Dernière mise à jour: Janvier 28, 2026

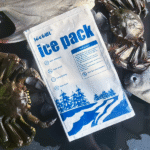

A gel cooling pad chocolate manufacturer can decide whether your chocolate arrives glossy or arrives as a refund. Chocolate reacts quickly to heat spikes and temperature swings, especially during sorting and last-mile delays. Your goal is not “very cold.” Your goal is stable and moderate cooling that protects texture, apparence, and customer trust. Ce 2026 guide shows you how to choose the right manufacturer, validate performance, and standardize pack-out.

Cet article répondra pour vous

How a gel cooling pad chocolate manufacturer protects chocolate quality in real shipping conditions

Which gel pad formats work best for bars, truffles, and assortments

How to evaluate thermal data without engineering overload

A repeatable pack-out SOP you can train in one day

How to lower total cost per shipment without raising melt risk

2026 tendances: validation language, durability upgrades, et durabilité

How Does a Gel Cooling Pad Chocolate Manufacturer Protect Chocolate Quality?

Réponse directe: A gel cooling pad chocolate manufacturer protects chocolate by buffering heat spikes and keeping the inside of your shipper stable during handling delays. The best pads absorb incoming heat gradually and release cooling evenly. That reduces softening, bloom risk, and messy packaging outcomes.

Explication élargie: Chocolate shipping is not a freezer problem. It is a stability problem. When a parcel warms up in a depot, then cools again, the product can lose its clean finish and “snap.” A strong manufacturer designs pads to avoid sharp temperature swings and avoid overcooling that can cause condensation. Think of gel cooling like cruise control in traffic. It stops sudden surges.

Quoi “Refroidissement modéré” Means for Chocolate in Plain Language

Moderate cooling means you aim for a range that keeps chocolate firm and stable, without making the box “sweat.” If you go too cold, moisture can condense when the box is opened. That can create a dusty look and reduce shelf appeal.

| Chocolate Issue | Common Trigger | What Gel Pads Should Do | Signification pratique pour vous |

|---|---|---|---|

| Soft arrival | Short heat spike | Slow heat absorption | Fewer replacement shipments |

| Bloom complaints | Repeated warm/cool cycles | Reduce swings | Better unboxing photos |

| Damp packaging | Refroidissement excessif + humidité | Avoid cold dips | Cleaner premium presentation |

Conseils pratiques que vous pouvez utiliser aujourd'hui

If your lane is unpredictable: Ask your gel cooling pad chocolate manufacturer for a “delay cushion” conception.

If unboxing matters: Add a moisture barrier layer to keep things dry and neat.

If you ship assortments: Design for your most sensitive piece, often filled items.

Cas pratique: A gift brand reduced “arrived soft” complaints after switching to a validated gel pad system with top-and-side coverage.

What Should a Gel Cooling Pad Chocolate Manufacturer Actually Build for You?

Réponse directe: A gel cooling pad chocolate manufacturer should build a system-ready cooling component, not just a generic pack. That includes the right gel mass, durable film, reliable seals, and a pad shape that fits your box footprint.

Explication élargie: Many failures happen because the pad is not the right shape for the shipper. A pad that slides creates hot spots. A pad that is too stiff creates poor contact. A pad that leaks ruins your labels and inserts. Dans 2026, you should expect the manufacturer to support your process with consistent sizing and clear QA controls.

Core Design Levers (Simple and Useful)

| Design Lever | What It Changes | Common Options | Your Trade-Off |

|---|---|---|---|

| Gel mass | Durée de refroidissement | Lumière / Moyen / Lourd | Duration vs. poids |

| Film strength | Leak resistance | Standard / Renforcé | Durability vs. coût |

| Seal pattern | Burst protection | Edge / Multi-seal | Reliability vs. complexité |

| Pad shape | Contact + couverture | Panel / Envelopper / Lid pad | Fit vs. flexibilité |

Buyer-Friendly Advice

Ask for recommended pad placement, not only pad specs.

Choose reinforced film if parcels face rough sorting.

Standardize sizes to reduce packing mistakes and training time.

Cas pratique: A D2C chocolatier improved on-time quality by standardizing one pad size and one photo SOP.

Which Gel Pad Formats Should Your Gel Cooling Pad Chocolate Manufacturer Offer?

Réponse directe: A good gel cooling pad chocolate manufacturer should offer panels, wrap-style pads, top-lid pads, and custom footprints. Chocolate needs even cooling coverage and stable placement.

Explication élargie: Format is not decoration. It is performance. A panel provides broad coverage. A wrap improves contact around inner cartons. A top-lid pad protects against porch heat, where heat often enters from above. If your manufacturer only offers one format, you may end up compensating with extra pads and higher cost.

