Kotak Panel Isolasi Vakum untuk Pengiriman Terkendali Suhu: A 2025 Memandu

Diperbarui 30 November 2025

Di dalam 2025 industri pengemasan rantai dingin terus berkembang pesat. Analis memperkirakan bahwa pasar kemasan rantai dingin tumbuh sekitar USD 29.35 miliar masuk 2024 dan diproyeksikan melebihi USD 55.68 miliar oleh 2035. Di luar kemasan, itu pasar logistik rantai dingin global bernilai sekitar USD 436 miliar masuk 2025 dan bisa mendekati USD 1.36 triliun sebesar 2034. Lonjakan ini didorong oleh permintaan e-commerce terhadap makanan segar, distribusi vaksin yang terus meningkat dan peraturan yang ketat. Dalam konteks ini, itu kotak panel isolasi vakum untuk pengiriman dengan suhu terkontrol—wadah ringan dengan insulasi ultra tipis—telah menjadi alat standar terbaik untuk melindungi barang-barang yang sensitif terhadap suhu. Panduan ini menjelaskan apa saja kotak-kotak itu, mengapa hal ini penting dan bagaimana Anda dapat memanfaatkannya untuk menjaga keamanan produk.

Apa yang membuat kotak panel isolasi vakum istimewa untuk pengiriman rantai dingin? Pahami desain dan ilmu pengetahuan di balik panel insulasi vakum dan bagaimana kinerjanya mengungguli material tradisional.

Mengapa Anda harus memilih kotak panel isolasi vakum untuk produk yang sensitif terhadap suhu? Pelajari keuntungannya—termasuk kontrol suhu yang lebih lama, dinding lebih tipis dan bobot lebih rendah.

Batasan apa yang harus Anda ketahui? Temukan biayanya, kerapuhan dan pertimbangan lingkungan dari kemasan berinsulasi vakum.

Bagaimana Anda bisa memilih kotak yang tepat? Dapatkan panduan langkah demi langkah tentang pencocokan kinerja kotak dengan produk Anda, durasi transit dan kebutuhan kepatuhan.

Tren apa yang akan membentuk kotak panel isolasi vakum 2025? Jelajahi inovasi seperti pendingin hybrid, Kotak berkemampuan IoT dan material ramah lingkungan.

Apa Itu Kotak Panel Isolasi Vakum dan Bagaimana Cara Kerjanya?

Bagaimana teknologi itu bekerja

Panel isolasi vakum (VIP) kotak adalah wadah kaku yang menggunakan inti yang dievakuasi untuk memperlambat perpindahan panas secara drastis, mempertahankan suhu stabil selama berhari-hari. Setiap panel berisi inti berpori—biasanya silika berasap—yang disegel dalam film penghalang kedap udara dan dievakuasi hingga mendekati ruang hampa.. Karena gas menghantarkan panas, menghilangkan udara hanya menyisakan matriks padat untuk mengirimkan energi. Itu konduktivitas termal VIP adalah tentang 5 mW/m·K, menjadikannya jauh lebih efisien daripada polistiren yang diperluas (EPS) atau busa poliuretan. Pabrikan biasanya mengapit beberapa panel untuk membentuk dinding kotak; rongga menampung muatan dan bahan perubahan fasa (PCMS) seperti paket gel atau es kering. Saat digunakan dengan PCM, Kotak VIP bisa pertahankan suhu yang dibutuhkan selama 7–10 hari—dua hingga tiga kali lebih lama dibandingkan isolasi konvensional.

Komponen utama

Inti VIP: Terbuat dari silika mikropori atau serat kaca. Inti yang dievakuasi memberikan konduktivitas termal yang rendah.

Film penghalang: Laminasi multi lapis yang terbuat dari aluminium foil dan lapisan polimer mencegah masuknya gas. Permukaan reflektif juga membatasi perpindahan panas radiasi.

Struktur pendukung: Ruang hampa menarik panel ke dalam; untuk mencegah keruntuhan, pabrikan memasukkan spacer atau menggunakan inti yang diperkuat aerogel.

