Konsultan Rantai Dingin: Apakah Anda Membutuhkan Bimbingan Ahli?

Diperbarui November 18 2025

Menjaga keamanan produk yang mudah rusak saat dibawa melalui jaringan gudang dan kendaraan kini semakin sulit. Konsultan rantai dingin adalah spesialis yang membantu Anda mendesain, mengelola dan mengoptimalkan rantai pasokan yang sensitif terhadap suhu ini. Mereka menggabungkan pengetahuan logistik dengan pengetahuan peraturan dan keahlian teknologi untuk mengurangi pembusukan, menurunkan biaya dan melindungi keselamatan pasien. Laporan pasar baru-baru ini menunjukkan bahwa pasar logistik rantai dingin global akan meningkat tiga kali lipat dari USD 436.30 miliar masuk 2025 menjadi sekitar USD 1,359.78 miliar oleh 2034. Dengan pertumbuhan pesat ini muncul tantangan baru dalam hal kepatuhan, adopsi teknologi dan keberlanjutan. Artikel ini menjelaskan bagaimana konsultan dapat membantu Anda mengatasi kompleksitas.

Apa yang dilakukan konsultan rantai dingin?, dan apa perbedaannya dengan pakar rantai pasokan pada umumnya?

Mengapa Anda harus mempertimbangkan untuk menyewa konsultan untuk operasi sensitif suhu Anda?

Teknologi dan alat apa yang mendukung konsultasi rantai dingin modern?

Bagaimana Anda bertemu 2025 persyaratan peraturan seperti FSMA 204 dan pedoman internasional?

Tren apa yang membentuk industri rantai dingin 2025 dan seterusnya?

Apa Itu Konsultan Cold Chain dan Bagaimana Cara Kerjanya?

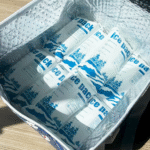

Konsultan rantai dingin adalah pakar rantai pasokan khusus yang merancang dan mengawasi sistem distribusi yang dikontrol suhu. Mereka biasanya berasal dari latar belakang teknik atau farmasi dan fokus pada pemeliharaan produk seperti vaksin, biologis dan makanan yang mudah rusak dalam kisaran suhu yang ketat. Karena rantai dingin farmasi sangat diatur dan rumit secara teknis, produsen sering kali melakukan outsourcing validasi distribusi kepada konsultan pihak ketiga. Para ahli ini memberikan rekomendasi mengenai pengemasan termal, jalur transportasi dan tanggapan peraturan serta memberikan perspektif yang tidak memihak mengenai rantai dingin biofarmasi.

Merancang Proses Sensitif Suhu

Inti dari pekerjaan konsultan adalah desain proses. Mereka menganalisis alur kerja yang ada, mengidentifikasi perubahan suhu dan menciptakan solusi yang menjaga integritas produk selama penyimpanan, transportasi dan pengiriman last mile. Konsultan mungkin merekomendasikan:

| Area Proses | Aktivitas Utama | Kontribusi Konsultan | Manfaat untuk Operasi Anda |

| Kemasan | Pemilihan kemasan termal aktif dan pasif | Evaluasi isolasi, bahan perubahan fase, dan ketahanan kemasan | Mengurangi risiko perubahan suhu dan menurunkan biaya pengemasan |

| Kualifikasi Transportasi | Analisis rute, pemilihan operator, kualifikasi jalur | Menilai peralatan operator, kemampuan pelacakan dan riwayat kepatuhan | Peningkatan pengiriman tepat waktu dan mengurangi pembusukan |

| Validasi & Pengujian | Simulasikan peristiwa termal kasus terburuk | Melakukan simulasi transportasi dan profil termal menggunakan laboratorium teknik | Keyakinan bahwa produk tetap sesuai spesifikasi bahkan dalam kondisi ekstrim |

| Pengajuan Peraturan | Siapkan tanggapan untuk FDA, EMA atau SIAPA | Menyelaraskan dokumentasi dengan Praktik Distribusi yang Baik dan FSMA global 204 persyaratan | Persetujuan lebih cepat dan lebih sedikit masalah kepatuhan |

Membangun Keahlian Melampaui Nasihat

Konsultan cold chain terbaik tidak hanya memberikan saran — mereka juga memberikan saran menerapkan solusi. Banyak perusahaan mempekerjakan insinyur konsultan yang memadukan pemodelan matematika dan pengujian langsung. Para profesional ini memberikan rekomendasi pengemasan yang hemat biaya, penilaian risiko formal dan simulasi transportasi yang dirancang untuk menguji skenario terburuk. Mereka tetap bersama Anda melalui analisis, pengujian dan implementasi, memastikan bahwa rekomendasi teoretis dapat diterapkan dalam operasi dunia nyata. Pendekatan ini mengurangi risiko trial and error yang mahal dan mempercepat persetujuan peraturan.

