Pengiriman Ekspres Terkendali Suhu yang Terjangkau?

Terjangkau temperature-controlled express delivery is possible when you stop paying for “speed everywhere” and start paying for “control where it matters.” You cut cost by controlling packaging, desain jalur, waktu di ambang pintu, dan kegagalan—bukan dengan mencari biaya kurir yang lebih rendah. Diperbarui Desember 19, 2025, panduan ini memberi Anda sistem praktis yang dapat Anda ulangi dalam skala besar.

Artikel ini akan menjawabnya untuk Anda:

- How to define “affordable” using biaya per pengiriman yang berhasil

- How to choose lane tiers that match your doorstep reality

- How to right-size packaging to cut cost Dan reduce temperature risk

- How to stop coolant overspend with a Two Buffers rencana

- How to build SOPs, KPI, and proof without turning it into a tech project

What does “affordable temperature-controlled express delivery” really mean?

Pengiriman ekspres dengan pengatur suhu yang terjangkau berarti total biaya terendah untuk pengiriman dalam jangkauan, hasil tepat waktu—bukan harga pengiriman item baris terendah. Biaya Anda yang sebenarnya sudah termasuk pengemasan, tenaga kerja, tiket dukungan, dan pengembalian dana setelah kegagalan. When a “cheap” lane fails, you pay twice: once to ship, and again to fix it.

A helpful mindset is to treat affordability like a leaky bucket. If you only patch the “carrier rate” hole, money still leaks out through reships and complaints. You win when you make the process boring and repeatable.

Cost-per-successful-delivery (the truth metric)

Use this simple KPI to keep decisions honest:

| Metrik | Apa yang Anda lacak | Mengapa itu penting | Apa artinya bagimu |

|---|---|---|---|

| Biaya per pengiriman | kurir + kemasan + tenaga kerja | easy to budget | not the full truth |

| Success rate | % in-range and on-time | shows reliability | exposes weak lanes |

| Cost per successful delivery | total cost ÷ success rate | outcome-based | real affordability |

Kasus dunia nyata: Teams often lower total spend by improving success rate first, then cutting waste second.

Tip dan saran praktis

- Fix success rate first: reliability gains often beat small material cuts.

- Cut waste second: right-size packaging once the lane is stable.

- Track weekly: affordability improves fastest when you watch it often.

How do you know if affordable temperature-controlled express delivery is realistic for you?

Affordable temperature-controlled express delivery is realistic when you can measure outcomes, tier your lanes, and control dwell time. If your last mile is chaotic, cost spikes and failures hide until refunds pile up. Some studies estimate last-mile cost can be a large share of total delivery/logistics spend, which is why it must be designed, not hoped for.

Use this quick self-test to see your current state. It’s short on purpose so you actually use it.

Tes mandiri interaktif: The Affordability Score (0–10)

Berikan setiap item 0 (TIDAK), 1 (partial), 2 (Ya). Jumlah 0–10.

- Do you know your cost per successful temperature-controlled delivery?

- Apakah kamu punya service tiers for different risk levels?

- Do you validate packaging on real lanes (musim panas dan musim dingin)?

- Do you control last-mile dwell time (pusat, mobil van, ambang pintu)?

- Do you review exceptions weekly and change one process at a time?

Bagaimana menafsirkannya:

- 0–3: Build basics before you expand.

- 4–7: Pilot tiering and sampling to lower cost per success.

- 8–10: You’re ready to scale with data-led negotiations.

Tip dan saran praktis

- Jika Anda mencetak gol 0–3, freeze expansion and standardize pack-out first.

- Jika Anda mencetak gol 4–7, improve one lane at a time with a measured pilot.

- Jika Anda mencetak gol 8–10, use your data to simplify tiers and reduce cost.

Kasus dunia nyata: A program reduced refunds after switching from “fastest delivery” to “fastest safe lane” rules and tracking failures weekly.

How do you choose lane tiers for affordable temperature-controlled express delivery?

The cheapest option in affordable temperature-controlled express delivery is the one that survives your “doorstep reality.” Doorstep reality means the box may sit outside longer than you expect, and the recipient may not open the door immediately. When you plan for that, you stop overpaying for premium service where packaging can handle it.

A simple lane tier model keeps operations consistent. It also makes pricing easier because you are not inventing a new plan for every order.

Lane tier decision tool (cepat, operasional)

| Lane tier | Typical transit reality | Pendekatan pengemasan | Apa artinya bagimu |

|---|---|---|---|

| Pendek (lokal) | lebih sedikit sentuhan | light insulation + right coolant | lowest cost path |

| Sedang (regional) | more handling | isolasi standar + lane coolant | stable repeatability |

| Panjang (far) | higher delay probability | isolasi yang lebih kuat + strict cutoffs | fewer failures and reships |

Tip dan saran praktis

- Map ZIPs to tiers: don’t let staff guess under pressure.