Kulit luar: Kasus yang kaku (sering kali plastik bergelombang atau papan serat) melindungi panel VIP dari tusukan dan kelembapan.

Bahan perubahan fasa: Paket gel, es kering atau PCM menyerap dan melepaskan panas laten untuk mengontrol suhu internal.

Kombinasi ini menciptakan a ringan, kotak berkinerja tinggi ideal untuk pengiriman vaksin, Biologi, makanan segar dan bahan kimia khusus.

Mengapa panel isolasi vakum adalah pengubah permainan

Para peneliti dan pakar pengemasan menganggap teknologi VIP sebagai sebuah terobosan. Laporan ColdChainPacking mencatat hal itu VIP menggunakan inti yang disegel vakum untuk meminimalkan perpindahan panas; konduktivitas yang berkurang memungkinkan lapisan insulasi menjadi lebih tipis, ukuran kemasan lebih kecil dan bobot lebih ringan. Keuntungan ini sangat penting untuk pengiriman ekspres atau kargo udara dimana ruang dan berat mempengaruhi biaya. Analisis Sofrigam menyoroti hal itu Kotak VIP mempertahankan kisaran suhu yang diperlukan selama 7–10 hari, yang dua hingga tiga kali lebih lama dari isolasi konvensional terbaik. Karena dindingnya lebih tipis, Anda dapat meningkatkan volume yang dapat digunakan atau mengurangi berat cairan pendingin.

Pertanyaan umum tentang VIP

| Pertanyaan | Menjawab |

| Berapa suhu yang dapat ditampung oleh kotak VIP? | Tergantung pada PCMnya, Kotak VIP dapat dipertahankan 2–8 °C untuk obat-obatan, -18 °C untuk makanan beku atau bahkan kondisi sangat dingin dengan es kering. |

| Berapa lama kotak VIP bertahan? | Kemasan VIP standar menjaga suhu selama 7–10 hari. Desain hybrid yang menggunakan PCM yang lebih tipis dapat bertahan suhu yang tepat untuk 72 jam atau lebih lama. |

| Apakah kotak VIP dapat digunakan kembali? | Banyak kontainer VIP dapat digunakan kembali; penggunaan kembali tergantung pada selubung pelindung dan protokol pembersihan. Analis pasar memperkirakan kemasan rantai dingin yang dapat digunakan kembali akan tumbuh dari USD 4.97 miliar masuk 2025 ke USD 9.13 miliar oleh 2034, dengan kontainer VIP membentuk segmen utama. |

| Apakah mereka berkelanjutan?? | VIP menawarkan penghematan energi namun memiliki dampak lingkungan produksi silika pirogenik. A 2019 studi mencatat bahwa VIP memilikinya potensi rumah kaca yang tinggi, namun mendaur ulang inti silika dapat mengurangi biaya ekologis 95 %. Proyek seperti inisiatif ekonomi sirkular Peli BioThermal bertujuan untuk menggunakan kembali inti VIP dan mengurangi emisi karbon. |

Wawasan praktis: perhitungan sampel

Bayangkan pengiriman vaksin sebanyak 5 liter yang membutuhkan suhu 2–8 °C selama lima hari. Menggunakan a 20 mm Pendingin EPS membutuhkan sekitar 4 kg bungkus gel dan daunnya saja 6 liter volume internal. Kotak VIP dengan ukuran eksternal yang sama digunakan 10 panel mm dan kebutuhan saja 1.5 kg PCM. Anda mendapatkan volume ekstra, mengurangi berat pengiriman dan memperpanjang waktu tunggu.

Kasus dunia nyata

Kasus aktual: Sebuah perusahaan farmasi yang mengirimkan produk biologi menggunakan a kotak pintar yang dapat digunakan kembali dengan panel VIP dan PCM itu mempertahankan 2–8 °C selama 72 jam saat mentransmisikan data suhu dan lokasi langsung. Jika tutupnya terbuka atau suhunya turun, peringatan otomatis memicu tindakan perbaikan, melestarikan kargo bernilai tinggi.