Mengapa Bisnis Mempekerjakan Konsultan Cold Chain?

Menyewa konsultan rantai dingin menghasilkan manfaat yang terukur, terutama ketika rantai pasok menjadi rumit atau ketika peraturan yang dipertaruhkan sangat tinggi. Alasan utamanya mencakup peningkatan efisiensi, pengurangan biaya dan mitigasi risiko.

Peningkatan Efisiensi dan Penghematan Biaya

Konsultan dapat menyederhanakan operasi dan mengidentifikasi area dimana sumber daya terbuang sia-sia. Survei rantai pasokan yang dikutip oleh Visigistics menemukan hal itu 79 % banyak perusahaan dengan rantai pasokan berkinerja tinggi mencapai pertumbuhan pendapatan jauh di atas rata-rata industrinya. Dengan menganalisis proses, konsultan membantu perusahaan mengoptimalkan sumber daya, mengurangi biaya persediaan dan mempercepat waktu pengiriman. Peningkatan ini menghasilkan penghematan biaya langsung dan penggunaan modal yang lebih baik.

Peningkatan Visibilitas dan Pengambilan Keputusan

Kurangnya visibilitas adalah masalah umum dalam logistik rantai dingin. Konsultan memperkenalkan alat dan proses digital yang memberikan wawasan operasional secara real-time. Mereka membantu bisnis mengidentifikasi hambatan, mengurangi risiko dan meningkatkan pengambilan keputusan. Transparansi yang ditingkatkan juga mendorong kolaborasi antar pemasok, operator dan pusat distribusi, menghasilkan operasi yang lebih lancar dan kepuasan pelanggan yang lebih tinggi.

Perencanaan Strategis, Manajemen Risiko dan Skalabilitas

Konsultan membantu perencanaan strategis dengan memberikan perspektif segar dan tolok ukur terhadap praktik terbaik industri. Mereka membantu perusahaan menyelaraskan pengadaan, proses produksi dan pengiriman serta mengembangkan strategi untuk meningkatkan skala operasi sambil mengelola risiko. Dengan mengidentifikasi potensi gangguan sejak dini dan merekomendasikan rencana darurat, konsultan membangun ketahanan dalam rantai pasokan Anda. Tim multi ahli memberikan pengetahuan lintas industri, menawarkan solusi yang disesuaikan untuk tantangan unik.

Kapan Anda Harus Menyewa Konsultan?

Anda mungkin mempertimbangkan untuk menyewa konsultan rantai dingin ketika:

Anda meluncurkan produk baru yang sensitif terhadap suhu dan perlu merancang atau menskalakan rantai dingin ujung ke ujung.

Perusahaan Anda telah mengalami perubahan suhu berulang kali, kerusakan atau penarikan produk.

Persyaratan peraturan telah berubah dan Anda memerlukan bantuan untuk memperbarui proses agar mematuhi FSMA 204 atau pedoman internasional.

Anda berencana untuk berekspansi ke wilayah baru dan membutuhkan keahlian logistik lokal.

Anda ingin membandingkan operasi Anda dengan standar industri atau bersiap menghadapi audit dan inspeksi.

Teknologi dan Alat yang Digunakan oleh Konsultan Cold Chain

Konsultasi rantai dingin modern adalah tentang teknologi dan juga keahlian logistik. Kebangkitan Internet of Things (IoT), platform cloud dan kecerdasan buatan (Ai) telah merevolusi cara produk yang sensitif terhadap suhu dipantau dan dikendalikan.

