Description du produit

Détail du produit

Rugged reusable shipper design for repeated cold chain cycles, reducing damage risk in handling and line-haul.

PU insulation core supports long hold times; rigid PU foams are widely used as high-efficiency insulation due to low thermal conductivity. (PMC)

Large internal payload for consolidated cases, seafood totes, frozen food packs, or e-commerce master cartons.

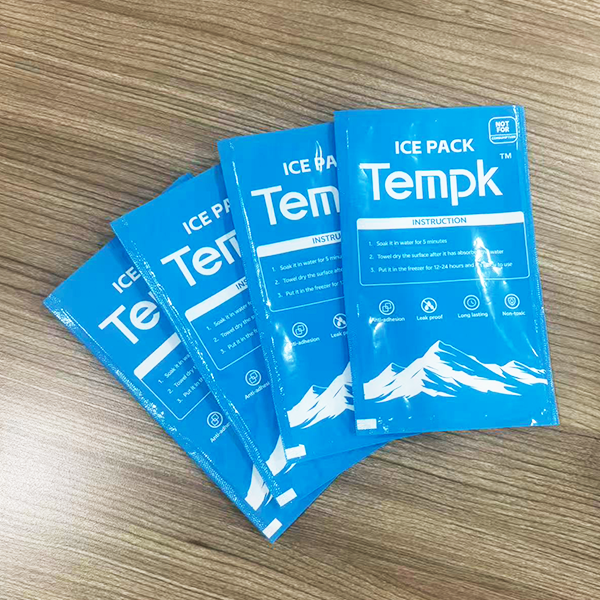

Compatible with common cold chain pack-outs (packs de gel, PCM, briques de glace) and optional identification (labels/QR/RFID).

Vidéo du produit

Détails de la fonction

Designed to reduce ambient heat gain and maintain temperature stability through staging, chargement, and transit.

Suitable for transporting fresh and frozen foods (viande, fruit de mer, laitier, Repas surgelés, glace, produire) in distribution and last-mile operations.

Can be configured for pharma/biotech lanes when used with qualified refrigerants and temperature monitoring (data logger/indicator).

Supports reverse logistics workflows: réutilisable, nettoyable, and operationally consistent for fleet deployment.

Instructions

Load product to minimize empty headspace; place refrigerants to control heat flow (top/side/bottom) based on lane risk.

Add a temperature logger for auditability when required by the shipment specification.

Après livraison, faire le ménage, sec, and inspect; rotate assets through maintenance to keep performance consistent.

Caractéristiques

PE outer shell + PU insulation core + PS inner liner

High payload capacity for bulk distribution

Réutilisable, easy to sanitize for multi-trip programs

Works with standard gel packs / PCM for validated pack-outs

Suitable for cross-dock, line-haul, and multi-drop delivery