Mengapa Memilih Kotak Panel Isolasi Vakum untuk Pengiriman Terkendali Suhu?

Keunggulan dibandingkan isolasi konvensional

Keuntungan utama kotak panel insulasi vakum adalah kinerja termal yang unggul dengan ketebalan material yang lebih rendah, diterjemahkan menjadi waktu tunggu yang lebih lama dan pengiriman yang lebih ringan. Sofrigam mencatat itu VIP menawarkan konduktivitas termal sekitar 5 mW/m·K, jauh di bawah bahan seperti EPS atau busa poliuretan. Hal ini memungkinkan ketebalan dinding menjadi berkurang sambil tetap mencapai pemeliharaan suhu 7–10 hari. Karena dindingnya lebih tipis, Anda mendapatkan lebih banyak ruang internal atau dapat mengurangi jumlah cairan pendingin. ColdChainPacking menekankan hal itu VIP mengungguli material tradisional dengan memungkinkan lapisan isolasi yang lebih tipis dan mengurangi ukuran dan berat kemasan secara keseluruhan, yang sangat bermanfaat ketika ruang terbatas atau pengurangan berat badan merupakan prioritas.

Keunggulan lainnya antara lain:

Durasi diperpanjang: Kotak VIP mempertahankan rentang suhu jauh lebih lama dibandingkan pendingin busa standar. Hal ini memungkinkan pengiriman melalui rute yang lebih panjang atau waktu tunggu yang lebih lama selama pengurusan bea cukai.

Efisiensi ruang: Dinding yang lebih tipis membebaskan volume internal, memungkinkan Anda mengirimkan lebih banyak produk per kontainer atau menggunakan kontainer yang lebih kecil untuk muatan yang sama.

Pengurangan berat badan: Ketebalan isolasi yang lebih rendah dan kemampuan untuk mengurangi massa PCM berarti berat total lebih sedikit. Hal ini secara langsung menurunkan biaya pengiriman barang melalui udara.

Konsistensi: VIP membuat profil suhu lebih stabil dengan fluktuasi minimal. ColdChainPacking mencatat penggabungan itu VIP dengan material pengubah fasa memberikan solusi ampuh untuk mempertahankan suhu yang konsisten selama periode transportasi yang lama.

Perlindungan bernilai tinggi: Banyak vaksin yang menyelamatkan nyawa, makanan biologis dan khusus memerlukan rentang suhu yang ketat. Kotak VIP memberikan keandalan yang dibutuhkan untuk pengiriman bernilai tinggi.

Kekurangan dan keterbatasan

Terlepas dari manfaatnya, Kotak VIP juga memiliki tantangan:

Kerapuhan: Sofrigam menunjukkan bahwa panel VIP rapuh dan biasanya membutuhkan bahan lain (seperti busa PU) untuk perlindungan, yang meningkatkan ketebalan total.

Biaya: Meski biayanya semakin berkurang, VIP tetap ada lebih mahal daripada isolasi tradisional.

Batasan bentuk: Panel tidak berbentuk persegi sempurna atau mudah dipotong, mempersulit perakitan kotak dan menciptakan jembatan termal potensial.

Berat: Inti VIP memiliki a kepadatan 150–250 kg/m³, membuatnya lebih berat daripada beberapa busa.

Dampak Lingkungan: Memproduksi silika pirogenik memerlukan energi yang signifikan dan menghasilkan kandungan karbon yang tinggi. Daur ulang dapat mengurangi hal ini.

