A sistem rantai dingin makanan lebih dari sekadar truk dan gudang berpendingin—ini adalah jaringan ujung ke ujung yang menjaga keamanan makanan yang mudah rusak dari pertanian hingga ke garpu. Di dalam 2025, peraturan yang lebih ketat, meningkatnya perdagangan lintas batas dan permasalahan iklim menjadikan penguasaan sistem ini penting. Pasar rantai makanan dingin global bernilai sekitar masuknya US$70,55 miliar 2025 dan diproyeksikan mencapai US$121,77 miliar pada 2030. Namun hingga 30 % makanan yang diproduksi untuk konsumsi manusia hilang atau terbuang, sering kali karena produk berada di zona bahaya suhu. Panduan ini menjelaskan cara kerja sistem rantai dingin pangan modern, menguraikan strategi desain, mengeksplorasi teknologi baru, dan memeriksa 2025 tren sehingga Anda dapat membangun ketahanan, rantai pasokan yang berkelanjutan.

Pahami dasar-dasar rantai dingin: Pelajari mengapa kontrol suhu sangat penting untuk keamanan pangan dan bagaimana zona suhu yang berbeda melindungi kualitas.

Merancang sistem yang efisien: Ikuti panduan langkah demi langkah tentang penilaian risiko, kemasan, desain penyimpanan, perencanaan dan pemantauan rute.

Manfaatkan teknologi: Lihat bagaimana IoT, Ai, blockchain dan energi terbarukan mengubah logistik rantai dingin.

Tetap terdepan dalam tren: Mengeksplorasi 2025 tren rantai dingin, mulai dari keberlanjutan dan ketahanan hingga pertumbuhan pasar dan wawasan regional.

Dapatkan tips praktis: Temukan rekomendasi yang dapat ditindaklanjuti, contoh dan FAQ yang disesuaikan dengan operasi Anda.

Apa Itu Sistem Rantai Dingin Pangan dan Mengapa Itu Penting?

Definisi dan pentingnya

A sistem rantai dingin makanan adalah serangkaian proses penyimpanan yang terkoordinasi, menangani dan mengangkut makanan yang mudah rusak dalam kisaran suhu tertentu. Kisaran ini—dinginkan (0–4 °C), beku (–16 °C hingga –20 °C) dan sangat beku (–28 °C hingga –30 °C)—Harus dijaga mulai dari produksi hingga konsumsi. Saat produk meninggalkan zona ini, bakteri seperti Salmonella atau E. coli dapat berkembang biak dengan cepat. Itu zona bahaya suhu antara 4 °C dan 60 ° C. mendorong pertumbuhan mikroba yang cepat; sehingga rantai dingin yang efektif mencegah penyakit yang ditularkan melalui makanan dan menghindari penarikan kembali yang mahal.

Selain kesehatan masyarakat, Kegagalan rantai dingin menimbulkan kerugian ekonomi dan lingkungan. Hingga sepertiga makanan yang diproduksi secara global terbuang sia-sia, dan sebagian besar kerugian ini terjadi karena barang disimpan pada suhu yang tidak tepat atau disimpan terlalu lama. Di negara berkembang, hingga 30 % produk yang mudah rusak hilang setiap tahunnya karena kontrol suhu yang tidak memadai selama transportasi. Inefisiensi ini meningkatkan emisi gas rumah kaca dan membebani rantai pasokan.

Penggerak peraturan

Pemerintah di seluruh dunia memperketat peraturan keamanan pangan. Itu KITA. Undang-Undang Modernisasi Keamanan Pangan (FSMA) Bagian 204 mewajibkan perusahaan yang menangani makanan berisiko tinggi untuk menyimpan catatan elektronik terperinci dan membagikannya kepada regulator pada bulan Januari 2026. Itu Hukum Pangan Umum Uni Eropa juga menekankan ketertelusuran dan pengendalian suhu. Di Tiongkok, Kementerian Perdagangan bertujuan untuk meningkatkan tingkat sirkulasi rantai dingin untuk buah-buahan, sayuran dan daging oleh 2027. Peraturan ini mendorong dunia usaha untuk meningkatkan peralatannya, mengadopsi pemantauan digital dan mendokumentasikan peristiwa pelacakan penting.

