Lembar paket es kering yang dapat digunakan kembali: 2025 Panduan Pembeli

Lembaran kantong es kering yang dapat digunakan kembali membantu Anda menahan suhu 2–8°C dengan andal, memotong kebocoran, dan menghindari dokumen barang berbahaya. Gunakan untuk jalur yang dingin dan agak beku; beralihlah ke es kering asli untuk suhu ≤−60°C atau lama, rute yang rawan penundaan. Suhu es kering adalah −78,5°C dan memerlukan pelabelan UN1845/PI954 serta kemasan berventilasi; lembaran adalah gel polimer terhidrasi yang Anda rendam, membekukan, dan menggunakan kembali.

Terakhir diperbarui: September 2, 2025

-

Kapan lembaran kantong es kering yang dapat digunakan kembali merupakan pilihan yang lebih baik untuk perlengkapan makan, hidangan laut, kosmetik, dan farmasi 2–8°C.

-

Ketika es kering asli adalah wajib dan tanda PI954/UN1845 mana yang paling penting.

-

Berapa banyak lembar yang Anda butuhkan dengan kalkulator cepat dan tip validasi.

-

Cara berkemas untuk kunjungan yang lebih sedikit menggunakan spacer sederhana, liner, dan pencatat data.

Bagaimana cara kerja lembaran kantong es kering yang dapat digunakan kembali pada suhu 2–8°C?

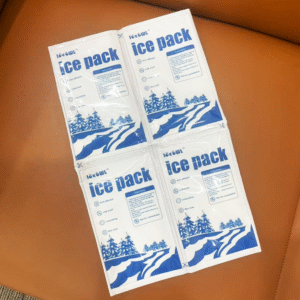

Jawaban singkat: Lembaran kantong es kering yang dapat digunakan kembali adalah “selimut es” gel yang dapat dihidrasi,” bukan CO₂ padat. Anda berendam, membekukan, dan menggunakannya kembali untuk menghasilkan hasil yang stabil, keringkan dingin selama 24–72 jam dalam paket terisolasi. Itu membuat makanan dan produk kesehatan berada di zona aman tanpa label hazmat. Es kering asli ditujukan untuk suhu yang sangat dingin.

Dalam praktiknya: Anda menghidrasi lembaran 2–5 menit, keringkan, dan bekukan rata 12–18 jam. Banyaknya sel kecil menyimpan “energi dingin” dan melepaskannya secara perlahan, seperti baterai, menjaga paket Anda pada suhu sekitar 2–8°C. Jika jalur Anda membutuhkan pembekuan yang lebih lembut, tambahkan lebih banyak lembaran dan tingkatkan insulasi; untuk ≤−60°C, pilih es kering dan ikuti aturan penerimaan. Panduan keamanan pangan lebih mengutamakan kemasan gel untuk pengiriman dingin dan pemeriksaan termometer pada saat kedatangan.

Lapisan es yang dapat terhidrasi: pengaktifan & tip pembekuan

Hidrasi sampai sel membengkak secara merata, lalu bekukan pada suhu −10 hingga −20°C di dalam nampan agar lembaran tetap rata. Dinginkan produk Anda terlebih dahulu (MISALNYA., 34–36°F untuk makanan) dan isolasi benda-benda halus dengan bantalan bergelombang untuk menghindari “luka bakar dingin”. Langkah-langkah ini memperpanjang waktu penahanan dan melindungi tekstur sensitif.

| Pilihan pendingin | Apa itu | Kisaran khas | Apa artinya bagimu |

|---|---|---|---|

| Lembaran kantong es kering yang dapat digunakan kembali | Sel gel polimer yang dapat terhidrasi | 2–8 ° C., beku ringan | Membersihkan, dapat digunakan kembali, tidak ada dokumen DG—ideal untuk bahan makanan dan D2C. |

| Es kering asli (UN1845) | CO₂ padat pada suhu −78,5°C | ≤−60°C tahan | Kekuatan ultra-dingin; memerlukan label PI954 dan kemasan berventilasi. |

| 2–8°C panel PCM | Paket perubahan fase titik setel | 72–120 jam dengan VIP | Kontrol yang paling ketat terhadap vaksin/biologis; capex yang lebih tinggi, dapat digunakan kembali. |

Tips praktis yang bisa Anda terapkan hari ini

-

Kit makan (30–48H): atas & lapisan lembaran bawah; daging di dekat sumber dingin, sayuran terpusat; periksa langsung ≤40°F pada tanda terima.