- Set cutoffs by pickup + lalu lintas: late cutoffs create rushed packing.

- Don’t over-upgrade service level: upgrade only when the lane can’t be protected safely.

Kasus dunia nyata: A shipper reduced premium express usage by applying a “short lane” rule set to nearby regions while keeping outcomes stable.

What packaging makes affordable temperature-controlled express delivery possible?

Packaging is the steering wheel of affordable temperature-controlled express delivery because it defines your buffer when delays happen. The goal is not “maximum cold.” The goal is “in range long enough,” with the lowest total cost and simplest rules.

Start with a small, repeatable menu. Too many box sizes and pack-outs create mistakes that look like “random” temperature problems. A small menu makes training faster and outcomes more predictable.

Ukuran yang tepat: the fastest cost + performance win

Right-sizing reduces billed volume and often reduces coolant need. It also improves thermal performance by reducing warm air trapped inside the shipper. Think of warm air as “free heat.”

| Right-sizing factor | Too large | Right-sized | Apa artinya bagimu |

|---|---|---|---|

| Celah udara | warm air pockets | minimal void | slower warming |

| Coolant need | extra packs | paket lebih sedikit | lower weight and spend |

| Damage risk | shifting and crushing | stable load | klaim yang lebih sedikit |

Tip dan saran praktis

- Local deliveries: use smaller cartons and reduce void fill first.

- Pengiriman regional: keep a standard carton set and never “freestyle.”

- High-value items: add a closure check step (verified before release).

Kasus dunia nyata: A shipper reduced excursions by moving from many carton sizes to a few standardized options with lane-specific coolant rules.

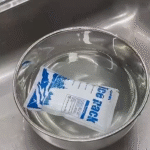

How do you reduce coolant cost in affordable temperature-controlled express delivery?

To keep affordable temperature-controlled express delivery affordable, coolant must match the lane—not your anxiety. Over-cooling adds weight and cost. Under-cooling adds refunds and reputation damage. A repeatable recipe stops both.

A practical way to standardize is to define coolant in “units” so your team stops guessing.

Lane-based coolant recipes (starter framework)

| Lane tier | Default coolant units | When to add 1 satuan | Apa artinya bagimu |

|---|---|---|---|

| Pendek | 1 | hari-hari yang panas, porch risk | keeps costs low |

| Sedang | 2 | rute multi-stop, penjemputan terlambat | adds stability |

| Panjang | 3 | peak congestion, high uncertainty | prevents expensive failures |

Tip dan saran praktis

- Post rules at the packing station: one page beats a long manual.

- Protect “touch time”: keep packs frozen until the last moment.

- Hindari kontak langsung: use a divider layer when freezing is harmful.

Kasus dunia nyata: A brand reduced coolant spend by standardizing placement and reducing air gaps, not by taking bigger risks.

How do you stop “insurance overpacking” in affordable temperature-controlled express delivery?

The best way to stop overpacking in affordable temperature-controlled express delivery is to combine a packaging buffer with an operational rescue buffer. When you have rescue options, you don’t need to pack for disasters every time. That is how you reduce weight without raising failure rate.

This is the simplest model to teach your team because it explains Mengapa you are reducing coolant. It also gives customer support a clear playbook when things go wrong.

The “Two Buffers” approach

| Buffer type | Apa yang dicakupnya | How you build it | Apa artinya bagimu |

|---|---|---|---|

| Packaging buffer | small delays, door time | isolasi + correct coolant layout | fewer normal-day excursions |

| Operational buffer | big delays, missed doors | reroute + redirect + swap options | fewer total losses and refunds |

Tip dan saran praktis

- Set a door rule: don’t leave cold shipments unattended for long.

- Use a staffed backup site: it prevents doorstep warming losses.

- Keep rescue kits ready: spare coolant and tape save money fast.

Kasus dunia nyata: A business reduced pack-out weight after adding a backup pickup point and clear missed-door rules.

What SOPs keep affordable temperature-controlled express delivery consistent?

Affordable temperature-controlled express delivery becomes affordable when it becomes boring—repeatable steps, fewer choices, lebih sedikit kesalahan. Your SOP should be short, visual, and enforced. If it cannot be followed during rush hours, it is not an SOP.

Start with a simple pack-out workflow and audit a small sample every shift. This reduces variation between staff and makes problems visible before they become refunds.

