Paket Es Kering dari Peternakan ke Meja: Bagaimana Anda Mengirimkan Segar?

Anda ingin setiap kotak tiba dalam keadaan dingin dan bersih. A paket es kering dari pertanian ke meja memberi Anda ketahanan di bawah nol untuk rute yang panjang atau panas, menjaga rasa dan keamanan tetap utuh. Pendinginan diperkirakan mencapai −78,5°C, 24–Waktu tunggu 48 jam, dan tidak ada air lelehan yang berantakan saat Anda mengemas dan melampiaskannya dengan benar. Panduan ini menunjukkan caranya, berapa banyak, dan alasannya dalam langkah-langkah praktis. Panduan gabungan ini menggabungkan dan menyempurnakan tiga rancangan sebelumnya yang harus dipenuhi 2025 praktik terbaik.

Catatan: Artikel ini menyatukan dan meningkatkan tiga draf internal menjadi satu, Pedoman yang dioptimalkan untuk SEO untuk cold chain dari pertanian ke meja.

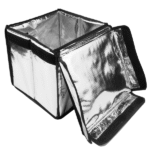

paket es kering dari pertanian ke meja

-

Bagaimana a paket es kering dari pertanian ke meja melindungi rasa dan keamanan di rute nyata

-

Berapa banyak es kering yang Anda butuhkan dengan sederhana kalkulator es kering dari pertanian ke meja

-

Yang metode pengepakan es kering mencegah kejutan beku di kotak campuran

-

Ketika paket gel atau PCM mengalahkan a paket es kering dari pertanian ke meja

-

Bagaimana memberi label UN1845 dan tetap siap diaudit

-

Apa 2025 tren penting bagi Anda rantai dingin mil terakhir

Apa yang dimaksud dengan paket es kering dari peternakan ke meja dan kapan Anda harus menggunakannya?

Paket es kering dari peternakan ke meja berisi CO₂ padat dalam kantong aman yang dapat menahan suhu di bawah nol sehingga makanan yang mudah rusak tiba dalam keadaan padat, beraroma, dan dalam spesifikasi. Gunakan untuk protein, es krim, dan item berisiko tinggi, atau rute mana pun 24 jam. Tidak berantakan karena dapat menyublim menjadi gas, bukan air, mengurangi masalah unboxing dan risiko jamur.

Dari sudut pandang praktis, Anda mendapatkan ruang kepala melawan lalu lintas dan ambang pintu yang hangat. Es kering dimulai pada suhu −109,3°F dan menenggelamkan udara dingin ke bawah. Hal ini membuatnya ideal untuk kotak CSA campuran yang proteinnya harus tetap lebih dingin dibandingkan sayuran hijau. Untuk akhir pekan dengan rute tunggal, A paket es kering dari pertanian ke meja memberi Anda kualitas yang konsisten dengan pengembalian dan tiket dukungan yang lebih sedikit.

Kalkulator es kering dari pertanian ke meja (aturan praktis)

Tip terperinci: Mulailah dengan waktu rute, volume kotak, dan isolasi. Lalu ukur paket es kering dari pertanian ke meja menggunakan estimator konservatif ini:

Es kering (kg) = [0.06 × Volume kotak (L)] × Faktor isolasi × Faktor waktu.

| Preset Penaksir | Faktor isolasi | Faktor waktu | Apa artinya bagimu |

|---|---|---|---|

| Liner tebal / EPS | 0.7 | 1.0 (24 H) | Dibutuhkan lebih sedikit massa; kontrol suhu yang lebih ketat |

| Kapal standar | 1.0 | 1.6 (36–48 h) | Tambahkan massa untuk rute panjang |

| Kotak tipis/pakai ulang | 1.3 | 2.2 (72 jam panas) | Gunakan lebih banyak massa atau tingkatkan liner |

Skenario ukuran praktis

-

Hari CSA lokal (18 L, standar, 24 H): ~1,1kg paket es kering dari pertanian ke meja.

-

Akhir pekan yang panas (18 L, standar, 36–48H): ~1,8kg paket es kering dari pertanian ke meja.

-

Regional 2 hari (28 L, lapisan tebal, 48 H): ~1,9kg paket es kering dari pertanian ke meja.

Kasus aktual: CSA campuran menambahkan 1,5kg paket es kering dari pertanian ke meja di atas penyekat karton. Protein tiba dingin; sayuran tetap segar; klaim pengembalian hangat berkurang setengahnya di bulan Juli.

Coba estimator mini (Copy -Paste Ready)

Bagaimana Anda mengemas paket es kering dari peternakan ke meja untuk kotak campuran?

Bangun “langit-langit” yang dingin,” produksi penyangga, dan buka tutupnya. Tempatkan protein di bagian bawah, tambahkan penyekat karton tipis, panggung sayuran halus di atas, lalu tempatkan paket es kering dari pertanian ke meja di atasnya dibungkus kertas kraft. Isi rongga untuk menghentikan aliran udara dan mencegah memar. Tinggalkan jalur ventilasi kecil—jangan pernah kedap gas.