-

Cokelat di musim panas: tambahkan lapisan foil untuk mengurangi pancaran panas dan bantalan atas untuk mencegah bekas beku.

-

Hidangan laut (2‑udara siang hari): dua lapisan lembaran ditambah lapisan penyerap; catat tiga putaran pertama dan setel jumlah lembar sebanyak ±1.

Kasus nyata: Sebuah toko roti mengganti es lepas dengan lembaran bungkus es kering yang dapat digunakan kembali pada jalur 2 hari dan menampung kedatangan pada suhu 36–41°F sekaligus menghilangkan pengembalian kotak yang basah—tidak ada desain ulang karton, hanya paket yang disiplin.

Kapan lembaran kantong es kering yang dapat digunakan kembali lebih baik daripada es kering?

Gunakan lembaran kantong es kering yang dapat digunakan kembali untuk pengiriman dengan suhu terkendali 2–8°C atau dalam kondisi beku ringan yang diberi label hazmat, ventilasi, dan penandaan net‑kg akan memperlambat pengoperasian. Gunakan es kering asli ketika spesifikasi produk memerlukan ≤−60°C atau Anda memerlukan buffer yang panjang untuk penundaan. Perpecahan “dingin vs ultra‑dingin” ini selaras dengan 2025 panduan pembawa dan keamanan pangan.

Mengukur lembaran kantong es kering yang dapat digunakan kembali—kalkulator cepat

Gunakan perkiraan first‑pass ini, kemudian validasi dengan data logger (Gaya ISTA 7D/7E):

# Seprai dibutuhkan dengan a 20% penyangga

memuat_Wh = kotak_U_W_per_C * delta_T * durasi_h

lembar = bulat(memuat_Wh / lembar_pendinginan_Wh * 1.2)

mencetak(lembaran)

Mengapa ini membantu: Anda mencocokkan perolehan panas yang diharapkan dengan kapasitas lembaran, lalu membuktikannya di jalur terburuk di profil musim panas/dingin. ISTA 7E direferensikan secara luas untuk pengujian termal paket di 2025.

Paket lembaran es kering yang dapat digunakan kembali: Petunjuk langkah demi langkah

Jawab dulu: Produk pra-kondisi, lembaran hidrat/beku, lapisan atas & dasar, tambahkan pengatur jarak, dan verifikasi dengan logger. Hal ini mencapai target suhu dan mengurangi pengembalian.

-

Prasyarat produk hingga 2–8°C.

-

Hidrat lembar 2–5 menit; keringkan.

-

Membekukan datar 12–18 jam pada suhu −10 hingga −20°C.

-

Mengemas: lapisan lembaran bawah → produk dalam baki → lapisan lembaran atas.

-

Menambahkan liner penyerap dan logger inti.

-

Segel dan uji goyang untuk menghilangkan rongga.

Hindari kerusakan akibat pembekuan dengan lembaran kantong es kering yang dapat digunakan kembali

Jauhkan makanan rapuh dan kosmetik yang sensitif terhadap suhu dari kontak langsung dengan permukaan yang beku. Tambahkan bantalan bergelombang atau pelapis gelembung untuk meredakan rasa dingin. Targetkan suhu ≤40°F saat pengantaran makanan; probe sederhana berfungsi.

Lembaran kantong es kering yang dapat digunakan kembali vs es kering: cuplikan kepatuhan

Intinya: Seprai bebas bahan hazmat; es kering adalah Kelas 9 (UN1845) dan harus memenuhi PI954. Tandai nama pengiriman yang benar, Nomor PBB, Kg net, tempatkan Kelas 9 label pada permukaan yang sama, dan memastikan ventilasi. Alat bantu pekerjaan operator masuk 2025 tekankan penempatan label dan berat bersih di luar berlian.

Daftar periksa siap salin (es kering saja):

-

Nama yang tepat: “Es kering” atau “karbon dioksida, padat."

-

UN1845 & Kelas 9 label, permukaan yang sama.

-

Berat bersih es kering (kg), ditandai dengan jelas.