The 8-step packing SOP (sederhana, berulang)

- Confirm lane tier and service level

- Pick the correct carton size

- Add insulation panels (jika digunakan)

- Place coolant according to recipe

- Load product and reduce air gaps

- Seal using a closure checklist

- Apply labels (orientasi + “perishable”)

- Scan/record pack-out completion (time-stamped proof)

A 90-second audit that prevents expensive drift

| Audit item | Periksa cepat | Kegagalan umum | Apa artinya bagimu |

|---|---|---|---|

| Kualitas segel | fully closed | small gaps | faster warming |

| Tata letak pendingin | matches photo | random placement | pendinginan yang tidak merata |

| Waktu pementasan | minimal waiting | long idle | warms before pickup |

| Kejelasan label | temp band visible | unclear handling | more mishandling |

(Tip: keep the audit short so it actually happens.)

How do you add proof without breaking affordability?

Proof in affordable temperature-controlled express delivery works best as a ladder: light proof for low-risk lanes, stronger proof only where it changes decisions. The most expensive monitoring is monitoring you cannot act on. If you collect data but don’t change process, you paid for decoration.

Start with sampling and tighten the loop weekly. When sampling shows stability, you reduce sampling. When conditions change, you temporarily increase it.

A simple sampling plan (starter)

- jalur baru: monitor 10–20% of shipments for 2 minggu -minggu

- Stable lane: monitor 2–5% monthly

- Hot season or changes: increase sampling temporarily

Tip dan saran praktis

- Place sensors where heat enters: near the wall and near the product core.

- Lacak menit di luar jangkauan: averages hide spikes.

- Close the loop weekly: monitoring without process change is wasted spend.

Kasus dunia nyata: A shipper lowered sensor spend after proving lane stability and reducing sampling.

How do you stay compliant while keeping it affordable?

Compliance becomes affordable when your procedures are simple, used daily, and written down. Untuk pengiriman makanan, KITA. sanitary transportation guidance under FSMA emphasizes preventing practices like failure to refrigerate during transport. Regulations also point to having written procedures for temperature control when required.

You do not need a 50-page manual. You need a one-page SOP that matches reality and includes an exception plan.

The 1-page SOP template (apa yang harus disertakan)

- Product category and required temperature band

- Approved seasonal pack-out (musim panas/musim dingin)

- Maximum allowed time outside cold storage during packing

- Delivery window rules and “no safe drop” triggers

- Exception plan (menunda, kerusakan, rejection, pengiriman ulang)

2025 perkembangan dan tren terkini

Di dalam 2025, affordable temperature-controlled express delivery is moving toward tighter operational discipline and smarter reuse. Many teams are shifting from “single-use everything” toward controlled reuse programs, and they are narrowing delivery windows to reduce failed attempts. These changes improve temperature outcomes while lowering total cost.

Cuplikan kemajuan terbaru

- More tiered service menus: customers choose price vs certainty more clearly.

- Better workflow design: teams reduce dwell time using tighter handoff rules.

- Outcome measurement grows: cost per successful delivery is replacing cost per shipment.

Wawasan pasar: buyers increasingly judge performance by outcomes and evidence that does not add friction.

Pertanyaan yang sering diajukan

Q1: What makes affordable temperature-controlled express delivery possible?

Pengulangan. Tight lanes, right-sized packaging, and fewer failures reduce total cost more than rate shopping.

Q2: Should I always choose the cheapest packaging?

TIDAK. Cheap packaging that causes reships is expensive. Match packaging to lane time plus a realistic delay buffer.

Q3: How do I reduce coolant spend without raising risk?

Reduce air gaps and improve seals first, then standardize layout. Only then lower coolant safely.

Q4: Do I need real-time tracking for affordable temperature-controlled express delivery?

Tidak selalu. Start with sample loggers for lane validation and scale up only for critical, rescue-capable shipments.

Q5: What is the fastest operational fix for affordability?

Mengurangi waktu tunggu. Shorter staging and faster handoffs often improve success rate without more materials.

Q6: How do I set pricing that customers accept?

Use tiers with clear promises. Offer an economy option for low-risk orders and a premium option for critical needs.

Ringkasan dan Rekomendasi

Affordable temperature-controlled express delivery is a system, not a single trick. Ukur biaya per pengiriman yang berhasil, not just courier rates. Build lane tiers, right-size packaging, and use coolant recipes that match transit reality. Add proof through a monitoring ladder and improve one root cause each week.

Langkah selanjutnya (CTA)

Memilih satu jalur and run a 30-shipment review. Hitung biaya per pengiriman yang berhasil, identify the top failure cause, and fix that first. Then right-size packaging to lock in savings and keep results stable.

Tentang tempk

Dan Tempk, we focus on practical cold chain packaging and workflows that support affordable temperature-controlled express delivery at scale. We design lane-based pack-out logic, SOP sederhana, and proof plans that reduce waste and prevent costly failures.

Panggilan untuk bertindak: Write down your temperature band, typical and worst-day lane time, and current success rate. Then request a lane pilot plan targeting one improvement like reducing dwell time or right-sizing.