Solusi Pemantauan Rantai Dingin

Solusi pemantauan rantai dingin menggunakan sensor, pencatat data dan platform cloud untuk melacak suhu dan kelembapan di seluruh rantai pasokan. Solusi ini mencegah pembusukan dan memastikan kepatuhan terhadap FDA, Pedoman WHO dan UE. Menurut Solusi Identec, sistem pemantauan canggih mengintegrasikan AI dan analisis prediktif untuk mendeteksi potensi kegagalan sebelum terjadi, mengoptimalkan efisiensi rantai pasokan. Pasar pemantauan rantai dingin global diproyeksikan tumbuh dari USD 7.6 miliar masuk 2025 ke USD 28.3 miliar oleh 2035 dengan CAGR sebesar 14.0 %, didorong oleh permintaan akan logistik yang sensitif terhadap suhu dan pemantauan yang mendukung IoT.

Teknologi Pemantauan Utama

| Teknologi | Keterangan | Manfaat | Pertimbangan |

| Data Loggers | Perangkat bertenaga baterai ditempatkan di dalam unit penyimpanan dingin yang mencatat suhu dan kelembapan dari waktu ke waktu | Terjangkau, dapat diandalkan dan mudah diterapkan; menyediakan data historis untuk audit | Pengambilan data secara manual dapat menunda respons terhadap kunjungan |

| Sensor Nirkabel Berbasis IoT | Sensor yang mengirimkan data waktu nyata ke platform cloud melalui Wi Fi, seluler atau LoRaWAN | Pemantauan waktu nyata, peringatan otomatis dan pemeliharaan prediktif mengurangi pembusukan | Memerlukan konektivitas jaringan dan dapat menimbulkan risiko keamanan siber |

| Sensor Suhu RFID | Tag tertanam dengan sensor suhu, dipindai secara otomatis di pos pemeriksaan | Mengotomatiskan pengumpulan data dan mengurangi kesalahan manusia; cocok untuk gudang berskala besar | Batasan jangkauan sinyal dan gangguan dari logam atau cairan |

| Pelacak Berbasis GPS | Perangkat yang menggabungkan pelacakan lokasi dengan pemantauan suhu | Memberikan visibilitas waktu nyata ke lokasi dan kondisi pengiriman; meningkatkan keamanan | Biaya lebih tinggi dan ketergantungan pada jangkauan satelit atau seluler |

Ai, Analisis Prediktif dan Robotika

AI meningkatkan operasi rantai dingin dengan menganalisis kumpulan data yang besar, memprediksi kegagalan peralatan dan mengoptimalkan rute. Precedence Research mencatat bahwa AI dalam logistik rantai dingin mengotomatiskan tugas, meningkatkan optimalisasi rute, menyediakan pemantauan waktu nyata dan mengurangi pembusukan. Algoritme prediktif memperkirakan fluktuasi permintaan, mengantisipasi penundaan dan menyesuaikan pengaturan pendinginan untuk menghemat energi. Robotika gudang mempercepat pengambilan dan pengepakan sekaligus menjaga integritas suhu. Saat terintegrasi dengan digital twins dan analisis cloud, alat-alat ini memungkinkan konsultan untuk memodelkan skenario “bagaimana jika” dan merancang sistem yang tangguh.

Platform dan Integrasi Digital

Konsultan juga menerapkan platform digital yang menggabungkan data dari berbagai sumber — sensor, perencanaan sumber daya perusahaan (ERP) sistem dan database peraturan. Platform ini menyediakan dasbor dengan indikator kinerja utama (KPI), seperti deviasi suhu rata-rata, persentase pengiriman sesuai kepatuhan dan jejak karbon. Melalui integrasi, manajer mendapatkan pandangan holistik tentang rantai dingin dan dapat mengambil keputusan dengan cepat.

Persyaratan Kepatuhan dan Peraturan untuk 2025

Operasi rantai dingin tunduk pada berbagai peraturan yang bertujuan melindungi kesehatan masyarakat. Memahami dan mematuhi peraturan ini sangat penting bagi bisnis apa pun yang menangani barang-barang yang sensitif terhadap suhu.

