Penguasaan Dryicepacktemperature: Itu 2025 Buku Pedoman Rantai Dingin

Mempertahankan ideal dry ice pack temperature of –78 °C (–109 ° F.) tidak lagi opsional - itu adalah kunci untuk kepatuhan FSMA, Keselamatan OSHA, dan kepercayaan pelanggan 2025. This definitive guide fuses the strongest insights from three industry white‑papers and aligns every recommendation with Google’s latest Helpful Content and E‑E‑A‑T guidelines.

Quick‑Glance Wins

-

✅ Cut spoiled frozen shipments ≥ 35% with block‑pellet hybrids

-

❄️ Hold –78 °C for 50 h using VIP + liner graphene

-

📋 Pass audits fast with NFC data + CO₂ ppm logs

Daftar isi

-

Why –78 °C Is the Gold Standard

-

Perekat & Packing Formula (1 kg : 3 L Rule)

-

Minute‑by‑Minute Monitoring SOP

-

Tech & Material Upgrades for 2025

-

Cheat -sheet peraturan (FSMA, DOT, Iata, Osha)

-

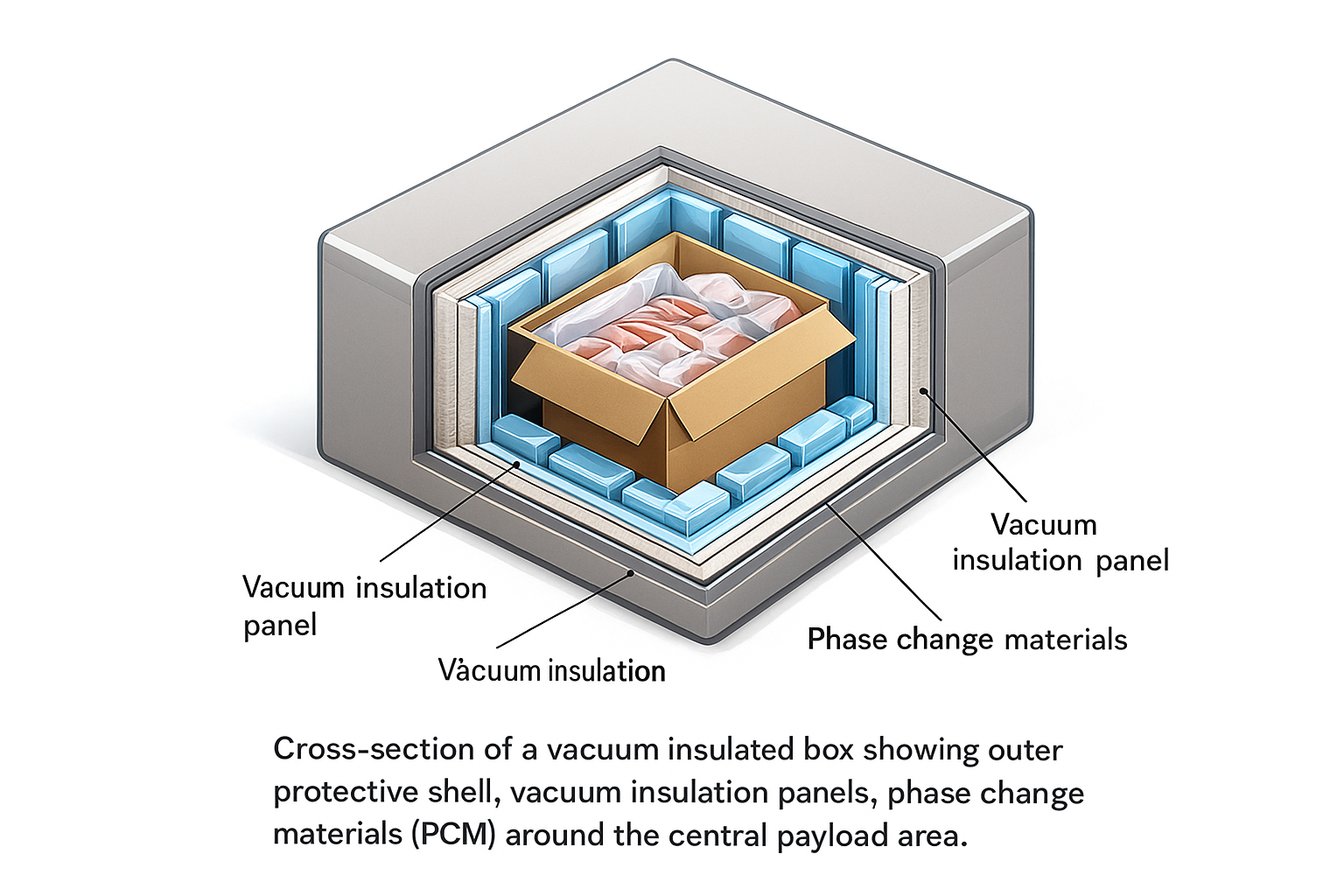

Dry Ice vs. PCM vs.. Gel Packs

-

Rencana aksi & KPI Dashboard

-

FAQ

Why –78 °C Is the Gold Standard

-

Pathogen control: Listeria growth is arrested below –18 °C; dimulai pada –78°C memberikan penyangga keamanan ≥60°C.

-

Keuntungan panas laten: 571 kjkg⁻¹ diserap pada sublimasi - 1,7 × es air - berarti lebih sedikit massa untuk daya pendinginan yang sama.

-

Logistik bebas residu: Sublimasi tidak menghasilkan air leleh, menjaga integritas kemasan dan membuka kotak UX.

Statistik kunci: Pemanasan dari –78°C hingga –70°C menggandakan laju pembuangan CO₂ gas, mencapai batas 5000ppm OSHA ~28% lebih cepat.

