Que se passe-t-il si un sac de glace carbonique est mouillé? Sécurité & Correctifs

Quand un dry ice bag gets wet, poussées de sublimation, Le gaz CO₂ s’accumule plus rapidement, et le temps d'attente diminue. Si un sac de glace carbonique est mouillé à l’intérieur d’un expéditeur scellé, la pression peut augmenter et créer des risques pour la sécurité. Il te faut vite, des étapes simples qui stabilisent la température, maintenir la conformité, et assurer la sécurité des personnes. Un kilogramme de neige carbonique produit environ 541 L de gaz CO₂, donc la ventilation n'est pas négociable.

-

Pourquoi un sac de glace carbonique est mouillé et que se passe-t-il ensuite (condensation et transfert de chaleur)

-

How to fix the situation when a dry ice bag gets wet in transit

-

How to prevent wet dry ice bag events with better packaging and design

-

2025 materials and sensors that reduce moisture risk

Why does a dry ice bag get wet—and what happens next?

Réponse courte: L'eau est une autoroute thermique — lorsqu'un sac de glace carbonique est mouillé, sublimation accelerates.

Condensation forms as warm, humid air meets a cold surface. If liquid water touches dry ice, heat transfer increases dramatically and CO₂ release spikes. Expect faster fogging, shorter cooling duration, and higher internal pressure if vents are blocked.

Moisture on the film or in the cavity turns into a heat bridge. You’ll see sweating, frost crusting, and labels loosening. In sealed liners, pressure rises as CO₂ accumulates. Dans des espaces confinés, that gas can displace oxygen — always keep the area ventilated.

How much CO₂ is released when a dry ice bag gets wet?

A dry ice bag that gets wet releases CO₂ much faster.

1 lb of dry ice generates about 250 L of CO₂; 1 kg generates ~541 L. That can deform packaging or pop seams if a liner is sealed. Use vent-able folds or micro-perforations; never knot or heat-seal a liner.

| Exposure scenario | Estimated rate | Risk level | Impact on shipment |

|---|---|---|---|

| Sec, well-vented | Lent | Faible | Predictable hold time |

| Humid air | Modéré | Moyen | Slightly shorter cooling duration |

| Direct water contact | Le plus rapide | Haut | Pressure build-up and temperature loss |

Practical tips when a dry ice bag gets wet

-

Si à l'intérieur: Move to a ventilated area; open liner folds; wipe moisture; replace soggy inserts.

-

During loading: Add a vapor barrier around the payload and ensure the ice compartment can vent.

-

If frequent: Add splash shields or use higher-grade insulation designed for humid lanes.

Exemple de cas: A pharmaceutical lab found that replacing unlined bags with moisture-resistant composite liners extended temperature hold time by 24 hours on 72-hour routes.

What should you do if a dry ice bag gets wet in transit?

Act fast: ventiler, verify vent paths, remove water, replace wet components, and document for compliance.

Your goal is to restore thermal performance and maintain safety.

-

Aérer la zone — CO₂ is heavier than air.

-

Vérifier la ventilation — never seal dry ice in an airtight liner.

-

Remove free water — wipe surfaces dry.

-

Replace insulation — wet fibers conduct heat rapidly.

-

Re-label — use freezer-grade materials.

-

Record details — time, emplacement, and corrective actions.

| Étape | Raison | Time needed | Avantage |

|---|---|---|---|

| Ventilation | Prevents gas buildup | 1–2 minutes | La sécurité avant tout |

| Verify venting | Avoids liner rupture | 1 min | Conformité |

| Remove moisture | Reduces heat transfer | 3 min | Longer cooling |

| Replace inserts | Restores insulation | 5 min | Stable temperature |

How to prevent a “dry ice bag gets wet” scenario

Contrôler l'humidité, pre-condition packaging, and design for venting.

Maintain packing rooms below 40% RH, pre-chill shippers, and use hydrophobic liners. Avoid over-packing — leave vent space above the refrigerant.

| Prevention Tip | Méthode | Résultat |

|---|---|---|

| Contrôle de l'humidité | Dehumidify pack-out rooms | Less condensation |

| Pre-conditioning | Cool boxes before loading | Reduces dew formation |

| Liner upgrade | Use hydrophobic multi-layer film | Stops direct moisture |

| Ventilation adéquate | Pli, Ne sceller pas, liner tops | Prevents over-pressure |

2025 developments and trends that matter

New packaging technologies make it easier to prevent moisture damage. Smart CO₂ and humidity sensors can detect when a dry ice bag gets wet before it compromises hold time. VIP shippers and closed-loop containers extend cold retention and minimize waste.

Latest innovations

-

Sensor-integrated packaging – sends alerts when humidity or CO₂ levels rise

-

Hydrophobic liners – repel water without trapping gas

-

Systèmes réutilisables – lower waste and maintain consistent performance

Perspicacité du marché: Global adoption of smart and sustainable cold-chain solutions is increasing as compliance and efficiency pressures grow.

FAQ

Is it dangerous if a dry ice bag gets wet?

Oui. Faster CO₂ release can displace oxygen and create pressure. Keep packages vented.

Why does fog appear when a dry ice bag gets wet?

Heat from water drives rapid sublimation, and the gas condenses moisture in the air.

Can I reuse a liner after it gets wet and freezes?

Only if it hasn’t cracked and still vents safely.

Should I seal a wet liner to keep water out?

Non. Leave venting open — seal moisture out at the payload level instead.

How much gas is produced?

À propos 250 L per pound, ou 541 L per kilogram of dry ice.

Résumé et recommandations

When a dry ice bag gets wet, sublimation speeds up, CO₂ rises, and insulation efficiency drops.

Vent immediately, verify vent paths, remove moisture, and replace damaged parts.

Prevent recurrence through humidity control, better liner materials, et formation.

Étapes suivantes:

Audit your SOPs, upgrade to moisture-resistant liners, and test CO₂ sensors on humid routes.

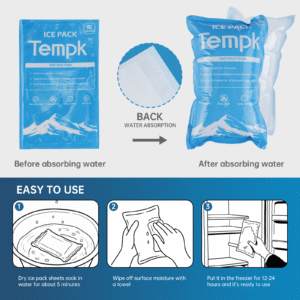

Need tailored solutions? Consult a Tempk specialist for a packaging audit.

À propos du tempk

Tempk designs and tests cold-chain packaging that stays compliant and reliable — even when conditions get wet.

Our team blends packaging science with logistics experience to extend hold times and meet 2025 normes réglementaires.

We help global clients reduce spoilage, improve safety, and achieve sustainable temperature control.