Format Selection Mini-Guide

| Format | Mieux pour | Erreur courante | Better Practice |

|---|---|---|---|

| Flat panel | Bars, plateaux, cartons | Floating in void space | Stabilize with fillers |

| Wrap-style | Assortments, inner cartons | Direct contact on product | Utilisez une couche de barrière |

| Top-lid pad | Exposition au seuil de la porte | Cooling only from bottom | Protect top heat entry |

| Side panels | Routes plus longues | Uneven coverage | Build a “cooling frame” |

Quick Scenario Recommendations

Same-city delivery: One panel + top buffer is often enough.

Two-day shipping: Side panels + top pad improve stability.

Two-to-three day shipping: Full surround + stronger insulation adds a delay cushion.

Cas pratique: A subscription brand reduced summer failures after shifting from “bottom only” cooling to “haut + sides.”

How Do You Vet a Gel Cooling Pad Chocolate Manufacturer Using Thermal Test Data?

Réponse directe: You vet a gel cooling pad chocolate manufacturer by confirming they can show time-at-temperature performance inside your actual shipper, under lane-like conditions. You want curves, repeatability, and a recommended configuration.

Explication élargie: “Gel weight” is not performance. “Freezer time” is not performance. Performance is what the chocolate experiences inside the box over time. Dans 2026, manufacturers who support recognized thermal test approaches and repeatable pilot shipments are safer partners than those who only provide brochures.

The Thermal Curve Reading Shortcut (No Engineering Needed)

Check these three things:

Couverture: Does the safe window cover your promised delivery time plus delays?

Stabilité: Are there sharp spikes or dips inside the box?

Répétabilité: Do multiple tests show similar results?

| What You See | What It Suggests | What to Change | Outcome for You |

|---|---|---|---|

| Fast warm-up | Not enough buffering | Add side panels or upgrade insulation | Protection plus longue |

| Big swings | Poor placement or voids | Stabilize pad contact | Fewer bloom events |

| Cold dip early | Overcooling risk | Adjust pre-conditioning | Moins de condensation |

Outil interactif: Lane Risk Score (2 Minutes)

Donnez-vous des points:

+3 if delivery is over 48 heures

+3 if summer ambient can exceed 30°C

+2 if delivery is unattended

+2 if parcels face multiple handoffs

+1 if you ship filled chocolates

Interprétation des partitions:

0–3: Light system usually works

4–7: Medium system + validation recommended

8–11: High-risk lane—require test curves + pilot proof

Cas pratique: A brand reduced seasonal panic by validating only high-risk lanes first.

What QA and Food-Safety Proof Should a Gel Cooling Pad Chocolate Manufacturer Provide?

Réponse directe: A qualified gel cooling pad chocolate manufacturer should provide seal integrity controls, traçabilité, storage guidance, and material safety documentation. For chocolate, leaks are not minor. They destroy presentation and trigger customer complaints.

Explication élargie: Even if gel is food-safe, a leak during transit can ruin your packaging and your brand image. Dans 2026, expect your manufacturer to show how they prevent and detect seal failures, and how they handle complaints when they occur.

QA Checklist for Chocolate Shippers

| QA Area | Que demander | Pourquoi ça compte | Risk If Missing |

|---|---|---|---|

| Seal testing | Burst and leak checks | Prevents in-box failures | Ruined packaging |

| Lot traceability | Batch codes on packs | Supports recall or audit | Compliance gaps |

| Storage guidance | Temp and humidity limits | Keeps pads ready to use | Weak performance |

| Non-conformance handling | Clear escalation process | Faster resolution | Repeated issues |

Conseil pratique

Ask for a sample batch before committing to a large order. Inspect seals, measure weight consistency, and test one pack-out under real conditions.

How Do You Build a Repeatable Pack-Out SOP for Chocolate?

Réponse directe: You build a repeatable pack-out SOP by defining pad placement, temps de préconditionnement, and a visual checklist. A good gel cooling pad chocolate manufacturer should help you design this process, not just sell you pads.

Explication élargie: Most pack-out failures are process failures, not product failures. When different packers do it differently, results vary. A simple SOP with photos and a weight check can cut errors and reduce seasonal panic.

Pack-Out SOP Template (One-Page Version)

| Étape | Action | Vérifier | Common Error |

|---|---|---|---|

| 1 | Confirm pad pre-conditioning | Time and temp logged | Skipping freezer time |

| 2 | Place bottom insulation | Plat, pas de lacunes | Folded corners |

| 3 | Position gel pad(s) | Contact with product zone | Floating pad |

| 4 | Add barrier layer | Covers gel surface | Direct gel-to-product contact |

| 5 | Charger | Centered, écurie | Off-center placement |

| 6 | Add top pad and close | Snug fit, no voids | Loose top layer |

| 7 | Weigh completed box | Within target range | Missing components |

Training Tip

Post a photo of a correctly packed box at each station. Train once, then audit weekly.

