice packs are available?

Dry ice alternatives fall into several categories: Matériaux à changement de phase, packs de gel, panneaux isolés sous vide et eco friendly insulation. Each category offers unique features that allow you to tailor cooling to your shipment’s needs. The following sections break down how these technologies work and what differentiates them.

Phase change material packs: precise temperature control and reusability

PCMs undergo a reversible phase transition between solid and liquid states at a specific temperature. When melting, they absorb heat and keep the inside of the package cool; when freezing, they release heat and prevent over cooling. Because of this “latent heat” effect, PCMs maintain a narrow temperature range for extended periods. Their versatility comes from the wide variety of formulations and packaging formats available:

| PCM Format | Description | Typical Temperature Ranges | Avantage pratique |

| Hard bottle PCMs | Rigid containers filled with paraffin wax, fatty acids or salt hydrates | Custom ranges such as 2–8 °C or –20 °C | Easy handling and durability for repeated use |

| Blanket PCMs | Flexible sheets impregnated with PCMs, cut to fit packages | Moderate ranges like 2–15 °C | Conform to irregular shapes and provide even coverage |

| Soft pouch PCMs | Pouches containing paraffin wax, salt hydrates or glycols | 0–8 °C or –20 °C | Flexibility for tight spaces and mould able placement |

| Microencapsulated PCMs | Tiny droplets of PCM encased in polymer shells | Wide range; can be embedded into fabrics | High surface area for efficient heat transfer |

| Foam PCMs | Foam material impregnated with PCM | Versatile ranges depending on formulation | Combines insulation and cooling in one |

| Gel pack PCMs | Gel packs containing PCMs like salt hydrates | 0–8 °C or –20 °C | Familiar form factor; improved performance over standard gel packs |

| Brick/Block PCMs | Solid blocks used in construction or bulk storage | Personnalisable | Bulk thermal storage for large shipments |

Avantages: PCMs provide precise temperature control, durée de refroidissement prolongée, reusability and environmental friendliness. They consume no energy during transit, making them ideal for long distance shipments or control room temperature environments. Systems like Mercury’s CCT Advanced™ SU96 combine PCMs with vacuum insulated panels to maintain 2–8 °C for up to 144 hours and can be reused 50 fois.

Défis: Initial costs are higher than gel packs or dry ice, and some PCMs may suffer from supercooling or phase separation. Specialized encapsulation may be needed to prevent leaks and maintain chemical stability.

Packs de gel: simple yet limited cooling

Standard gel packs are pouches filled with water based gel that freeze around 0 °C. They are widely used for food deliveries and short distance shipments due to their affordability and ease of use. Some manufacturers incorporate PCMs into gel formulations to extend their temperature range to –10 °C or –20 °C.

Pros:

Reusability and affordability – Gel packs can be refrozen and reused multiple times. They cost less than specialized PCMs and are readily available.

Non toxicity and safety – Because they use food grade gels, they pose no hazard if punctured and don’t produce CO₂ gas. This makes them easy for consumers to handle.

Inconvénients:

Limited temperature control – Gel packs typically maintain temperatures around 0 °C; even PCM enhanced gels are only effective down to –20 °C. They may not keep goods fully frozen over long durations.

Shorter duration and weight – Gel packs melt faster than PCMs and add significant weight to shipments, which increases costs. They usually remain cold for 12 hours or less if the insulation isn’t optimal.

Gel packs shine in last mile deliveries of fresh produce, meal kits and beverages where moderate cooling and low cost matter more than long durations. For extended journeys or frozen goods, you may need to pair them with PCMs or dry ice.

Vacuum insulated panels and hybrid systems: extended duration and reduced dry ice

Vacuum insulated panels (Vips) are rigid panels with a vacuum core that dramatically slows heat transfer. When paired with PCMs or a small amount of dry ice, VIPs offer long duration cold shipping. Mercury’s CCT Advanced™ SU96 combines VIPs with PCM gels to maintain 2–8 °C for up to 144 hours while reducing container size and weight by up to 50%. The system includes a hibernation feature that keeps products within range during transit delays.