FSMA 204 dan Ketertelusuran Pangan

Di Amerika Serikat, Undang-Undang Modernisasi Keamanan Pangan (FSMA) Bagian 204 memperkenalkan persyaratan ketertelusuran yang ketat untuk pangan berisiko tinggi. Mulai bulan Januari 6 2025, FSMA 204 berlaku untuk semua makanan dalam Daftar Ketertelusuran Makanan FDA. Entitas yang terlibat dalam manufaktur, pengolahan, pengepakan atau penyimpanan makanan ini harus menyimpan catatan yang berisi elemen data penting (KDE) untuk peristiwa pelacakan penting (CTE). Mereka harus dapat memberikan informasi ini kepada FDA di dalamnya 24 jam. Kepatuhan bersifat wajib pada bulan Januari 20 2026, meskipun pemeriksaan rutin mungkin baru dimulai 2027.

Konsultan rantai dingin membantu perusahaan memetakan proses mereka, mengidentifikasi CTE dan menerapkan solusi ketertelusuran digital yang menangkap KDE secara otomatis. Mereka juga menyarankan pelabelan, berbagi data dan penyimpanan dokumen untuk memastikan respons cepat selama penarikan atau inspeksi.

Pedoman Internasional dan Praktik Distribusi yang Baik

Di luar Amerika Serikat, perusahaan harus mematuhi standar internasional seperti Organisasi Kesehatan Dunia (SIAPA) Praktik Distribusi yang Baik (PDB) dan Uni Eropa (UE) PDB. Pedoman ini menetapkan standar minimum untuk penyimpanan, transportasi dan dokumentasi produk obat. Konsultan memastikan pemetaan suhu, kualifikasi dan pemantauan berkelanjutan memenuhi standar global terbaru. Mereka juga mempersiapkan perusahaan untuk diaudit oleh lembaga seperti European Medicines Agency dan Health Canada.

Keberlanjutan dan Keamanan Pangan

Peraturan semakin menekankan keberlanjutan dan pengurangan limbah. Kesepakatan Hijau Eropa, Misalnya, mendorong penurunan emisi dalam transportasi dan mendorong kemasan yang dapat digunakan kembali. Banyak pemerintah menawarkan insentif untuk menerapkan sistem pendingin hemat energi dan solusi energi terbarukan. Konsultan dapat membantu bisnis menyelaraskan dengan inisiatif ini sambil menjaga keamanan produk.

Memilih Konsultan Cold Chain yang Tepat: Daftar Periksa

Memilih konsultan yang tepat adalah keputusan strategis. Di bawah ini adalah daftar periksa untuk memandu pilihan Anda:

Keahlian industri: Carilah konsultan dengan pengalaman di sektor Anda (Farmasi, makanan & minuman, Bioteknologi, dll.) dan bukti keberhasilan proyek.

Kredensial teknis: Pastikan tim tersebut terdiri dari insinyur atau profesional bersertifikat yang memahami dinamika termal, ilmu pengemasan dan persyaratan peraturan.

Pengetahuan peraturan: Tanyakan tentang pengalaman dengan FSMA, PDB WHO, PDB UE dan peraturan terkait lainnya. Konsultan harus siap untuk mendukung audit dan pengarsipan.

Kemampuan teknologi: Menilai pemahaman konsultan terhadap sensor IoT, Ai, platform digital dan analisis data. Mereka harus mengusulkan solusi yang terintegrasi dengan sistem Anda.

Dukungan implementasi: Pilih perusahaan yang akan bertahan melalui pengujian dan peluncuran, tidak sekedar menyampaikan laporan. Dukungan langsung selama validasi dan pemantauan memastikan rekomendasi diterapkan dalam praktik.

Referensi dan studi kasus: Mintalah referensi dari proyek serupa untuk mengukur rekam jejak konsultan.

Skalabilitas dan inovasi: Pertimbangkan apakah konsultan dapat beradaptasi dengan pertumbuhan Anda dan menerapkan teknologi baru. Dengan pasar rantai dingin diperkirakan mencapai USD 1,611 miliar oleh 2033, mitra yang berwawasan ke depan sangatlah penting.

Alat Penilaian Diri

Untuk memutuskan apakah Anda memerlukan konsultan rantai dingin, nilailah diri Anda sendiri pada pertanyaan-pertanyaan berikut (1 = Sangat tidak setuju, 5 = Sangat setuju). Jika rata-rata Anda di bawah 3, keahlian eksternal dapat menambah nilai yang signifikan.

Kami menjaga visibilitas penuh suhu dan lokasi untuk semua pengiriman.