Ringkasan komparatif

| Bahan isolasi | Konduktivitas termal (kira-kira.) | Ketebalan dinding untuk 72 h tahan | Biaya & kompleksitas | Signifikansi praktis |

| Polystyrene yang diperluas (EPS) | ~36 mW/m·K (8 kali lebih tinggi dari VIP) | 30–40mm | Biaya rendah; mudah dipotong | Terjangkau tetapi berat dan besar; waktu penahanan dibatasi hingga ~2–3 hari. |

| Busa Poliuretan (Pur) | ~22 mW/m·K | 25–35 mm | Biaya sedang; kekakuan sedang | Isolasi lebih baik dari EPS tetapi masih lebih tebal dan lebih berat dari VIP; waktu tunggu ~3–5 hari. |

| Panel Insulasi Vakum (VIP) | ≈5mW/m·K | 10–15 mm (50–70 % lebih tipis) | Biaya tinggi; rentan | Waktu tunggu yang diperpanjang 7–10 hari; lebih banyak ruang internal; penghematan berat badan. |

(Catatan: nilai perkiraan; kinerja sebenarnya tergantung pada kualitas panel dan desain kemasan.)

Tip dan rekomendasi praktis

Prioritaskan jenis muatan: Gunakan kotak VIP untuk barang bernilai tinggi atau sensitif (MISALNYA., vaksin, Biologi, makanan khusus) dimana biayanya dapat dibenarkan.

Kombinasikan dengan PCM: Pilih PCM yang sesuai dengan kisaran suhu Anda (2–8 ° C., –20 °C atau –70 °C). Memasangkan VIP dengan PCM yang sesuai memastikan kondisi internal yang stabil.

Lindungi dari tusukan: Selalu gunakan kulit terluar (EPP, plastik bergelombang atau papan serat) untuk melindungi panel dari kerusakan.

Rencanakan logistik pengembalian: Jika menggunakan kotak VIP yang dapat digunakan kembali, mengoordinasikan logistik terbalik untuk memulihkan kotak dan menjaga keberlanjutan.

Kasus dunia nyata

Kasus aktual: ColdChainPacking mencatat penggabungan itu panel isolasi vakum dengan bahan pengubah fasa menawarkan solusi yang ampuh. VIP mengurangi perpindahan panas dan PCM menyerap dan melepaskan energi panas, menjaga suhu lingkungan yang stabil selama transportasi panjang.

Cara Memilih Kotak Panel Isolasi Vakum yang Tepat untuk Kiriman Anda

Memilih kontainer VIP yang tepat adalah tentang menyeimbangkan kebutuhan produk, kondisi transit, persyaratan peraturan dan biaya. Gunakan kerangka kerja berikut untuk membuat keputusan Anda.

Evaluasi profil termal produk Anda

Identifikasi kisaran suhu yang diperlukan. Farmasi seringkali membutuhkan 2–8 ° C., kebutuhan makanan beku –18 °C dan bahan biologis ultra dingin mungkin diperlukan –70 °C. Tentukan berapa lama produk harus tetap berada dalam kisaran ini (jam vs hari). Sofrigam melaporkan bahwa kotak VIP menjaga jangkauan 7–10 hari; desain hybrid tetap dipertahankan 72 + jam dengan PCM yang lebih tipis.

Perkirakan durasi transit dan lingkungan

Pertimbangkan jarak pengiriman, potensi penundaan dan suhu eksternal. Kotak VIP pasif cocok untuk durasi sedang (hingga satu minggu). Untuk rute yang lebih panjang atau kondisi ekstrim, mempertimbangkan kemasan hybrid atau aktif (MISALNYA., dibangun dalam pendingin).

Cocokkan PCM dan jenis cairan pendingin

Pilih PCM atau kemasan gel dengan titik leleh yang selaras dengan rentang suhu produk Anda. Panduan CNNBOX menekankan hal itu PCM seperti paket gel, kantong es dan es kering memainkan peran penting; mereka menyerap dan melepaskan energi panas untuk mempertahankan suhu yang diinginkan. Gunakan beberapa paket PCM untuk penyimpanan lebih lama.

Tentukan ukuran kotak dan rasio muatan

Dinding VIP yang lebih tipis menambah ruang yang dapat digunakan. Hitung volume internal yang dibutuhkan untuk produk dan cairan pendingin. Hindari ukuran yang terlalu besar; udara ekstra di dalam kotak meningkatkan beban termal.

