Ketika rantai pasokan menjadi semakin kompleks, menjaga integritas suhu memerlukan solusi pendinginan granular. Paket es kering (satuan CO₂ padat) menyediakan kontrol suhu tingkat bedah untuk logistik jarak jauh, uji klinis, dan e-commerce yang mudah rusak ketika sistem massal gagal.

Keunggulan Teknis Unitized Dry Ice

1. Kinerja Kriogenik yang Ditargetkan

-

Mempertahankan suhu -78,5°C pada saat dibutuhkan

-

40% Pengguna termal yang lebih panjang. setara gel

-

Pendinginan presisi untuk:

-

Biologi bernilai tinggi

-

Spesimen diagnostik

-

Barang premium yang mudah rusak

-

2. Sublimasi Tanpa Kontaminasi

-

Perubahan fasa padat→gas dihilangkan:

-

Risiko pencelupan produk

-

Persyaratan pengemasan sekunder

-

Potensi kontaminasi silang

-

3. Optimalisasi Logistik

-

30% pengurangan ruang vs. pendinginan tradisional

-

Mengaktifkan TL campuran (Sepenuh truk) konfigurasi

-

Penanganan yang disederhanakan dengan kenyamanan dosis unit

Implementasi Khusus Sektor

| Vertikal | Aplikasi kritis | Dampak Kepatuhan |

|---|---|---|

| Farmasi | Distribusi uji klinis | 21 Bagian CFR 11 kepatuhan |

| Logistik Makanan | Pemenuhan paket makanan | kepatuhan suhu HACCP |

| Diagnostik | Pemindahan spesimen dari laboratorium ke laboratorium | Integritas sampel CLIA/CAP |

Solusi Paket Rekayasa Tempk

✓ Kinerja Termal yang Divalidasi

-

Perlindungan termal 72 jam yang diverifikasi pihak ketiga

-

Pemeliharaan stabil pada suhu -70°C dalam transit paket

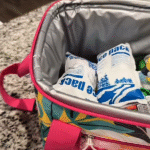

✓ Faktor Bentuk Adaptif

-

Konfigurasi yang disatukan:

-

100-500g paket spesimen medis

-

1-3kg format e-niaga

-

Sistem matriks yang kompatibel dengan palet

-

✓ Desain Siap Regulasi

-

Kemasan berventilasi yang sesuai dengan IATA

-

Opsi pencatatan suhu tertanam

✓ Rantai Dingin Berkelanjutan

-

Manufaktur netral karbon

-

Inisiatif daur ulang loop tertutup

Keuntungan Operasional

Efisiensi Mil Terakhir

-

92% pengurangan perjalanan suhu untuk pengiriman kesehatan di rumah

-

28% pembongkaran/pemrosesan lebih cepat vs. es kering massal

Ketahanan Rantai Pasokan

-

Memungkinkan transisi suhu bertahap (MISALNYA., -70°C → -20°C)

-

Menyederhanakan logistik terbalik untuk kontainer yang dapat digunakan kembali

Mengapa Tempk Memberikan Nilai

Studi kasus: Perusahaan bioteknologi global mengurangi kerugian pengiriman uji klinis sebesar 78% sekaligus memangkas biaya cairan pendingin 32% melalui paket perubahan fase Tempk yang dapat diprogram.

Kesimpulan

Paket es kering mengatasi kesenjangan kritis dalam rantai dingin modern melalui kontrol suhu yang presisi, Operasi bebas kontaminasi, dan penyederhanaan logistik. Solusi rekayasa Tempk memberikan kinerja termal yang tervalidasi, konfigurasi khusus aplikasi, dan keberlanjutan untuk farmasi, diagnostik, dan pengiriman makanan premium. Untuk pemimpin rantai pasokan yang memerlukan jaminan suhu siap audit dalam model distribusi terfragmentasi, Teknologi es kering Tempk memberikan ROI yang terukur melalui pengurangan limbah dan optimalisasi pengoperasian.