Tingkat pembusukan dan penyimpangan kami secara konsisten berada di bawah standar industri.

Kami memiliki staf yang berdedikasi dengan pengetahuan peraturan yang mendalam (FSMA, PDB, dll.).

Teknologi rantai dingin kami (sensor, platform pemantauan) terkini.

Kami secara rutin mengaudit proses kami dan melakukan penilaian risiko.

Kami siap untuk peraturan yang akan datang seperti FSMA 204 dan dapat memberikan data di dalamnya 24 jam.

Kami memiliki rencana darurat untuk kegagalan peralatan, penundaan dan pemadaman listrik.

2025 Tren dalam Konsultasi dan Logistik Rantai Dingin

Ekspansi Pasar yang Pesat dan Pertumbuhan Regional

Industri rantai dingin mengalami ekspansi yang pesat. Precedence Research melaporkan bahwa ukuran pasar logistik rantai dingin global adalah USD 436.30 miliar masuk 2025 dan akan mencapai sekitar USD 1,359.78 miliar oleh 2034, tumbuh di CAGR OF 13.46 %. Asia Pasifik diperkirakan memiliki tingkat pertumbuhan tertinggi 14.3 %, sementara transportasi berpendingin diperkirakan akan meningkat pada 13 % CAGR.

Grand View Research memproyeksikan pasar rantai dingin yang lebih luas (termasuk penyimpanan dan transportasi) tumbuh dari USD 316.34 miliar masuk 2024 ke USD 1,611.02 miliar oleh 2033, CAGR sebesar 20.1 %. Amerika Utara menyumbang 34.4 % pendapatan di 2024, namun India diharapkan menjadi negara dengan pertumbuhan tercepat. Konsultan harus memahami perbedaan infrastruktur regional, peraturan dan permintaan konsumen saat merancang jaringan rantai dingin.

Digitalisasi dan Analisis Prediktif

Adopsi perangkat IoT, AI dan analisis prediktif semakin cepat. Identec Solutions menyoroti bahwa sistem pemantauan canggih mengintegrasikan AI untuk mencegah kegagalan sebelum terjadi. Analis pasar mencatat bahwa penerapan solusi pemantauan secara global didorong oleh peraturan yang ketat, kemajuan teknologi dan globalisasi. Karena semakin banyak perusahaan yang melakukan digitalisasi, konsultan yang menguasai analisis data, pembelajaran mesin dan kembaran digital akan sangat diminati.

Kepatuhan dan Ketertelusuran sebagai Imperatif Strategis

Dengan FSMA 204 mulai berlaku dan peraturan serupa di seluruh dunia, ketertelusuran bukan lagi sebuah pilihan. Konsultan membantu menerapkan sistem yang menangkap elemen data utama untuk pelacakan peristiwa penting dan menyimpan catatan untuk pelaporan cepat. Bisnis yang berinvestasi sejak dini akan mengurangi risiko, menghindari penalti dan membangun kepercayaan pelanggan.

Keberlanjutan dan Efisiensi Energi

Kepedulian terhadap lingkungan mendorong inovasi. Sistem pendingin hemat energi, integrasi energi terbarukan dan pengemasan berkelanjutan mengurangi jejak karbon dan biaya pengoperasian. Pemerintah dan konsumen berupaya menurunkan emisi dan limbah. Konsultan perlu memasukkan metrik keberlanjutan ke dalam desain mereka dan memberikan saran mengenai insentif dan peluang pendanaan.

Konsolidasi Pasar dan Pelayanan Terpadu

Lanskap rantai dingin sedang berkonsolidasi. Penyedia logistik besar mengakuisisi perusahaan spesialis untuk menawarkan layanan end to end. Pada saat yang sama, pendatang baru, termasuk startup teknologi, memperkenalkan sensor pintar, platform blockchain dan analitik berbasis AI. Konsultan harus menavigasi ekosistem yang terus berkembang ini, mengidentifikasi mitra yang dapat diandalkan dan mengintegrasikan solusi terbaik untuk klien.

Pertanyaan yang sering diajukan

Q 1: Apa tanggung jawab utama konsultan rantai dingin??