Another hybrid, le Crēdo Cube™ Dry Ice container, integrates VIP insulation and PCMs to keep cargo below –60 °C for 96–156 hours. The VIPs reduce dry ice sublimation by up to 75%, minimizing re icing and hazardous material handling. Because the containers are reusable for five years, they lower long term costs and waste.

Active systems tel que NanoCool™ use evaporative cooling and PCMs to deliver cooling up to seven times more efficient than gel packs. They maintain 2–8 °C for 48–92 hours depending on configuration. Although the lid is single use, the VIP body can be reused, balancing performance and sustainability.

Eco friendly insulation and bio based materials

Sustainable packaging is gaining momentum. Wool liners and biodegradable foam reduce reliance on expanded polystyrene and provide good insulation. Closed loop models like crate pooling allow containers to circulate between suppliers and customers, minimizing waste. Bio based PCMs derived from vegetable oils or dairy proteins offer lower environmental impact while maintaining thermal efficiency. Combining these materials with reusable PCMs or gel packs supports corporate ESG goals and reduces carbon footprint.

How do phase change materials compare to dry ice?

When evaluating dry ice alternatives, you need to understand how PCMs and dry ice differ in temperature range, durée, handling and cost. Dry ice maintains ultra cold temperatures below –70 °C and is indispensable for shipments requiring deep freezing. It sublimates without leaving liquid residue but lasts only 12–24 hours and requires ventilation and hazardous labels.

PCMS, d'autre part, can be engineered to freeze at 2–8 °C, –20 °C or other ranges to keep pharmaceuticals or biologics refrigerated without risk of freezing. They offer precise temperature control and maintain conditions for multiple days. Because they are non hazardous, they avoid compliance burdens and can be reused hundreds of times. Cependant, they have a narrower temperature spectrum and may not reach ultra cold levels; some formulations suffer from supercooling or phase separation.

For shipments requiring –70 °C or colder (Par exemple, certain mRNA vaccines), dry ice remains the only practical option. For goods that need moderate cooling or refrigeration, PCMs provide better control and sustainability. Many logistics providers adopt hybrid systems that combine a small amount of dry ice with PCM panels. This approach extends cooling while minimizing hazardous handling.

Are gel packs effective dry ice alternatives?

Gel packs serve as a simple entry point into dry ice alternatives. They are best suited for short routes or shipments that need to remain just below 0 °C. When used appropriately, gel packs can maintain below freezing temperatures for up to 24 heures, especially when preconditioned and paired with insulation. Manufacturers now offer “hydrate dry ice packs” ou PCM enhanced gel packs that mimic dry ice performance at –20 °C without hazardous handling.

Yet gel packs alone aren’t sufficient for long haul or ultra cold applications. They melt relatively quickly and add significant weight. Pour les expéditions dépassant 24 hours or requiring deep freezing, gel packs should be combined with PCMs or VIPs to achieve longer durations. Hybrid packs help maintain different temperature zones, such as refrigerated and frozen areas in the same container.

What about vacuum insulated panels and hybrid solutions?

Vacuum insulated panels revolutionize cold chain packaging by dramatically reducing heat transfer. When used with PCMs or minimal dry ice, they enable shipping durations previously unattainable with gel packs alone. Mercury’s CCT Advanced™ SU96 uses VIPs to sustain 2–8 °C for up to 144 hours and reduces container size and weight by up to 50%. The Crēdo Cube™ container keeps cargo below –60 °C for 96–156 hours while cutting dry ice consumption by 75%. Active systems like NanoCool™ deliver seven fold efficiency improvement over gel packs and maintain temperature for 48–92 hours.

Hybrid strategies often pair PCMs with a small amount of dry ice. This combination provides an initial burst of ultra cold temperature from the dry ice and sustained cooling from the PCM once the dry ice sublimates. It’s ideal for shipments requiring both deep freezing and refrigeration, such as a vaccine kit containing ultra cold components and supporting documentation at controlled room temperature.

How to choose the right ice substitute for your shipment?

Selecting the best dry ice alternative involves balancing product requirements, durée du transit, regulatory constraints and sustainability goals. The following considerations help you decide:

Temperature requirements – Determine the temperature range your product needs. Glace sèche (< –70 °C) is irreplaceable for deep frozen goods like CRISPR reagents. Pour les produits réfrigérés, choose PCMs engineered for 2–8 °C or –20 °C. Gel packs work for 0–10 °C shipments but may not maintain freezing.