-

Kemasan ventilasi; jangan pernah menyegel es kering dalam lapisan kedap udara.

2025 tren lembaran paket es kering dan PCM yang dapat digunakan kembali

Tinjauan Tren: Maskapai penerbangan dan integrator memperketat penerimaan PI954 detail, sementara profil ISTA 7E mendapatkan daya tarik untuk pengujian parsel. Sistem VIP+PCM memperpanjang suhu 2–8°C hingga 96–120 jam, Tetapi lembaran kantong es kering yang dapat digunakan kembali tetap yang paling sederhana, garis dasar yang dapat digunakan kembali untuk sebagian besar jalur D2C yang dingin.

Terbaru dalam sekejap

-

Alat bantu kerja PI954 yang lebih jelas: tanda standar, penekanan net‑kg, pengingat ventilasi.

-

Pergeseran standar parsel: lebih banyak jalur yang divalidasi terhadap ISTA 7E; perbandingan apel-ke-apel yang lebih mudah.

-

Pertumbuhan VIP+PCM: beberapa hari suhu 2–8°C bertahan (>5 hari dalam beberapa kit yang memenuhi syarat) untuk beban bernilai tinggi.

Wawasan pasar: Untuk non-farmasi, operator masih meringkasnya secara sederhana—gel/lembaran untuk dingin, es kering untuk beku—sebuah aturan yang diterapkan dengan baik pada bahan makanan dan perlengkapan makan sehari-hari.

Pertanyaan yang sering diajukan

Q1: Apakah lembaran kantong es kering yang dapat digunakan kembali sebenarnya adalah es kering?

TIDAK. Ini adalah lembaran gel polimer yang dapat dihidrasi—bebas bahan berbahaya kecuali Anda menambahkan es kering asli.

Q2: Berapa suhu pengiriman yang harus saya targetkan untuk makanan?

Targetkan suhu ≤40°F (4 ° C.) pada saat kedatangan; verifikasi dengan termometer.

Q3: Apakah saya memerlukan label hazmat jika saya hanya menggunakan lembaran saja?

TIDAK. Hazmat berlaku untuk CO₂ padat. Jika Anda menambahkan es kering, ikuti PI954 dengan UN1845, Net - kg, penempatan label, dan ventilasi.

Q4: Berapa banyak lembar kantong es kering yang dapat digunakan kembali yang saya perlukan?

Gunakan kalkulator di atas sebagai titik awal, kemudian uji coba dengan data logger di jalur paling berisiko Anda dan sesuaikan.

Q5: Kapan saya harus beralih ke panel PCM?

Gunakan PCM 2–8°C + VIP saat Anda memerlukan penahanan 96–120 jam dan rentang suhu yang lebih ketat untuk farmasi/biologi yang tervalidasi.

Ringkasan & Rekomendasi

Rekap: Lembaran kantong es kering yang dapat digunakan kembali menangkan suhu 2–8°C dan pengiriman beku yang lembut—bersih, dapat digunakan kembali, dan kepatuhan yang ringan. Es kering menutupi suhu ≤−60°C dan jalur padat penundaan tetapi menuntut disiplin PI954. Validasi dengan profil ISTA, jumlah lembar lagu berdasarkan musim, dan menambahkan spacer untuk melindungi barang sensitif.

Langkah selanjutnya (CTA):

-

Tentukan jalur Anda (2–8°C vs sangat dingin).

-

Gunakan kalkulator ukuran; menjalankan tiga pilot berinstrumen.

-

Kunci SOP (waktu hidrasi, membekukan waktu, jumlah lembar musiman).

-

Membutuhkan matriks paket khusus jalur? Permintaan Tempk gratis 2025 matriks berdasarkan waktu pemberhentian dan waktu tunggu Anda.

Tentang tempk

Kami adalah tim teknik rantai dingin yang berfokus pada paket tervalidasi, Desain VIP+PCM, dan kepatuhan Ditjen. Kami membantu merek mengurangi kunjungan dan menyederhanakan audit. Dua keuntungan nyata: (1) alat khusus jalur dengan ukuran yang tepat lembaran kantong es kering yang dapat digunakan kembali penting; (2) program es kering siap pakai dengan label otomatis dan pelacakan kg bersih. Bicaralah dengan spesialis untuk menyesuaikan matriks paket untuk rute Anda.