Prospek pasar

Pasar rantai makanan dingin berkembang pesat. Perkiraan bervariasi menurut perusahaan riset, namun konsensus menunjukkan adanya ekspansi yang kuat yang didorong oleh makanan siap saji, pengiriman bahan makanan e commerce dan perdagangan lintas batas:

Intelijen Mordor memperkirakan pasar pada masuknya US$70,55 miliar 2025, naik ke US$121,77 miliar pada 2030 (11.53 % CAGR). Produk dingin diperhitungkan 60 % pendapatan di 2024.

Riset Pasar Persistensi menempatkan 2025 pasar di US$65,8 miliar dan proyek US$205,3 miliar pada 2032 (17.5 % CAGR). Perintah Amerika Utara 32 % pangsa pasar, sementara Asia Pasifik adalah kawasan dengan pertumbuhan tercepat.

Logistik rantai dingin (penyimpanan dan transportasi) secara keseluruhan dihargai US$293,58 miliar masuk 2023 dan bisa mencapai US$862,33 miliar pada 2032 (13 % CAGR).

Angka-angka ini mencerminkan meningkatnya permintaan terhadap makanan beku, makanan olahan, obat-obatan dan produk segar. Mereka juga menyoroti peluang bagi dunia usaha untuk berinvestasi pada sistem rantai dingin dan memanfaatkan pertumbuhan.

Bagaimana Merancang Sistem Rantai Dingin Makanan Berkinerja Tinggi

Desain yang tepat memastikan rantai dingin Anda menjaga kualitas produk, memenuhi persyaratan peraturan dan beroperasi secara efisien.

Melangkah 1: Nilai produk dan risiko Anda

Mulailah dengan menganalisis persyaratan ketahanan dan suhu setiap produk. Petakan potensi risiko seperti waktu transit yang lama, kegagalan daya, kerusakan peralatan atau keterlambatan perbatasan. Evaluasi persyaratan peraturan—misalnya, FSMA 204 untuk makanan berisiko tinggi—dan rencanakan dengan tepat.

Melangkah 2: Pilih kemasan yang sesuai

Memilih kemasan yang tepat akan melindungi produk dari guncangan suhu. Solusi umum meliputi:

| Jenis kemasan | Fitur utama | Makanan yang cocok | Manfaat bagi Anda |

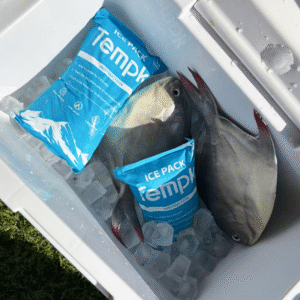

| Paket gel / batu bata es | Paket yang dapat digunakan kembali berisi gel atau air; membekukan padat dan mencair perlahan | Produk susu dingin, menghasilkan, daging | Berikan pendinginan yang konsisten; mudah ditangani; kombinasikan dengan kotak berinsulasi untuk pengiriman hemat biaya |

| Bahan perubahan fase (PCMS) | Bahan direkayasa untuk mempertahankan suhu tertentu (MISALNYA., 0 °C atau –20 °C) | Makanan siap saji, makanan laut bernilai tinggi | Pertahankan suhu yang tepat tanpa es kering; mengurangi berat pengiriman; dapat digunakan kembali |

| Es kering | Karbon dioksida padat (–78,5 °C); Sublimat ke gas | Daging beku, es krim, vaksin | Menyimpan barang di bawah –18 °C untuk waktu yang lama |

| Panel terisolasi vakum (VIP) | Panel insulasi berkinerja tinggi | Vaksin mRNA, makanan laut premium | Kinerja termal yang unggul; mengurangi berat dan ruang; sering digunakan dengan PCM |

| Penutup dan selimut palet termal | Penutup berinsulasi ditempatkan di atas palet | Menghasilkan, susu, minuman | Melindungi dari sinar matahari dan pancaran panas selama bongkar/muat |

| Wadah berpendingin aktif | Kontainer dengan unit pendingin internal yang ditenagai oleh baterai atau sumber eksternal | Pengiriman daging jarak jauh, hidangan laut, menghasilkan | Pertahankan suhu yang tepat terlepas dari kondisi sekitar; cocok untuk transportasi multi-hari atau internasional |