Shipment duration and distance – PCMs and hybrid systems can sustain 24–72 hour shipments. VIP based solutions like the SU96 extend this to 144 heures. For longer routes or harsh climates, consider adding more PCM panels or mixing with a bit of dry ice.

Regulatory complexity and safety – Dry ice requires hazardous material documentation, weight limits and vented containers. PCMs and gel packs are non hazardous, simplifying shipping and reducing training costs. If shipping internationally, non hazardous alternatives avoid customs delays.

Coût et durabilité – Gel packs are inexpensive and widely available, but they generate more waste and weight. PCMs have higher upfront costs but are reusable hundreds of times, lowering total cost of ownership. Dry ice incurs recurring costs and CO₂ emissions and must be replenished for each shipment. Evaluate life cycle costs and your company’s environmental goals.

Packaging integration – Use quality insulation, such as VIPs or thick foam liners, to slow heat transfer. Choose containers sized to your payload to minimize air pockets. Follow manufacturer pack out protocols to ensure consistent performance.

Customer experience and disposal – Dry ice can be intimidating and requires special disposal instructions. Gel packs and PCMs are easy to reuse or recycle. Provide a card instructing end users on safe handling and encourage them to reuse or recycle the packs.

Decision tool: self assessment

Use the following questions to assess your needs:

Product sensitivity – Does your product need to stay frozen solid or merely refrigerated? If it requires deep freeze, choose dry ice or a hybrid with dry ice; sinon, PCMs or gel packs will suffice.

Temps de transit – How long will the shipment be in transit? For under 24 heures, gel packs may be enough; for 48–144 hours, PCMs with VIPs or hybrid systems are safer.

Compliance tolerance – Are you prepared to handle hazardous labels and training? If not, avoid dry ice and opt for non hazardous alternatives.

Budget and sustainability priorities – Balance initial cost with reuse potential and environmental impact. PCMs may cost more upfront but provide long term savings and reduce waste.

Flexibilité – Do you need multiple temperature zones in one package? Hybrid solutions combining PCMs of different phase points, gel packs and small dry ice amounts can provide both frozen and chilled compartments.

What are the safety and regulatory considerations?

Regardless of the cooling medium, safety is paramount. Handling dry ice requires personal protective equipment like insulated gloves, goggles and a face shield. Always store and transport dry ice in well ventilated areas to prevent CO₂ buildup, and never place it in sealed containers. Dispose of unused dry ice by letting it sublimate in an open area. Follow carrier regulations: label shipments with the weight of dry ice and hazard markings, and adhere to airline and ground transport limits.

Handling gel packs and PCMs is generally safer. Inspect packs for punctures before use and precondition them according to manufacturer guidelines. Encourage customers to recycle or reuse packs and clean them between uses. For shipments containing PCMs in sealed panels, ensure the container design accommodates volume changes during phase transitions to prevent leaks. Train staff on correct pack out procedures and emergency steps for handling dry ice incidents or gel leaks.

2025 trends in dry ice alternative packaging and innovation

The cold chain industry is evolving rapidly to meet sustainability goals, regulatory changes and the demands of biologics. Here are the key trends shaping the future:

Sustainable and circular packaging

Reusable packaging is surging. Market research shows that the global reusable cold chain packaging market could grow from USD 4.97 milliards en 2025 en USD 9.13 milliards 2034 at a 6.98% compound annual growth rate. Companies are moving away from single use EPS toward recyclable and biodegradable materials. Bio foam and wool liners are gaining popularity for their low environmental impact and good insulation. Bio based PCMs derived from vegetable oils and dairy proteins reduce carbon footprints while maintaining performance.

Smart and active packaging

Internet des objets (IoT) sensors are increasingly embedded in cold chain containers. Modern reusable boxes use Bluetooth Low Energy, NFC and GPS to monitor temperature, humidité et localisation en temps réel. Self refrigerated smart boxes like the Ember Cube maintain 2–8 °C for over 72 hours using battery power and stream live data, improving compliance with regulations such as 21 Partie CFR 11. Active packaging components—antimicrobial films, oxygen scavengers and thermochromic inks—extend shelf life and provide visual indicators of temperature excursions.