Paket yang nyaman menghentikan konveksi. Udara dingin tenggelam, jadi dipasang di atas paket es kering dari pertanian ke meja air terjun dingin melalui beban. Isi rongga kertas mengalahkan bantalan udara yang roboh karena dingin. Liner dan produk didinginkan terlebih dahulu untuk mengurangi massa yang dibutuhkan sebesar 10–20% pada rute yang sama.

Persyaratan label es kering UN1845 (daftar periksa bahasa Inggris biasa)

Anda memerlukan tiga hal: sarung tangan, ventilasi, dan label yang tepat. Tandai “Es Kering (UN1845)” ditambah kilogram bersih. Jangan menutup rapat gas. Van berventilasi dan ruang pengemasan menghindari penumpukan CO₂. Latih staf untuk mengenali gejala seperti pusing dan membuka pintu untuk aliran udara sebelum menurunkan muatan. Ikuti aturan operator saat ini, Batasan es kering DOT dan IATA, dan panduan suhu USDA FSIS.

| Langkah Kemas | Apa yang harus dilakukan | Mengapa itu penting | Untuk rute Anda |

|---|---|---|---|

| Pra -chill | Liner dan protein keren | Mengurangi kebutuhan massal sebesar ~10–20% | Jalur paket lebih cepat |

| Membingungkan | Karton di atas protein | Menghentikan kejutan beku pada sayuran | Unboxing Cleaner |

| Lubang angin | Tutup retak atau lubang ventilasi | Co₂ harus melarikan diri | Keamanan + kepatuhan |

Tips yang bisa Anda gunakan hari ini

-

Kotak SKU campur: Pasangkan a paket es kering dari pertanian ke meja untuk protein dengan paket gel kecil yang menyangga sayuran.

-

Tidak ada genangan air: Es kering tidak memiliki air leleh; tambahkan bantalan penyerap hanya untuk tetesan produk.

-

Hindari kedap udara: Jahitan yang ditempel baik-baik saja; tambahkan jalur ventilasi kecil untuk mencegah tekanan.

Apakah paket es kering dari peternakan ke meja lebih baik daripada gel dan PCM?

Pilih berdasarkan rentang suhu dan risiko rute. Es kering menghasilkan suhu dingin yang intens lebih lama—cocok untuk protein dan makanan penutup beku. Kemasan gel berada pada suhu mendekati 0°C dan melindungi tekstur produk. PCM memiliki titik setel yang tepat; mereka bersinar ketika suatu produk tidak boleh berada di bawah titik beku.

| Opsi pendingin | Pita suhu yang khas | Tahan waktu (suka‑untuk‑suka) | Apa artinya bagimu |

|---|---|---|---|

| Paket es kering dari peternakan ke meja | ~−78,5°C sumber | Terpanjang per kg | Terbaik untuk protein tinggi atau panjang, rute panas |

| Paket gel | ~ 0 ° C. | Singkat | Ideal untuk sayuran dalam putaran pendek |

| PCMS | Titik setel khusus | Sedang | Cocok untuk spesifikasi sempit dan kontrol bergaya farmasi |

Jam es kering kotak terisolasi (isyarat cepat)

-

Kotak 22–28L yang terisolasi dengan baik dapat menampung 24–48H dengan kanan paket es kering dari pertanian ke meja.

-

Sublimasi yang khas adalah 5–10 lb per 24 H, tergantung pada isolasi dan beban panas.

-

Harapkan kehilangan lebih cepat dalam kotak tipis atau kotak bekas; tambahkan massa atau tingkatkan liner.

-

Muatan yang didinginkan sebelumnya mengurangi lonjakan suhu awal saat penyerahan.

Bagaimana Anda mengirimkan sesuai dan aman dengan paket es kering dari peternakan ke meja?

Ventilasi, label, dan melatih. Gunakan sarung tangan dan pelindung mata. Tandai “Es Kering (UN1845)” dan berat bersih dengan jelas. Simpan dan pindahkan di ruang yang berventilasi—pecahkan jendela van dan biarkan lorong tetap terbuka. Ikuti panduan es kering terbaru dari operator Anda untuk udara dan darat.

Beberapa operator menambahkan sensor CO₂ di dekat meja kemasan sebagai perlindungan berbiaya rendah. Simpan SOP dengan kontak darurat, keputusan rute yang terlambat, dan rencana tumpahan sederhana. Dokumentasikan massa es kering per kotak sehingga jalur audit tidak menimbulkan kesulitan.

Pertanian menghasilkan target suhu pengiriman (rentang sederhana)

| Produk | Targetkan pada saat kedatangan | Mengapa itu penting | Untuk kotakmu |

|---|---|---|---|

| Protein | ≤ −5°C (beku) | Tekstur, pengendalian patogen | Pasang di atas paket es kering dari pertanian ke meja |

| Sayuran hijau | 0–4 ° C. | kerenyahan, warna | Tetap di belakang penyekat |

| buah beri | 0–2°C | Pengurangan cetakan | Tambahkan buffer gel kecil |

Bagaimana Anda membuktikan paket es kering pertanian ke meja Anda berhasil?