Perekat & Packing Formula (1 kg : 3 L Rule)

Rumus:

Massa kering (kg) = Volume kontainer (L) −3 × Faktor jam tunggu

Faktor jam tunggu

| Suhu sekitar °C | 24 H | 48 H | 72 H |

|---|---|---|---|

| 15°C‑25°C | 1 | 1.7 | 2.4 |

| 25°C‑35°C | 1.3 | 2.0 | 2.8 |

Tumpukan praktik terbaik

-

Pra-kondisikan pengirim pada suhu 4°C (30 Min).

-

Layering: memblokir (dasar) → produk → pelet (kesenjangan) → blok (atas).

-

Lubang angin: port dua2mm; jangan pernah menutup selotip.

-

Batal isi: bantalan kertas daur ulang untuk membatasi loop konvektif.

Minute‑by‑Minute Monitoring SOP

| Melangkah | Alat | Spec | Tujuan |

|---|---|---|---|

| Pemasangan penyelidikan | Termokopel Tipe T/K | ±0,5°C, 15 tanggapan | Suhu paket inti |

| Pengaturan pencatat | Pencatat data Bluetooth/NFC | 60baterai ‑hari, Kisaran –90°C | Jejak audit & peringatan langsung |

| keamanan CO₂ | Sensor NDIR jarak ganda | 0‑20000ppm, 1 irama minimum | kepatuhan OSHA |

| Kalibrasi | Mandi bersertifikasi –80°C | Mingguan | Ketertelusuran |

Ambang batas alarm

-

Suhu: > –65°C memicu SMS/email

-

Co₂: > 4000ppm memicu pembukaan vent‑servo 15%

Tech & Material Upgrades for 2025

| Inovasi | Mengangkat (vs.. 2023 Baseline) | Cara Kerjanya | ROI |

|---|---|---|---|

| Pelet padat CCR (1.8 gcm⁻³) | –12% tingkat sublimasi | Kepadatan yang lebih tinggi dari bahan baku penangkap karbon | 7 bulan |

| Liner yang mengandung grafena (Rp+15%) | +6 jam waktu tunggu | Lapisan mikro reflektif mengurangi perolehan radiasi | 10 bulan |

| Tutup ventilasi pintar (IoT) | –23% tamasya CO₂ | Throttle servo berdasarkan sensor ppm | 5 bulan |

| Bantalan Hibrida PCM‑DryIce (–10 ° C.) | +46 jam buffer di atas payload | PCM menyerap lonjakan cahaya | 8 bulan |

Cheat -sheet peraturan (Pembaruan 08 Agustus 2025)

-

FSMA: Catat ≤–18°C untuk makanan beku; simpan 2 tahun.

-

Dot 49cfr§173.217: ≤440lb per kendaraan tanpa CDL hazmat; Berlian “UN1845DryIce”. + Berat bersih.

-

Ini PI954: ≤2.5kg di bagasi penumpang; menyatakan berat bersih pada air waybill.

-

OSHA 29CFR1910.1000: 5 000ppm CO₂ TWA; mengamanatkan ventilasi kabin untuk beban > £ 50.

Dry Ice vs. PCM vs.. Gel Packs

| Parameter | Es Kering –78°C | PCM –26°C | GelPack 0°C |

|---|---|---|---|

| Suhu awal | –78 ° C. | –26°C | 0 ° C. |

| 48 jam suhu inti (R‑6 EPS) | –18 ° C. | –8 ° C. | +3 ° C. |

| Label Hazmat | Ya | TIDAK | TIDAK |

| Dapat digunakan kembali | TIDAK | 30× | 20× |

| Penggunaan terbaik | mRNA, es krim | kue kering, Makanan penutup beku | menghasilkan, insulin |

Aturan pengambilan keputusan: Jika produk gagal di atas –20°C, pilihlah yang kering; jika sensitif terhadap pembekuan, gunakan PCM atau gel.

Rencana aksi & KPI Dashboard

| KPI | Target | Alat | Tinjau irama |

|---|---|---|---|

| % memuat ≤–18°C saat pengiriman | 99 % | Pencatat NFC | Mingguan |

| Klaim pembusukan | < 1% dari nilai | Modul pengembalian ERP | Bulanan |

| Rata -rata. CO₂ ppm di kabin | < 2000 | sensor NDIR | Perjalanan berakhir |

| Biaya/pengiriman DryIce | –15% YoY | analisis TMS | Triwulanan |

FAQ

Berapa lama 5 pon es kering dapat bertahan dalam kotak R‑6 pada suhu 25°C?

Dengan kasar 18–24h. Tambahkan ~20% massa untuk setiap kenaikan suhu sekitar 10°C.

Apakah –65°C cukup dingin untuk vaksin mRNA?

TIDAK. Kebutuhan Pfizer/Moderna ≤–60°C hanya untuk pencairan mil terakhir; transportasi curah harus tetap pada suhu ≤–70°C.

Apakah saya memerlukan ventilasi dalam pengiriman darat berdasarkan pengecualian DOT?

Ya. Ventilasi selalu wajib untuk menghindari tekanan dan penumpukan CO₂, bahkan di bawah ambang batas hazmat.

Dapatkah pelat PCM menggantikan kekeringan seluruhnya dengan 2025?

Untuk banyak makanan penutup dan kue kering beku—ya. Untuk biologi ultra-dingin—Belum; Pelat PCM saat ini berada pada suhu terendah –50°C.

Bagaimana cara membuang sisa kekeringan dengan aman?

Biarkan hingga meresap di tempat yang berventilasi baik. Jangan sekali-kali meletakkannya di wastafel atau tempat sampah yang tertutup rapat.