Kotak Busa EPP Tahan Guncangan: 2025 Memandu?

A shock resistant EPP foam box helps you ship fragile or temperature-sensitive products with fewer “surprise breaks.” It absorbs drops, calms vibration, and resists crushing—while staying light and reusable. In molded EPP parts, thermal conductivity is often reported around 0.036–0.046 W/(m·K), and water absorption is commonly described as very low (sering <1 vol-%), which matters when condensation is real.

Artikel ini akan menjawabnya untuk Anda:

-

Bagaimana a shock resistant EPP foam box prevents damage in real handling

-

Yang EPP foam box density and wall thickness choices matter most

-

Cara menjalankan a shock resistant EPP foam box drop test plan Anda bisa mengulanginya

-

Ketika sebuah shock resistant EPP foam box for cold chain delivery makes sense

-

Bagaimana cara mengelolanya siklus kembali without performance drifting

-

How to estimate total cost per trip (bukan hanya harga kotak)

What Is a Shock Resistant EPP Foam Box?

A shock resistant EPP foam box is a molded container made from expanded polypropylene (EPP) that cushions impacts and keeps its shape after repeated hits. If you want the simplest picture, itu a springy helmet for your product: it compresses on impact, spreads the force, and rebounds.

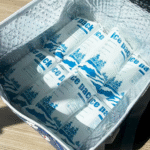

shock resistant EPP foam box

Your biggest win is not “thicker foam.” Your biggest win is stable fit—the box holds the payload still, so it can’t rattle itself into failure.

Why “Fit First” is the fastest upgrade

If your payload can move, it will move—especially during vibration. A snug cavity plus the right insert often beats adding more thickness.

| Fit decision | What happens in transit | What you see later | Apa artinya bagimu |

|---|---|---|---|

| Loose cavity | payload “walks” | cracked corners, lecet | higher return rate |

| Snug cavity | movement stays low | fewer DOA complaints | steadier quality |

| Nyaman + menyisipkan | corners protected | fewer “mystery breaks” | klaim yang lebih sedikit |

Tip dan rekomendasi praktis

-

Shake test: if it rattles, your cavity is too loose—add inserts or adjust the design.

shock resistant EPP foam box

-

Corner focus: corners take the first hit on real routes.

-

Disiplin tutup: a great box fails if the lid shifts.

How Does a Shock Resistant EPP Foam Box Prevent Damage?

A shock resistant EPP foam box protects against three everyday hazards: tetes, getaran, dan kompresi. Most teams plan for one drop. Real networks deliver many small hits plus occasional big ones.

Think “egg in a helmet.” The helmet spreads the hit so the egg doesn’t crack.

| Impact type | Apa penyebabnya | How a shock resistant EPP foam box helps | Manfaat praktis Anda |

|---|---|---|---|

| Menjatuhkan | penanganan, terakhir mil | absorbs peak force | retakan yang lebih sedikit |

| Getaran | long transport | dampens movement | less fatigue damage |

| Kompresi | stacking loads | holds structure | fewer crushed corners |

Thickness vs density: which matters more?

Thickness helps, but density often decides whether foam bottoms out. Too soft and you hit the “floor.” Too stiff and the shock transmits through.

| Design lever | If it’s too low | If it’s too high | The balance you want |

|---|---|---|---|

| Kepadatan | bottoms out on hard drops | transmits shock | firm-but-springy |

| Ketebalan dinding | penyok, heat leaks | wasted space/weight | route-matched |

| Geometri sudut | corners crack first | heavy/overbuilt | sudut yang diperkuat |

Practical scenario guidance

-

Rentan + lampu: prioritize softer inserts and snug fit.

-

Heavy payload: prioritize a stronger base and ribs.

-

Pallet shipping: prioritize corner reinforcement and stacking stability.

Practical case pattern: Many breakage reductions come from tighter cavity fit plus separators, not thicker walls.

shock resistant EPP foam box

How Do You Choose Shock Resistant EPP Foam Box Density and Wall Thickness?

Memilih a shock resistant EPP foam box is a balancing act between cushioning and support. Density influences stiffness. Thickness adds both impact travel distance and thermal buffer.

Tujuannya sederhana: protect the payload without over-designing.

A quick density-and-thickness starting point

Use this as a starting logic, then confirm with testing.

| Muatan + jalur | Density direction | Wall direction | Apa artinya bagimu |

|---|---|---|---|

| Lampu + rentan (elektronik) | lower-to-mid | sedang | lower peak shock |

| Berat + tahan lama (parts) | mid-to-higher | lebih tebal + tulang rusuk | prevent sag/crush |

| Cold chain + rentan | campur aduk (kotak + menyisipkan) | lebih tebal | Lindungi suhu + dampak |

| High reuse program | pertengahan + reinforced geometry | stabil | kinerja yang konsisten |

A 90-second decision tool (score 0–10)

Berikan dirimu sendiri 1 titik untuk setiap “Ya”:

-

Your packages go through parcel networks with many transfers.