Menilai persyaratan peraturan dan kepatuhan

Mematuhi standar internasional seperti Pedoman WHO untuk penyimpanan vaksin Dan Undang-Undang Modernisasi Keamanan Pangan FDA. Untuk obat -obatan, Praktek Distribusi yang Baik (PDB) dan Praktek Manufaktur yang Baik (GMP) standar mengamanatkan pengemasan yang divalidasi dan pemantauan waktu nyata.

Seimbangkan biaya vs kinerja

Kotak VIP lebih mahal di muka tetapi dapat mengurangi kerugian akibat pembusukan dan dapat menurunkan biaya pengiriman karena penghematan berat. Pertimbangkan total biaya kepemilikan, termasuk siklus penggunaan kembali dan logistik terbalik.

Pertimbangkan keberlanjutan

Pilihlah desain dengan panel yang dapat didaur ulang, casing luar yang dapat digunakan kembali atau insulasi berbahan dasar tanaman. Pendingin hybrid baru menggabungkan VIP dengan PCM yang lebih tipis untuk menjaga suhu 72 + jam sekaligus mengurangi penggunaan bahan bakar. Proyek seperti inisiatif ekonomi sirkular Peli BioThermal menunjukkan hal tersebut mendaur ulang inti VIP dapat mengurangi dampak ekologis dengan 95 %.

Daftar periksa penilaian diri

Gunakan tes mandiri cepat ini untuk menentukan solusi mana yang cocok untuk Anda:

Berapa kisaran suhu yang dibutuhkan produk saya? – 2–8 °C, –18 °C atau –70 °C.

Berapa lama kiriman saya akan transit? - - <48 H (pertimbangkan VIP standar), 48–72 jam (VIP hibrida), >72 H (kemasan hybrid atau aktif).

Betapa berharganya produk tersebut? – Rendah hingga sedang (gunakan EPS atau PUR yang hemat biaya), Tinggi (berinvestasi dalam solusi VIP atau hybrid).

Apakah saya memiliki logistik terbalik untuk dapat digunakan kembali? - Ya (pilih kotak VIP yang dapat digunakan kembali), TIDAK (pilih sekali pakai tetapi rencanakan pembuangan atau daur ulang).

Peraturan apa yang berlaku? - Makanan (FSMA), Farmasi (SIAPA, GMP/PDB).

Inovasi dan Tren Terbaru Kotak Panel Isolasi Vakum (2025)

Industri rantai dingin berkembang pesat. Riset dan analisis pasar menyoroti beberapa inovasi yang membentuk kemasan VIP.

Pendingin hibrida dengan PCM yang lebih tipis

CNNBOX melaporkan hal itu pendingin hibrida yang menggabungkan isolasi vakum dengan bahan pengubah fasa yang lebih tipis dapat mempertahankan suhu yang tepat lebih dari 72 jam sekaligus mengurangi penggunaan bahan bakar. Desain ini meminimalkan konsumsi energi dengan memanfaatkan efisiensi insulasi tinggi dan mengoptimalkan massa PCM.

Pengemasan cerdas yang mendukung IoT

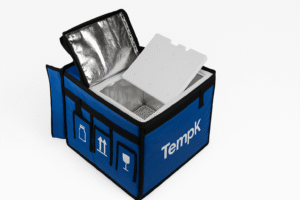

Kemasan cerdas mengintegrasikan sensor, pencatat data dan konektivitas. Artikel pengetahuan Tempk mencatat hal itu wadah yang dapat digunakan kembali dengan sensor, panel berinsulasi vakum dan material pengubah fasa dapat mempertahankan suhu presisi selama 48–72 jam saat mentransmisikan data langsung, mengurangi ketergantungan pada es kering dan kemasan gel. Pengirim cerdas ini mengirimkan peringatan waktu nyata ketika suhu menyimpang, memungkinkan tindakan perbaikan yang cepat.