Letakkan logger di kotak terhangat, menentukan batas lulus/gagal, dan meninjau setiap minggu. Titik hangat biasanya berada di pojok atas dekat penutup. Cicipi setiap lima menit. Spesifikasi Anda mungkin terbaca: “protein tetap berada pada suhu ≤ −5°C; menghasilkan 0–4°C pada saat kedatangan.” Kaitkan pengecualian dengan tindakan perbaikan untuk proses berikutnya.

Bagikan grafik sederhana kepada pelanggan setelah gelombang panas. Ini membangun kepercayaan dan mengurangi churn. Sebagian besar tim menstandarkan 2–3 “pemuatan” per rute dan melacak massa es kering, tahan waktu, jumlah pengaduan, dan tweak setiap hari Senin.

Metrik untuk ditinjau setiap minggu

-

ID rute, pengemudi, dan catatan cuaca

-

Massa es kering per kotak dan per batch

-

Tahan waktu (pengiriman ke depan pintu)

-

Pengecualian (klaim hangat, tetes terlambat)

-

Penyesuaian dilakukan untuk rute selanjutnya

2025 tren paket es kering dan rantai dingin dari pertanian ke meja

Operator melakukan standarisasi pemuatan, mengadopsi logger Bluetooth berbiaya rendah, dan beralih ke es kering‑CO₂ daur ulang. Pusat pemenuhan mikro menyusutkan jarak tempuh dan pengeluaran dry‑ice. Dapat digunakan kembali, liner high‑R dapat diambil di depan pintu, mengurangi pemborosan dan meningkatkan pengalaman pelanggan.

Apa yang baru, sekilas

-

Preset yang peka terhadap rute: Aplikasi pengepakan menyarankan hari ini paket es kering dari pertanian ke meja massa berdasarkan cuaca.

-

Pasokan CO₂ daur ulang: Kisah keren yang sama dengan tapak yang lebih rendah dapat Anda bagikan.

-

Kotak hibrida: Es kering untuk protein, gel untuk sayuran—lebih sedikit keluhan tekstur.

Wawasan pasar: Pelanggan mengharapkan sayuran segar, protein yang kuat, dan bersihkan unboxingnya. Pemenang menyederhanakan SKU per rute, kencangkan jendela paket, dan tunjukkan bukti suhu pasca pengiriman di portal.

Pertanyaan yang sering diajukan

Akankah paket es kering dari peternakan ke meja membekukan sayuran saya?

Simpan penyekat karton antara es kering dan hasil bumi, dan tambahkan paket gel kecil di sisi produk.

Berapa lama 1kg bertahan dalam kotak CSA?

Dengan liner yang pas dan kemasan yang nyaman, rencanakan pada 18–24 jam; cuaca panas mengurangi jendela itu.

Bisakah saya memasukkan es kering ke dalam pendingin kedap udara?

TIDAK. Co₂ harus melarikan diri. Gunakan jalur ventilasi atau tutup yang sedikit retak.

Label apa yang harus saya gunakan?

Tandai “Es Kering (UN1845)” dengan kilogram bersih, diposisikan agar pawang dapat melihatnya dengan segera.

Kapan gel lebih baik daripada paket es kering dari peternakan ke meja?

Putaran perkotaan pendek dengan muatan khusus produksi. Untuk kotak campuran atau banyak protein, gunakan hybrid atau es kering.

Ringkasan dan Rekomendasi

Poin -poin penting: Gunakan a paket es kering dari pertanian ke meja untuk penyimpanan yang lama atau muatan yang mengandung banyak protein. Kemas dengan langit-langit yang dingin, produksi penyangga, dan buka tutupnya. Ukur massa berdasarkan waktu rute, isolasi, dan volume. Buktikan kinerja dengan logger dan perbaiki masalah setiap minggu.

Langkah selanjutnya: Tentukan dua hingga tiga preset rute, pilih massa default, dan latih metode paket. Tambahkan ritual peninjauan hari Senin dan percontohan pasokan CO₂ daur ulang. Butuh bantuan? Pesan audit rute dan rencana pemuatan.

Tentang tempk

Kami menciptakan solusi rantai dingin yang praktis untuk merek makanan—mulai dari menyesuaikan ukuran produk Anda paket es kering dari pertanian ke meja untuk merancang stasiun paket yang berjalan cepat dan aman. Alat kami menstandarkan muatan es kering berdasarkan rutenya, melacak suhu secara otomatis, dan memotong limbah kemasan. Pelanggan melihat pengembalian hangat yang lebih sedikit dan proses membuka kemasan yang lebih bersih sekaligus menjaga rasa tetap utuh.

CTA: Bicaralah dengan tim kami untuk audit rute dan rencana pemuatan dengan ukuran yang tepat.