Material and insulation innovation

Research is optimizing PCMs and VIPs for better performance and lower weight. Bio based PCMs harness vegetable oils or dairy proteins; vacuum insulated panels are becoming thinner, freeing up payload space. Reusable gel packs are redesigned to reduce weight and improve recyclability.

Self refrigerated containers

Battery powered units maintain precise temperatures without external ice substitutes. These containers keep products at 2–8 °C for 48–72+ hours and include built in sensors. Though costly, they support multiple shipments and ensure digital records for compliance.

Multi temperature and hybrid solutions

The newest shippers can carry products requiring different temperature zones in one box. They may combine PCMs set to various phase points or mix PCMs with dry ice to create both chilled and frozen compartments. This flexibility helps logistics providers consolidate shipments and cut emissions.

Questions fréquemment posées

Q1: How long do dry ice alternative dry ice packs last?

Duration depends on the type and insulation. PCM based packs typically maintain 2–8 °C or –20 °C for 24–72 heures, while VIP based systems like CCT Advanced™ SU96 extend that to 144 heures. Gel packs alone may only last 12 heures ou moins without high quality insulation.

Q2: Are dry ice alternatives safe for shipping vaccines?

Oui. PCMs engineered for 2–8 °C or –20 °C maintain the precise temperature ranges required for vaccines and biologics. They are non hazardous and avoid the risk of product freezing. Always follow manufacturer guidelines for preconditioning and insulation.

Q3: Can gel packs replace dry ice for frozen food?

Only for short trips. Gel packs generally keep products near 0 °C and may not maintain deep freeze conditions. For frozen food shipped over longer distances, use PCM packs engineered for –20 °C or hybrid systems that include a small amount of dry ice.

Q4: What is the environmental impact of dry ice alternatives?

PCMs and gel packs are non hazardous and reusable. PCMs may be reused hundreds of times, Réduire les déchets. Bio based PCMs and wool insulation further cut carbon footprints. Dry ice production emits CO₂ and requires new product for each shipment.

Q5: How do I dispose of dry ice and ice substitute packs?

Allow unused dry ice to sublimate in a well ventilated area; never discard it in trash or sinks. For gel packs and PCMs, check local recycling guidelines and encourage customers to reuse them. Clean and inspect packs between uses for hygiene and safety.

Résumé et étapes suivantes

Dry ice alternatives such as PCMs, gel packs and VIP based hybrid systems offer plus sûr, more sustainable and often more cost effective cooling solutions than dry ice. PCMs provide precise temperature control, extended duration and reusability. Gel packs are affordable and easy to use but limited in duration and temperature range. Vacuum insulated panels and hybrid systems combine the best of both worlds, extending cooling to 96–144 hours while reducing hazardous material handling. When choosing a solution, consider temperature requirements, durée du transit, regulatory complexity, cost and sustainability goals. Follow safety guidelines for handling and disposing of dry ice and alternatives.

Plan d'action:

Assess your product’s temperature sensitivity and transit time.

Select a cooling method (PCM, gel, hybrid or dry ice) based on the criteria outlined above.

Invest in high quality insulation like VIPs or bio based foam to maximize performance.

Develop clear packing protocols and train staff on handling and safety.

Monitor shipments using IoT sensors and refine your strategy based on data.

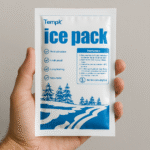

À propos Rotation

Tempk is a provider of innovative cold chain packaging solutions. We focus on durable, reusable cold chain products, including phase change material packs, vacuum insulated containers and eco friendly insulation. Our products are validated to maintain precise temperature ranges for pharmaceuticals, food and biologics. We continuously innovate with bio based materials and smart packaging technologies to reduce carbon footprint and improve shipment visibility. Nous invite you to explore our range of customizable solutions and consult our experts for tailored recommendations.

Appel à l'action: Contact Tempk today for a free consultation on transitioning from traditional dry ice to sustainable alternatives. Our team will assess your shipping needs and propose the most efficient and eco friendly cooling solution.