Wadah multi zona suhu

Kontainer canggih membagi interior menjadi beberapa kompartemen dengan zona suhu berbeda, memungkinkan beban campuran (MISALNYA., ikan beku dan sayuran segar). Tempk menyoroti apa yang diandalkan oleh pengirim multi-zona ini panel isolasi vakum dan pemantauan cerdas untuk mengelola beragam kebutuhan termal secara bersamaan.

Model kemasan yang dapat digunakan kembali dan melingkar

Analis memperkirakan pertumbuhan yang kuat untuk kemasan rantai dingin yang dapat digunakan kembali: pasar diproyeksikan akan berkembang USD 4.97 miliar masuk 2025 ke USD 9.13 miliar oleh 2034. Kontainer VIP yang dapat digunakan kembali mengurangi limbah dan menawarkan manfaat biaya jangka panjang. Sistem loop tertutup seperti pengumpulan RPC menekankan pengembalian, pembersihan dan pendistribusian kembali kontainer. Perusahaan sedang bereksperimen PCM dan pelapis busa bio yang dapat terurai secara hayati dan nabati untuk mengurangi jejak karbon.

Kotak pintar yang didinginkan sendiri

Produk-produk yang sedang berkembang seperti bertenaga baterai, wadah berpendingin sendiri (MISALNYA., Kubus Bara) menghilangkan kebutuhan akan paket gel atau es kering. Kotak-kotak ini terawat 2–8 °C selama 48–72 jam, termasuk isolasi dan sensor VIP, dan mengirimkan data untuk pelacakan.

Integrasi AI dan blockchain

Kecerdasan buatan menganalisis data sensor untuk memprediksi kegagalan peralatan, mengoptimalkan rute dan mengurangi penundaan. Blockchain menyediakan log bukti kerusakan data suhu dan kejadian penanganan, meningkatkan kepatuhan dan kemampuan audit.

Pertumbuhan dan segmentasi pasar

Studi pasar menunjukkan bahwa kontainer VIP akan mengambil pangsa lebih besar di segmen pengemasan rantai dingin. Wadah yang dapat digunakan kembali (termasuk pengirim VIP) mendominasi pangsa jenis produk 2024 dan akan terus berkembang. Amerika Utara memimpin adopsi, namun Asia Pasifik menunjukkan potensi pertumbuhan yang signifikan.

Ringkasan tren

Bahan berkelanjutan: Isolasi berbasis bio, plastik daur ulang dan PCM yang dapat terbiodegradasi.

Sensor pintar: Suhu waktu nyata, pemantauan lokasi dan dampak.

Desain modular: Kombinasi PCM dan isolasi yang telah diuji sebelumnya untuk penyesuaian cepat.

Tekanan regulasi: Pedoman yang lebih ketat memerlukan proses yang tervalidasi, pemantauan dan dokumentasi.

Ekonomi melingkar: Mendaur ulang inti VIP dan menggunakan sistem yang dapat digunakan kembali untuk mengurangi emisi karbon.

Pertanyaan yang sering diajukan

Q1: Apa itu kotak panel isolasi vakum?

Kotak VIP adalah kontainer pengiriman yang dindingnya terbuat dari panel tipis bersegel vakum yang terbuat dari silika mikropori. Menghilangkan udara secara drastis menurunkan konduktivitas termal, membiarkan kotak mempertahankan suhu selama beberapa hari.

Q2: Berapa lama kotak panel isolasi vakum dapat menjaga barang tetap dingin?

Kotak VIP standar menjaga suhu 7–10 hari. Desain hibrid dengan PCM yang lebih tipis atau pendinginan aktif menjaga suhu tetap presisi 72 + jam.

Q3: Apakah kotak panel isolasi vakum dapat digunakan kembali?

Banyak kotak VIP dirancang untuk digunakan kembali. Pasar kemasan rantai dingin yang dapat digunakan kembali diproyeksikan akan tumbuh USD 4.97 miliar masuk 2025 ke USD 9.13 miliar oleh 2034, mencerminkan pergeseran ke arah penggunaan kembali.