Melangkah 3: Desain fasilitas penyimpanan yang sesuai

Pisahkan gudang Anda menjadi beberapa zona untuk pendinginan, barang beku dan ambien untuk mencegah kontaminasi silang. Gunakan peralatan hemat energi dan pertimbangkan sumber energi terbarukan seperti panel surya. Dibangun agar sesuai dengan fasilitas penyimpanan dingin dan pusat pemenuhan mikro yang menempatkan inventaris lebih dekat dengan konsumen, mengurangi waktu transit dan penggunaan energi.

Melangkah 4: Rencanakan rute dan operator

Bermitra dengan operator yang menawarkan kendaraan dengan suhu terkendali dan rencana darurat yang tervalidasi. Gunakan perangkat lunak pengoptimalan rute yang mempertimbangkan lalu lintas, cuaca dan prioritas produk untuk mengurangi konsumsi bahan bakar dan waktu pengiriman. Logistik last mile merupakan tantangan; strategi seperti gudang kolaboratif, penggunaan kembali fasilitas lama dan bermitra dengan penyedia logistik pihak ketiga dapat meningkatkan efisiensi.

Melangkah 5: Menerapkan pemantauan dan penelusuran berkelanjutan

Lengkapi setiap pengiriman dengan sensor IoT dan pencatat data digital untuk mencatat suhu, kelembaban dan lokasi. Integrasikan data sensor dengan sistem manajemen transportasi (TMS), perencanaan sumber daya perusahaan (ERP) dan sistem manajemen gudang (WMS). Platform Blockchain menyediakan catatan bukti kerusakan yang mendukung audit dan manajemen penarikan kembali. Menurut Aliansi Rantai Dingin Global, lebih 70 % eksportir makanan di Amerika Utara dan Eropa menggunakan solusi pemantauan digital untuk memenuhi standar kepatuhan.

Melangkah 6: Melatih staf dan mengembangkan prosedur operasi standar

Memberikan pelatihan pengepakan, memuat, prosedur penanganan dan keadaan darurat. Tetapkan prosedur operasi standar yang menentukan pemeriksaan suhu dan tindakan perbaikan untuk tamasya. Tinjau SOP secara berkala untuk mencerminkan pembaruan peraturan dan perbaikan operasional.

Melangkah 7: Siapkan rencana darurat

Antisipasi keadaan darurat dengan memelihara pembangkit listrik cadangan, operator alternatif dan sensor cadangan. Jika pengiriman menyimpang dari suhu target, mengisolasi barang dan menghubungi jaminan kualitas untuk evaluasi. Pelacakan waktu nyata memungkinkan tindakan perbaikan sebelum kerusakan terjadi.

Tips dan nasihat praktis

Kalibrasi peralatan secara teratur: Verifikasi lemari es, akurasi freezer dan sensor setiap tiga bulan. Tempatkan pencatat digital secara terpusat di dalam wadah untuk melacak suhu produk sebenarnya.

Rencanakan pengemasan berdasarkan jenis makanan: Gunakan kemasan gel atau PCM untuk makanan dingin dan es kering atau pelat eutektik untuk makanan beku.

Kelola kelembapan dan aliran udara: Kelembapan yang tinggi mencegah dehidrasi pada sayuran berdaun hijau; ventilasi yang baik mengurangi kondensasi dan kontaminasi silang.

Latih staf dalam hal kebersihan: Minimalkan bukaan pintu dan ikuti rotasi masuk pertama keluar pertama; mendokumentasikan tindakan perbaikan untuk setiap perubahan suhu.

