Di era di mana layanan pengiriman makanan booming - diproyeksikan untuk mencapai $1.2 triliun secara global pada tahun 2030 - makanan yang memastikan tiba segar, aman, dan menarik secara visual tidak lagi opsional. Tas pengiriman makanan cetak khusus telah menjadi alat penting untuk restoran, dapur awan, dan penyedia bahan makanan, Menggabungkan kontrol suhu dengan bercerita merek. Tas -tas ini tidak hanya menjaga kualitas tetapi juga bertindak sebagai iklan seluler, Membangun kepercayaan dan loyalitas pelanggan.

Dilema pengiriman makanan: Kesegaran vs.. Tapak

Rantai dingin makanan menghadapi tekanan ganda: mempertahankan rentang suhu yang ketat (0° C - 5 ° C untuk barang yang mudah rusak) dan mengurangi limbah lingkungan. Lebih 30% makanan yang dikirim dibuang karena fluktuasi suhu atau kegagalan pengemasan, Sementara plastik sekali pakai mendominasi industri. Solusi Tradisional Seringkali mengorbankan keberlanjutan untuk fungsionalitas, Meninggalkan merek yang berjuang untuk menyeimbangkan efisiensi operasional dengan nilai-nilai sadar lingkungan.

Tas terisolasi cetak khusus menangani masalah ini secara langsung:

-

Memperluas kesegaran: Bahan berkinerja tinggi menjaga makanan pada suhu optimal hingga 36 jam.

-

Memotong limbah: Desain yang dapat digunakan kembali menggantikan kemasan sekali pakai, menyelaraskan dengan kebijakan plastik-larangan di 70+ negara.

-

Memperkuat identitas merek: Cetakan khusus mengubah tas pengiriman menjadi aset pemasaran, Meningkatkan visibilitas dan profesionalisme.

Kantong termal Tempk: Dimana teknologi memenuhi branding

Tempk, pelopor dalam solusi rantai dingin pintar, meningkatkan pengiriman makanan dengan itu Seri FreshGuard, Dirancang untuk memenuhi tuntutan unik industri makanan:

1. Efisiensi termal yang tak tertandingi

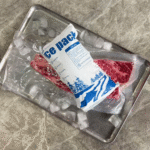

Fitur Tas Tempk Insulasi aergel tingkat NASA Dan Paket gel PCM yang aman makanan, mempertahankan suhu yang tepat antara -10 ° C dan 40 ° C. Tes independen menunjukkan a 50% laju perpindahan panas yang lebih lambat dibandingkan dengan busa EPS standar, memastikan es krim tetap beku dan salad renyah.

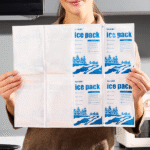

2. Opsi Kustomisasi Hibrida

Merek dapat memilih dari:

-

Pencetakan resolusi tinggi: Logo dan karya seni tahan pudar yang bertahan dari kondisi lembab.

-

Kompartemen modular: Pembagi yang dapat disesuaikan untuk pesanan multi-dish (MISALNYA., kari panas di samping makanan penutup dingin).

-

Integrasi Kode QR: Label yang dapat dipindai untuk penelusuran, promosi, atau info alergi.

3. Keberlanjutan dibangun

Terbuat dari Liner hewan peliharaan daur ulang yang disetujui FDA dan pelapis tahan air nabati, Tas Tempk adalah 100% dapat didaur ulang. Desain mereka yang dapat dilipat mengurangi ruang penyimpanan 60%, Menurunkan emisi transportasi untuk mitra logistik.

4. Fitur Kepatuhan Cerdas

-

Segel anti-kerusakan: Indikator pengubah warna staf peringatan jika tas dibuka di tengah transit.

-

IoT suhu penebang: Sinkronisasi dengan aplikasi pengiriman untuk berbagi data real-time dengan pelanggan (MISALNYA., “Sushi Anda tetap pada suhu 2 ° C!”).

Masa depan: Kemasan yang dipersonalisasi mendorong pertumbuhan

Karena konsumen memprioritaskan keberlanjutan dan branding pengalaman, Kantong termal cetak khusus menjadi investasi strategis. A 2023 Studi Nielsen menemukan itu 78% pengunjung lebih cenderung untuk memesan kembali dari restoran menggunakan ramah lingkungan, kemasan bermerek. Solusi Tempk memberdayakan bisnis:

-

Mengurangi jejak karbon hingga hingga 35% setiap tahun.

-

Boost Keterlibatan Media Sosial Melalui Desain Layak Instagram.

-

Mematuhi peraturan keamanan pangan FDA dan EU dengan mudah.

Kesimpulan

Tas Pengiriman Makanan Cetak Kustom Mengubah Rantai Dingin Dari Operasi Di Balik Layar Menjadi Pembeda Merek Yang Menghadapi Pelanggan. Seri FreshGuard Tempk mencontohkan pergeseran ini, menawarkan perpaduan daya tahan, intelijen, dan fleksibilitas estetika. Untuk bisnis yang bertujuan untuk menonjol di pasar yang ramai, Berinvestasi dalam inovasi seperti itu bukan hanya logistik pintar-itu adalah resep untuk kesuksesan jangka panjang.