-

You already see corner crush or lid pop-offs.

-

Your product is fragile or calibration-sensitive.

-

Weight is concentrated in a small area.

-

You ship in hot weather or long routes.

-

Multi-stop delivery is common.

-

Stacking pressure happens during storage or transit.

-

Your claim cost is high (penggantian + tenaga kerja).

-

You want to reuse packaging.

-

You need both insulation and shock control.

Arti skor

-

0–3: Basic shock resistant EPP foam box may work; focus on fit and closure.

-

4–7: Add inserts, stronger corners, and validation testing.

-

8–10: Treat the shock resistant EPP foam box as an engineered system.

How Do You Test a Shock Resistant EPP Foam Box for Shipping?

A shock resistant EPP foam box is only “proven” when you test the full system: kotak + menyisipkan + muatan + penutup + packing method. That is where most failures hide.

For parcel-style lanes, ISTA 3A is commonly used. For broader distribution simulation, many teams use ASTM D4169 schedules. ISO also provides methods like Iso 2248 for vertical impact (menjatuhkan) tes. ASTM D4169 also saw a notable update in 2024 (often referenced as D4169-23e1), so align on the current version before validating.

shock resistant EPP foam box

Fast test plan template you can copy

-

Tentukan jalurnya: paket, Ltl, udara, ekspor, warehouse stacking.

-

Pick the test family: ISTA 3A (paket) or ASTM D4169 (broader cycles).

-

Set pass/fail rules: function, kebocoran, cosmetic limits, closure integrity.

-

Test multiple samples: 2–5 units if fragile or high value.

-

Document “as packed”: foto, insert placement, metode penutupan, logger location.

shock resistant EPP foam box

| Tes | What it reveals | Where a shock resistant EPP foam box fails | What you improve |

|---|---|---|---|

| Menjatuhkan | corner/edge weakness | cracked corners, lid shift | stronger corners, better closure |

| Getaran | loose fit | payload “walks” | tighter insert, anti-slip |

| Kompresi | stacking collapse | wall buckling | tulang rusuk, stronger base |

Tip dan rekomendasi praktis

-

Test corners first. Corners fail before flat faces.

-

Repeat drops. One drop can be luck; repeats show durability.

-

Test after reuse. Dents and wear change performance.

shock resistant EPP foam box

Practical case pattern: It’s common to “pass drops” but fail vibration because the payload migrates.

shock resistant EPP foam box

Can a Shock Resistant EPP Foam Box Support Cold Chain Delivery?

Ya. A shock resistant EPP foam box can work well for cold chain because EPP is insulating and stays stable after impacts. But insulation is not magic. Hold time depends on lid seal quality, celah udara, ketebalan dinding, coolant type (Paket gel, PCM, es kering), kondisi sekitar, and trip duration.

shock resistant EPP foam box

If your lid fit is loose, seal beats thickness—fix closure before adding material.

shock resistant EPP foam box

Cold chain packing layout that protects impact and temperature

| Payload type | Penempatan cairan pendingin | Insert strategy | Apa artinya bagimu |

|---|---|---|---|

| Makanan dingin | atas + sisi | corner bumpers | fewer bruises/leaks |

| Barang beku | mengelilingi + basis | firm base support | less thaw at corners |

| Lab/pharma samples | balanced packs | precision insert | suhu stabil + terkejut |

Moisture management rules (sederhana dan efektif)

-

Dry boxes before storage. Trapped moisture becomes odor.

-

Avoid tape residue on foam surfaces; it traps dirt.

-

Use removable liners for “leak risk” lanes to cut cleaning time.

shock resistant EPP foam box

How Many Reuse Cycles Can a Shock Resistant EPP Foam Box Handle?

A shock resistant EPP foam box is built for reuse, but real life sets the limit. Reuse cycles depend on handling intensity, metode pembersihan, and corner impacts.

shock resistant EPP foam box

Treat the box like an asset. Track it, inspect it, and retire it when it fails.

Simple inspection rules for reuse programs

| Check point | What you look for | Pass standard | Apa artinya bagimu |

|---|---|---|---|

| Corners | hancur, torn foam | rebounds + holds shape | drop protection remains |

| Lid fit | loose engagement | closes tight | lebih sedikit tumpahan + heat leaks |

| Interior | deep gouges | wipe-clean surface | easier sanitation |

| Basis | melengkung | flat stability | safe stacking |

A fast “Green / Yellow / Red” grading system

-

Hijau: ready for next trip.