Memanfaatkan energi terbarukan: Pendinginan bertenaga surya dan forklift listrik mengurangi emisi karbon dan meningkatkan ketahanan.

Kasus nyata: Sebuah perusahaan logistik mengintegrasikan sensor IoT dengan sistem manajemen transportasinya, memberi klien visibilitas pengiriman secara real-time. Peringatan memberi tahu staf ketika suhu mendekati ambang batas kritis, Mengaktifkan tindakan korektif langsung. Sebagai akibat, biaya pembusukan menurun sebesar 15 % dan kepercayaan pelanggan meningkat.

Memanfaatkan Teknologi: Dari Sensor hingga AI

Kemajuan teknologi mengubah operasi rantai dingin. Alat-alat berikut tidak hanya membantu memenuhi persyaratan peraturan namun juga meningkatkan efisiensi dan keberlanjutan.

IoT, RFID dan GPS

Sensor IoT dan pencatat data mencatat suhu, kelembaban dan guncangan, mentransmisikan data waktu nyata ke dasbor cloud. Tag RFID mengotomatiskan pelacakan inventaris dan berintegrasi dengan sistem ERP/TMS. Pelacak GPS menyediakan data lokasi untuk optimasi rute dan bukti pengiriman. Bersama, perangkat ini memberi Anda visibilitas ujung ke ujung, mengurangi kesalahan manual dan memenuhi pelaporan peraturan.

Blockchain untuk ketertelusuran

Teknologi Blockchain menyimpan data suhu dan penyimpanan dalam buku besar anti rusak, memastikan integritas data untuk audit dan memfasilitasi penarikan kembali lebih cepat. Hal ini membangun kepercayaan di antara mitra dagang dan konsumen dengan memberikan bukti perjalanan suatu produk yang dapat diverifikasi.

Kecerdasan buatan dan analisis prediktif

AI menganalisis data sensor, cuaca dan lalu lintas untuk memprediksi kegagalan peralatan, memperkirakan permintaan dan mengoptimalkan rute. Pemeliharaan prediktif mengurangi waktu henti dengan mengidentifikasi kapan unit pendingin perlu diservis. Menurut Institut Makanan, AI akan mempengaruhi 90 % dari makanan yang kita konsumsi dengan mendorong efisiensi di seluruh rantai pasokan.

Otomatisasi gudang dan robotika

Robotika dan kendaraan berpemandu otomatis meningkatkan pengambilan, pengepakan dan penyortiran di fasilitas penyimpanan dingin. Otomatisasi mengurangi biaya tenaga kerja dan meminimalkan kesalahan, sementara AI mengoptimalkan tata letak gudang untuk pemanfaatan ruang.

Energi terbarukan dan teknologi hijau

Pendinginan bertenaga surya, truk listrik dan forklift berbahan bakar hidrogen mengurangi emisi karbon dan meningkatkan ketahanan. Itu Pindah ke koalisi –15 °C, diluncurkan pada 2023, mengusulkan menaikkan suhu beku standar dari –18 °C menjadi –15 °C. Pergeseran ini bisa saja terjadi menyimpan 17.7 juta ton CO₂, membuat penghematan energi sebesar 25 TWh dan memangkas biaya rantai pasokan sebesar 5–12 %. Uji coba menunjukkan bahwa menaikkan suhu mengurangi konsumsi energi freezer sebesar 10–11 % tanpa mengorbankan kualitas makanan.

Kiat implementasi

Mulailah dari yang kecil: Sensor percontohan dan pemantauan digital pada sebagian kecil pengiriman untuk memvalidasi kinerja sebelum melakukan penskalaan.

Integrasikan aliran data: Hubungkan sensor IoT, TMS, ERP dan WMS untuk melihat rantai pasokan Anda dalam satu dasbor.

Melatih dan memberdayakan staf: Berikan pelatihan tentang aplikasi seluler, menafsirkan peringatan dan merespons kunjungan.

Rencanakan keamanan siber: Lindungi data dengan mengenkripsi komunikasi, memperbarui firmware dan menggunakan jaringan aman.