How Do You Lower Total Cost Per Shipment Without Raising Melt Risk?

Réponse directe: You lower total cost per shipment by right-sizing your cooling system, Réduire les déchets, and standardizing your process. A good gel cooling pad chocolate manufacturer helps you avoid over-engineering and under-performing.

Explication élargie: Cost is not just pad price. Cela comprend la main d'œuvre, errors, remplaçants, and customer complaints. Dans 2026, the best savings come from process consistency and lane-matched design, not from buying the cheapest pad.

Cost Optimization Levers

| Levier | Ce qu'il fait | Effort Level | Résultat |

|---|---|---|---|

| Lane-matched design | Avoids over-cooling | Moyen | Lower pad cost per box |

| Standardized SKUs | Reduces inventory | Faible | Moins de déchets + moins d'erreurs |

| Programmes de réutilisation | Return and re-use | Moyen | Lower lifetime cost |

| Fit optimization | Less void space | Moyen | Meilleure stabilité de la température |

| Better training | Fewer repacks | Faible | Less wasted material |

Actions pratiques

Standardize one pad footprint across multiple cartons when possible.

Reserve reusable pads for wholesale or closed-loop routes.

Reduce void space to reduce hot spots and waste.

Cas pratique: A seasonal brand improved unboxing reviews after cutting filler and standardizing pad placement.

2026 Latest Developments in Gel Cooling Pad Chocolate Manufacturer Solutions

Aperçu de la tendance: En janvier 2026, the shift is toward system-level optimization. Brands want fewer variables, moins de SKU, and more predictable outcomes. A strong gel cooling pad chocolate manufacturer is expected to provide pack-out blueprints, not just products.

Dernier aperçu des progrès

Modular panel systems: meilleur ajustement, moins de lacunes, fewer hot corners

Durability upgrades: films and seals built for tougher parcel handling

Ready-to-run kits: pre-defined sets for common transit windows

Lane-based playbooks: warm-season and mild-season SOPs that scale

Perspicacité du marché: The fastest way to improve quality is not adding more gel. It is standardizing the process. When you validate one warm-season system and train it well, you reduce failures across the year.

Questions fréquemment posées

Q1: How do I choose the best gel cooling pad chocolate manufacturer for summer shipping?

Choose one that provides lane-matched thermal proof, reinforced sealing options, and a repeatable warm-season pack-out SOP.

Q2: Can gel cooling pads cause condensation inside the box?

Oui, if overcooled or poorly packed. Use moderated pre-conditioning, couches barrières, and even coverage.

Q3: How many gel pads do I need for chocolate delivery?

It depends on duration, isolation, and heat exposure. Test two pack-outs and choose the safer result.

Q4: Is thermal testing worth it for smaller chocolate brands?

Oui. One validated warm-season SOP can prevent many refunds and repeat shipping costs.

Q5: What documents should a gel cooling pad chocolate manufacturer provide?

Seal integrity controls, traçabilité des lots, storage guidance, and clear non-conformance handling.

Q6: Can I use the same pack-out all year?

Généralement non. Keep it simple with two SOPs: warm season and mild season.

Q7: Are reusable gel pads practical for chocolate brands?

They work best in closed-loop routes. For D2C, single-use is often simpler.

Q8: What is the biggest sourcing mistake?

Buying by pad weight alone. You need performance inside your actual shipper, not in a brochure.

Résumé et recommandations

A gel cooling pad chocolate manufacturer helps you ship chocolate with fewer failures by stabilizing temperature swings and supporting a repeatable pack-out. Dans 2026, reliability comes from system thinking: pad design, isolation, placement, et formation. Use lane scoring to prioritize validation, then standardize with photo SOPs and weight checks. When your process is simple and repeatable, quality becomes predictable and costs become easier to control.

Next-Step Action Plan (CTA)

Score your lanes using the Lane Risk Score tool.

Request thermal curves and a recommended configuration in your shipper.

Pilot a warm-season pack-out and document it with photos.

Train once, then audit weekly with a weight check.

Scale using fewer SKUs and standardized pad footprints.

À propos du tempk

Et tempk, we support chocolate shippers with practical gel cooling solutions designed for real handling conditions. We focus on steady temperature buffering, durable seals, and SOP-friendly pack-out designs that reduce errors during peak season. We avoid overcomplicated setups and prioritize repeatable results that protect your product and your customer experience.

Appel à l'action: Share your carton size, temps de transit, and hottest destination region, and we will recommend a pack-out approach you can standardize.