Konsultan menganalisis proses sensitif terhadap suhu yang ada, merekomendasikan solusi pengemasan dan transportasi, memastikan kepatuhan terhadap peraturan, merancang sistem pemantauan dan membantu implementasi. Tujuan mereka adalah menjaga integritas produk, mengurangi biaya dan mengoptimalkan operasi.

Q 2: Bagaimana konsultan membantu kepatuhan terhadap peraturan?

Mereka mengidentifikasi peristiwa pelacakan penting, menerapkan sistem yang menangkap elemen data utama dan menyiapkan dokumentasi untuk badan pengatur. Konsultan membantu bisnis memenuhi FSMA 204 persyaratan ketertelusuran oleh 2026 dan selaras dengan Praktik Distribusi yang Baik dari WHO dan Uni Eropa.

Q 3: Apakah konsultan rantai dingin hanya untuk perusahaan farmasi besar?

TIDAK. Organisasi mana pun yang menangani produk sensitif terhadap suhu — termasuk produsen makanan, pengecer, platform grosir e-commerce dan produsen bahan kimia – dapat memperoleh manfaat dari keahlian konsultan. Seiring dengan pertumbuhan pasar rantai dingin dan peraturan yang semakin ketat, perusahaan kecil dan menengah semakin mencari bimbingan eksternal.

Q 4: Bagaimana konsultan membenarkan biayanya?

Dengan mengurangi pembusukan, meningkatkan efisiensi dan menghindari sanksi regulasi, konsultan memberikan laba atas investasi yang kuat. Studi kasus menunjukkan bahwa organisasi dengan rantai pasokan berkinerja tinggi menikmati pertumbuhan pendapatan jauh di atas rata-rata industri.

Ringkasan dan Rekomendasi

Itu rantai dingin berkembang pesat, didorong oleh pertumbuhan di bidang farmasi, Bioteknologi, makanan dan perdagangan elektronik global. Dengan pasar yang diproyeksikan melampaui USD 1.6 triliun sebesar 2033 dan meningkatkan pengawasan peraturan, dunia usaha tidak dapat menganggap logistik yang sensitif terhadap suhu hanya sebagai sebuah renungan. Konsultan rantai dingin memberikan pengetahuan khusus yang mencakup teknik, regulasi dan teknologi. Mereka membantu merancang proses yang berketahanan, mengadopsi alat pemantauan canggih dan memastikan kepatuhan terhadap aturan kompleks seperti FSMA 204.

Untuk memanfaatkan manfaat ini:

Nilai kemampuan Anda saat ini menggunakan alat penilaian mandiri dan mengidentifikasi kesenjangan dalam visibilitas, teknologi dan kepatuhan.

Libatkan konsultan sejak dini ketika merencanakan produk baru, memasuki pasar baru atau merespons perubahan peraturan.

Prioritaskan digitalisasi dan analisis prediktif untuk mengurangi pembusukan dan meningkatkan kelincahan operasional.

Tanamkan keberlanjutan ke dalam desain rantai dingin Anda dengan memilih peralatan hemat energi dan kemasan yang dapat digunakan kembali.

Berkolaborasi dengan mitra di seluruh rantai pasokan untuk berbagi data dan menyelaraskan upaya kepatuhan.

Tentang tempk

Tempk adalah penyedia spesialis solusi rantai dingin, memberikan keahlian teknik, teknologi pemantauan canggih dan dukungan peraturan untuk bisnis di bidang farmasi, pangan dan bioteknologi. Kami menggabungkan bahan kimia, disiplin ilmu teknik mesin dan biomedis untuk merancang sistem pengontrol suhu yang komprehensif. Tim kami telah membantu organisasi mencapai persetujuan lebih cepat, mengurangi pembusukan dan mengintegrasikan solusi energi terbarukan. Dengan pengalaman lebih dari satu dekade, Kami tetap terdepan dalam perubahan peraturan dan inovasi teknologi untuk membantu Anda membangun rantai dingin yang berketahanan dan berkelanjutan.

Panggilan untuk bertindak

Siap mengoptimalkan rantai pasokan Anda yang sensitif terhadap suhu? Hubungi tim kami untuk konsultasi dan temukan bagaimana pendekatan berbasis teknis kami dapat melindungi produk Anda, mengurangi biaya dan memastikan kepatuhan. Kami di sini untuk membantu Anda membangun ketahanan, rantai dingin yang efisien dan berkelanjutan.