Pantau laba atas investasi: Ukur manfaat seperti berkurangnya pembusukan, biaya energi yang lebih rendah dan peningkatan kepatuhan untuk membenarkan investasi yang berkelanjutan.

2025 Tren yang Membentuk Sistem Rantai Dingin Pangan

Lanskap rantai dingin berubah dengan cepat. Memahami tren yang muncul membantu bisnis merencanakan investasi, mengurangi risiko dan menangkap peluang.

Keberlanjutan dan efisiensi energi

Konsumsi energi merupakan perhatian utama untuk makanan beku. Inisiatif Menuju –15 °C yang disebutkan sebelumnya menunjukkan caranya sedikit meningkatkan suhu freezer dapat menghemat energi dan mengurangi emisi CO₂. Praktik yang lebih ramah lingkungan—termasuk pencahayaan LED, integrasi tenaga surya dan material berkelanjutan—bisa mengurangi biaya energi hampir 50 %. Operator berinvestasi pada pusat pemenuhan mikro dan teknologi pengurangan karbon untuk memenuhi harapan konsumen akan logistik berkelanjutan.

Pertumbuhan pasar dan investasi

Permintaan terhadap cold storage meningkat. Daerah dengan pertumbuhan tinggi seperti Texas, Florida dan Georgia bertanggung jawab 47 % perkembangan penyimpanan dingin baru sejak itu 2020. Investasi dalam real estat penyimpanan dingin menarik karena fasilitasnya memerlukan harga sewa yang premium; rata-rata harga sewa yang diminta telah meningkat lebih dari 96 % sejak 2019. Fasilitas penyimpanan dingin rata-rata adalah 42 tahun, dan lebih dari setengahnya telah berakhir 30 tahun, mendorong proyek modernisasi. Pengembang sedang membangun gudang penyimpanan dingin yang spekulatif untuk memenuhi permintaan, sementara operator menggunakan kembali fasilitas lama dengan teknologi modern.

Pola konsumsi dan keragaman produk

Preferensi konsumen terhadap makanan segar, makanan yang bersumber secara lokal, perlengkapan makan dan produk organik membentuk kembali penyimpanan dingin. Fasilitas meningkatkan kapasitas produksi, perlengkapan susu dan makanan, dan mereka harus menangani lebih banyak barang yang sensitif terhadap suhu. Alternatif nabati dan produk bebas gluten semakin populer; makanan nabati dapat menjelaskan hal ini 7.7 % pasar protein global (lebih dari US$162 miliar) oleh 2030. Produk-produk ini memerlukan penanganan khusus dan sering kali diproduksi oleh usaha kecil dan menengah yang mencari penyedia logistik rantai dingin yang ahli.

Otomatisasi dan digitalisasi

Otomatisasi dan digitalisasi mendorong efisiensi dan penghematan biaya. Fasilitas modern mengintegrasikan sistem pengambilan otomatis, kontrol suhu tingkat lanjut dan robotika. Platform visibilitas digital memungkinkan akses data tanpa gangguan di seluruh rantai pasokan dan membantu bisnis merespons gangguan dengan cepat. Operator cold chain berinvestasi pada perangkat lunak untuk meningkatkan visibilitas dan ketahanan.

Modernisasi infrastruktur dan tekanan peraturan

Fasilitas penyimpanan dingin semakin tua—banyak yang dibangun 40–50 tahun yang lalu. Meningkatkan fasilitas-fasilitas ini sangat penting untuk efisiensi dan kepatuhan terhadap peraturan. Konstruksi baru menekankan otomatisasi, Keberlanjutan, visibilitas yang ditingkatkan dan integrasi yang lebih baik. Peraturan juga menghapuskan secara bertahap zat pendingin berbahaya seperti HCFC dan HFC. Sistem modern menggunakan zat pendingin alami (Co₂, amonia) dan teknologi hemat energi, mengurangi emisi dan biaya operasional.