-

Yellow: use for lower-risk lanes; monitor closely.

-

Merah: retire or repair (jangan kirim).

Tip operasional: Add a 10-second corner-and-lid check at receiving to prevent next-trip failures.

Is a Shock Resistant EPP Foam Box Worth the Cost?

A shock resistant EPP foam box often wins on biaya per pengiriman yang berhasil, bukan harga beli. If it reduces damage and lasts many cycles, total cost can drop.

Kalkulator mini: biaya per perjalanan (interaktif)

Isi nomor Anda:

-

Box price: ___

-

Expected trips: ___

-

Cleaning/repair per trip: ___

-

Cost per trip = (price ÷ trips) + cleaning/repair = ___

-

Current damage rate: ___%

-

Cost per damaged shipment: ___

-

Expected damage reduction: ___%

Aturan praktis: If avoided damage cost per month is higher than your packaging cost increase, the switch pays back.

| Skenario | Why a shock resistant EPP foam box helps | When it pays back fastest |

|---|---|---|

| Fragile electronics | fewer DOA returns | high claim cost |

| Cold chain foods | lebih sedikit kebocoran + rejects | frequent re-deliveries |

| Heavy parts | less crush damage | rough handling lanes |

How Do You Choose a Shock Resistant EPP Foam Box Supplier?

Your supplier should help you build repeatable performance, not just a good-looking sample. Ask how they control density consistency, dimensional stability, tutup pas, and insert precision.

Supplier evaluation checklist

| Kemampuan | Apa yang harus ditanyakan | Seperti apa “bagus” itu | Apa artinya bagimu |

|---|---|---|---|

| Material control | density tolerances | consistent batches | predictable protection |

| perkakas | menyisipkan + lid precision | pas, low wobble | lebih sedikit kegagalan |

| Testing support | drop/vibration plans | clear reports | faster approval |

| Scale readiness | stable lead times | repeatable output | fewer supply shocks |

Tip Pembelian Praktis

-

Tes multiple production samples, not one “perfect” prototype.

-

Specify the insert geometry in writing—insert drift changes results.

-

Agree on your evidence pack: Mengemas foto + criteria + Hasil.

2025 Latest Trends in Shock Resistant EPP Foam Box Design

Di dalam 2025, shock resistant EPP foam box programs are moving toward proof-first packaging Dan simpler reuse operations. Teams want fewer packaging SKUs that cover more lanes, plus faster validation.

shock resistant EPP foam box

Latest progress you’ll see more often

-

Modular insert families: one outer box, many payload fits

-

Better lid interfaces: less shifting under vibration

-

Stronger evidence packs: foto + test results + lane assumptions

-

More sensor-backed shipments: terkejut + temperature logs for root-cause clarity

shock resistant EPP foam box

Wawasan pasar (bahasa sederhana)

Reliability wins. When the shock resistant EPP foam box behaves predictably, you spend less time re-shipping and arguing.

Pertanyaan yang sering diajukan

Q1: How do I choose a shock resistant EPP foam box for fragile electronics?

Pick a shock resistant EPP foam box with a precision insert that prevents movement. Validate with repeated corner drops and vibration.

Q2: Does thicker foam always mean better protection?

TIDAK. If it is too soft, it bottoms out. Balanced density plus good corner geometry protects better.

Q3: Can a shock resistant EPP foam box work for cold chain delivery?

Ya, but you still need a consistent coolant layout and a tight lid seal. Packing design controls hold time.

Q4: How do I know if my payload fit is correct?

If it rattles when you gently shake the packed box, the cavity is too loose. Add inserts or adjust the design.

shock resistant EPP foam box

Q5: How do I increase reuse cycles for a shock resistant EPP foam box?

Inspect corners and lids, dry fully after cleaning, and retire worn boxes early to protect performance.

Ringkasan dan Rekomendasi

A shock resistant EPP foam box works best when you treat it as a system: correct density, sisipan yang stabil, tight closure, and repeatable testing. Start with your lane hazards—drops, getaran, menumpuk, and temperature exposure. Then design for corners, lock down fit, and validate “as packed.” If you reuse, add inspection and cycle tracking so performance stays steady over time.

Langkah Anda selanjutnya: pilot one SKU group on one lane, run a repeatable drop/vibration plan, and compare damage and labor to your baseline.

Tentang tempk

Dan Tempk, we design packaging systems that hold up under real logistics pressure. We focus on stable insulation layouts, dependable impact protection, and reuse workflows that stay clean and consistent. If you want a lane-specific recommendation for a shock resistant EPP foam box—size, density direction, insert strategy, and a simple test plan—we can help you build a practical packaging review and proof pack.