Q4: Apa kelemahan utamanya?

Panel VIP rapuh, mahal dan lebih berat dari beberapa busa. Bahan-bahan tersebut juga memerlukan penanganan yang hati-hati dan pembuangan atau daur ulang yang benar untuk mengurangi dampak lingkungan.

Q5: Bagaimana cara memilih antara kemasan VIP pasif dan hybrid?

Pertimbangkan durasi, nilai produk dan persyaratan peraturan. Kotak VIP pasif berfungsi untuk pengiriman hingga satu minggu; kotak hybrid atau aktif lebih baik untuk rute yang lebih panjang atau barang bernilai tinggi yang memerlukan pemantauan waktu nyata.

Ringkasan dan Rekomendasi

Di era booming logistik rantai dingin, kotak panel isolasi vakum menawarkan kinerja termal yang tak tertandingi, menjaga obat-obatan, biologis dan makanan segar dalam kisaran suhu yang ketat selama berhari-hari. Milik mereka konduktivitas termal yang rendah (~5 mW/m·K) Dan dinding tipis mengantarkan 7–10 hari waktu tunggu, sekaligus mengurangi berat dan meningkatkan volume muatan. Namun, biaya, kerapuhan dan jejak lingkungan harus ditimbang. Untuk memilih solusi yang tepat, tentukan kisaran suhu Anda, memperkirakan durasi transit, cocok dengan PCM, pertimbangkan regulasi, biaya keseimbangan Dan keberlanjutan faktor. Kemasan hibrida dan cerdas mengubah lanskap, menawarkan durasi yang lebih lama, data langsung dan materi berkelanjutan. Mengadopsi inovasi ini membantu mengurangi limbah dan mematuhi peraturan yang lebih ketat, melindungi produk dan planet ini.

Langkah selanjutnya yang dapat ditindaklanjuti

Audit kebutuhan rantai dingin Anda: Petakan jenis produk, suhu dan durasi transit yang diperlukan.

Evaluasi opsi VIP: Bandingkan kotak yang tersedia berdasarkan ketebalan insulasi, Tipe PCM, tahan waktu dan biaya.

Melaksanakan pemantauan: Lengkapi pengiriman dengan sensor suhu dan pertimbangkan kotak pintar untuk barang bernilai tinggi.

Rencanakan untuk digunakan kembali: Pilih kontainer VIP yang dapat digunakan kembali di mana logistik terbalik dapat dilakukan dan dukung inisiatif daur ulang.

Konsultasikan dengan para ahli: Bekerja samalah dengan spesialis rantai dingin untuk menyesuaikan kemasan dan memastikan kepatuhan terhadap peraturan.

Tentang tempk

Didirikan pada 2011, Tempk (Shanghai Huizhou Industri Co., Ltd.) adalah perusahaan teknologi tinggi yang mengkhususkan diri dalam penelitian, pengembangan dan produksi produk kemasan rantai dingin. Berbasis di Shanghai dengan lebih dari tujuh pabrik di seluruh China, yang disediakan perusahaan bahan penyimpanan dingin perubahan fasa, kemasan termal untuk transportasi, peralatan pendingin farmasi, produk isolasi makanan segar dan layanan verifikasi kontrol suhu. Tempk menyediakan paket es gel, Paket es kering, kotak terisolasi, Kulkas medis VIP, pelapis kotak dan penutup palet berinsulasi untuk grup farmasi besar dan perusahaan e-commerce makanan segar. Dengan komitmen terhadap inovasi dan kualitas, Tempk mendukung pelanggan dengan 24/7 layanan daring, pelacakan waktu nyata Dan solusi ramah lingkungan.

Panggilan untuk bertindak

Jika Anda perlu menjaga barang yang sensitif terhadap suhu, terhubung dengan Tempk. Pakar mereka dapat membantu Anda memilih atau menyesuaikan kotak panel insulasi vakum untuk pengiriman dengan suhu terkontrol, mengevaluasi strategi rantai dingin Anda dan memberikan solusi terintegrasi.