Dalam tarian rumit rantai pasokan global, mempertahankan kontrol suhu yang tepat untuk barang-barang sensitif—mulai dari vaksin yang menyelamatkan jiwa hingga makanan lezat—bukan lagi suatu pilihan. Custom insulated bags have emerged as indispensable allies, combining portability with cutting-edge thermal engineering to bridge the gap between bulk storage and last-mile delivery

Why Custom Insulated Bags Matter More Than Ever

Temperature excursions during transit cost businesses $35 billion annually in spoiled goods

. Traditional solutions like refrigerated trucks excel in bulk transport but fail in dynamic scenarios:

- Urban Deliveries: 68% of food delivery riders report temperature fluctuations during short trips

- Pharma Emergencies: Insulin and mRNA vaccines require strict 2–8°C environments; even a 2°C deviation can render them useless

- Sustainability Demands: Single-use packaging accounts for 23% of cold chain carbon emissions

Custom insulated bags address these challenges by offering tailored solutions—whether it’s a lunchbox for office commuters or a medical-grade carrier for transcontinental vaccine shipments.

Inovasi Tempk: Where Science Meets Practicality

Tempk, a pioneer in intelligent cold chain solutions, has redefined custom insulated bags with these breakthroughs:

1. Isolasi Adaptif Multi-Lapisan

TempkLapisan Hibrida Aeroflex™ integrates three critical components

- Panel Aerogel: Reflect 97% panas radiasi, bahkan dalam kondisi sekitar 40°C.

- Materi Perubahan Fase (PCMS): Automatically absorb/release heat at preset thresholds (MISALNYA., -18°C for seafood).

- Recycled PET Core: Terbuat dari 85% post-consumer plastics, mengurangi jejak karbon dengan 30% vs.. busa tradisional.

2. Smart Logistics Integration

Embedded IoT sensors track real-time metrics

- Suhu (± akurasi 0,5 ° C.)

- Humidity and GPS location

Sinkronisasi data melalui Bluetooth ke TempkAplikasi ColdChain Guardian™, enabling proactive adjustments and automated compliance reports for FDA/EU GDP standards.

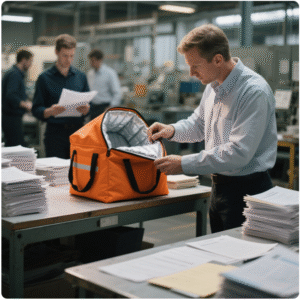

3. Ergonomis & Customizable Design

- Modular Compartments: Fit everything from 100 vaccine vials to 20kg of fresh produce

- Anti-Microbial Liners: FDA-approved PVC-free interiors resist bacterial growth

- Branding Flexibility: Laser-printed logos withstand 200+ washes, maintaining corporate identity

Real-World Impact Across Industries

Farmasi: Selama a 2024 African vaccine rollout, Tempk bags maintained 2–8°C for 96 hours in 42°C heat—exceeding WHO standards

Makanan & Minuman: A Tokyo sushi chain reduced spoilage by 40% using Tempk’s -18°C-rated bags for trans-Pacific tuna shipments

E-commerce: Tempk’s foldable designs save 70% ruang penyimpanan, ideal for seasonal delivery fleets

Masa depan: Keberlanjutan Bertemu Kecerdasan

Tempk sedang merintis:

- PCM Isi Ulang Tenaga Surya: Pilot projects in off-grid regions eliminate ice dependency

- Blockchain Traceability: Each bag’s environmental impact (CO2 dihemat, jumlah daur ulang) is immutably recorded

Custom insulated bags aren’t just containers—they’re climate-controlled lifelines. Dengan solusi Tempk, businesses don’t just ship products; they deliver trust.