Perluasan pasar dan dinamika regional

Ekspor pangan yang mudah rusak meningkat 5.6 % setiap tahun antara 2018 Dan 2023, dengan Asia Pasifik dan Amerika Latin yang mendorong pertumbuhan. Kapasitas gudang berpendingin di India meningkat 35 % di antara 2020 Dan 2024, sementara kapasitas Tiongkok melebihi 200 juta meter kubik. Amerika Utara bertahan 31–32 % dari pangsa pasar global, namun Asia Pasifik adalah kawasan dengan pertumbuhan tercepat berkat investasi pada cold storage dan pengiriman makanan melalui e-commerce. Negara-negara berkembang seperti India, Indonesia dan Vietnam mengalami pertumbuhan dua digit, didukung oleh insentif pemerintah dan investasi asing langsung.

Mengurangi limbah makanan dan meningkatkan transparansi

Pelacakan waktu nyata dan sensor IoT membantu mengurangi limbah makanan dengan memastikan produk dikirimkan dalam kondisi optimal. Konsumen semakin menuntut transparansi; menyediakan data kesegaran mendorong konsumsi tepat waktu dan mengurangi limbah rumah tangga. Platform digital memungkinkan pelanggan melacak perjalanan makanan mereka, membangun kepercayaan dan membedakan merek.

Logistik rantai dingin selain makanan

Sedangkan panduan ini fokus pada makanan, sistem rantai dingin juga mendukung farmasi, bioteknologi dan sektor sensitif suhu lainnya. Pasar rantai dingin farmasi global diproyeksikan akan tercapai US$1.454 miliar pada 2029 dengan CAGR sebesar 4.71 %. Pertumbuhan dalam distribusi vaksin dan biologi menggarisbawahi perlunya jaringan rantai dingin yang terintegrasi.

FAQ (Pertanyaan yang sering diajukan)

Q1: Pada suhu berapa saya harus menyimpan daging segar dan makanan laut?

Daging segar dan makanan laut harus disimpan di antaranya 0 °C dan 4 ° C. untuk memperlambat pertumbuhan bakteri. Untuk pengiriman lebih dari dua hari, gunakan paket gel atau bahan pengubah fasa untuk menjaga suhu.

Q2: Bagaimana FSMA 204 mempengaruhi operasi saya?

FSMA 204 mewajibkan perusahaan yang menangani makanan berisiko tinggi untuk mencatat peristiwa pelacakan penting dan membagikannya secara elektronik kepada regulator pada bulan Januari 2026. Anda perlu menerapkan pemantauan digital, mengintegrasikan sensor dengan sistem inventaris dan melatih staf dalam penanganan dan pelaporan data.

Q3: Apa yang dimaksud dengan inisiatif Pindah ke –15 °C?

Koalisi Pindah ke –15 °C mengusulkan peningkatan suhu penyimpanan makanan beku standar dari –18 °C menjadi –15 °C. Penelitian menunjukkan bahwa perubahan ini bisa terjadi menyimpan 17.7 juta ton CO₂, menghasilkan 25 TWh penghematan energi dan menurunkan biaya hingga 12 %. Uji coba menunjukkan a 10–11 % pengurangan konsumsi energi freezer tanpa mengorbankan kualitas makanan.

Q4: Bagaimana pelacakan waktu nyata dapat mengurangi limbah makanan?

Sensor IoT dan pemantauan GPS menyediakan data suhu dan lokasi secara berkelanjutan. Jika suhu mendekati ambang batas kritis, peringatan memberi tahu staf untuk mengambil tindakan perbaikan, mencegah pembusukan. Menurut Institut Pangan, pelacakan waktu nyata membantu mengirimkan produk dalam kondisi optimal dan mengurangi limbah makanan.

Q5: Apa manfaat energi terbarukan dalam rantai dingin?

Sumber energi terbarukan seperti tenaga surya dan angin mengurangi emisi karbon, menurunkan biaya operasional dan meningkatkan ketahanan terhadap pemadaman listrik. Mengintegrasikan panel surya dengan unit pendingin dan menggunakan kendaraan listrik mengurangi ketergantungan pada bahan bakar fosil dan membantu mencapai tujuan ESG.

Ringkasan dan Rekomendasi

Kunci takeaways

Pertahankan suhu yang benar: Simpan barang dingin di 0–4 °C, barang beku di –16 °C hingga –20 °C dan barang beku di –28 °C hingga –30 °C. Hindari zona bahaya (4–60 °C) dimana bakteri berkembang biak dengan cepat.

Berinvestasi dalam pemantauan digital: Lebih 70 % eksportir di wilayah maju sudah menggunakan sensor IoT dan pemantauan digital untuk memenuhi standar kepatuhan. Menerapkan sensor, RFID dan blockchain untuk visibilitas dan ketertelusuran ujung ke ujung.

Manfaatkan AI dan otomatisasi: AI meningkatkan perencanaan rute, pemeliharaan prediktif dan optimalisasi gudang. Otomatisasi mengurangi biaya tenaga kerja dan kesalahan.

Mengadopsi praktik berkelanjutan: Bergabunglah dengan inisiatif seperti Menuju suhu –15 °C dan berinvestasi pada mesin pendingin bertenaga terbarukan dan kemasan yang dapat digunakan kembali. Praktik yang lebih ramah lingkungan bisa mengurangi biaya energi hingga hampir mencapainya 50 %.

Bangun ketahanan: Melakukan penilaian risiko, pilih operator yang dapat diandalkan, menerapkan pelacakan waktu nyata dan memelihara rencana darurat untuk menangani gangguan.

Rencana aksi

Audit rantai dingin Anda saat ini: Identifikasi titik lemah, perjalanan suhu dan limbah. Petakan rantai pasokan Anda untuk memahami aliran produk dan risikonya.

Tingkatkan peralatan dan pemantauan: Pasang sensor IoT, pencatat data digital dan platform perangkat lunak terintegrasi untuk mendapatkan visibilitas waktu nyata. Mulailah dengan proyek percontohan dan skalakan secara bertahap.

Latih tim Anda: Mengembangkan SOP dan melatih staf dalam pengepakan, penanganan, interpretasi data dan tanggap darurat.

Berkolaborasi dengan mitra yang dapat diandalkan: Pilih operator dan mitra gudang yang menawarkan kontrol suhu tervalidasi dan rencana darurat. Jelajahi kemitraan dengan penyedia logistik pihak ketiga untuk pengoptimalan jarak jauh.

Berinvestasi dalam keberlanjutan: Menggabungkan energi terbarukan, teknologi hemat energi dan kemasan yang dapat digunakan kembali. Berpartisipasilah dalam inisiatif industri seperti Peralihan ke –15 °C untuk mengurangi emisi.

Rencanakan pertumbuhan: Mengawasi tren pasar seperti otomatisasi, produk nabati dan ekspansi regional. Memodernisasi fasilitas yang sudah tua dan berinvestasi di pusat pemenuhan mikro agar tetap kompetitif.

Tentang tempk

Pada Tempk, kami berspesialisasi dalam solusi rantai dingin yang komprehensif untuk industri makanan. Tim kami menggabungkan pengalaman puluhan tahun dengan teknologi mutakhir untuk menghasilkan sistem pengemasan yang tervalidasi, fasilitas penyimpanan cerdas dan platform pemantauan waktu nyata. Kami membantu Anda memenuhi peraturan ketat seperti FSMA 204 dengan mengintegrasikan sensor IoT, blockchain dan AI ke dalam operasi Anda. Solusi berkelanjutan kami mencakup pendinginan bertenaga surya, gudang hemat energi dan kemasan yang dapat digunakan kembali, mengurangi jejak karbon Anda sekaligus menjaga produk tetap aman. Apakah Anda seorang produser, distributor atau pengecer, kami menyesuaikan layanan kami dengan kebutuhan unik Anda.

Panggilan untuk bertindak: Siap mengubah sistem rantai dingin makanan Anda? Kontak Tempkpakar kami untuk penilaian yang dipersonalisasi dan temukan bagaimana kami dapat mengoptimalkan operasi Anda demi keselamatan, keberlanjutan dan profitabilitas