Saat pengiriman salmon segar atau vaksin yang menyelamatkan jiwa menempuh ratusan mil, Satu hal yang paling penting: Menjaga mereka pada suhu yang tepat. Memasuki batu bata paket es-kasar, blok yang dapat digunakan kembali yang dirancang untuk memberikan stabil, Pendinginan yang andal dari awal hingga akhir. Tidak seperti paket gel fleksibel yang bergeser dengan perjalanan, Batu bata yang kaku ini menggunakan sains pintar untuk mempertahankan “zona dingin yang konsisten,“Membuat mereka menjadi game-changer untuk makanan, farmasi, dan tim logistik sama.

Apa itu batu bata paket es, dan bagaimana mereka bekerja?

Batu bata paket es seperti "baterai pendingin" portabel. Mereka kaku, Kerang plastik tingkat makanan (Seringkali polietilen dengan kepadatan tinggi) diisi dengan gel pendingin khusus atau bahan perubahan fase (PCM). Saat membeku, Gel ini menyerap panas secara perlahan dan mantap, melepaskannya selama berjam -jam atau bahkan berhari -hari untuk menjaga kargo tetap dingin.

Keajaiban terletak pada merekaDesain yang kaku: Tidak ada kendur, tidak bocor, dan tidak ada kristal es yang berantakan. Stabilitas ini memastikan kargo Anda tetap dalam kisaran suhu yang ketat - bahkan selama pengangkutan panjang atau penundaan yang tidak terduga.

Mengapa Batu Bata Paket Es Mengalahkan Paket Fleksibel untuk Keandalan Rantai Dingin

1. Pendinginan yang konsisten, Tidak ada kejutan

Paket gel yang fleksibel sesuai dengan kargo tetapi dapat bergeser, Membuat hot spot. Batu bata es, dengan bentuk padat, mendistribusikan dingin secara merata. Ini berarti:

- Makanan tetap garing: Salad sayuran tetap segar untuk 48+ jam, Bahkan pada hari -hari yang panas.

- Obat -obatan tetap kuat: Vaksin dan Biologi mempertahankan kisaran 2-8 ° C tanpa lonjakan suhu.

2. Desain Ramah Logistik

Tumpukan batu bata dengan rapi, Mengurangi ruang kosong dalam pengiriman dan mencegah kerusakan produk. Gudang juga mencintai mereka - mereka membeku lebih cepat (Terima kasih kepada penggemar berkecepatan tinggi) dan ribuan perjalanan terakhir, Memotong limbah dan biaya.

3. Berkelanjutan & Hemat biaya

Batu bata es modern menggunakan tidak beracun, PCM dan cangkang yang dapat didaur ulang yang terurai secara hayati. Menggunakan kembali mereka memotong limbah plastik sekali pakai, sementara umur panjang mereka menurunkan biaya jangka panjang untuk bisnis.

Memilih batu bata paket es yang tepat

Untuk mendapatkan hasil terbaik, Cocokkan batu bata dengan kargo Anda:

- Kebutuhan suhu: Bata 0 ° C bekerja untuk es krim; A +5 ° C Brick Suits Biologics Tropis.

- Ukuran penting: Gunakan batu bata ramping untuk pesanan kecil atau batu bata listrik untuk pengiriman curah.

- Sertifikasi: Cari FDA yang disetujui (tidak beracun) dan ISTA diuji (dapat diandalkan untuk pengiriman) opsi.

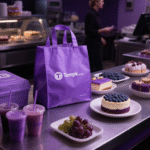

Mengapa Tempk Ice Pack Bricks menonjol

Batu bata Tempk membawa keandalan ke tingkat berikutnya dengan fitur yang dibangun untuk logistik dunia nyata:

1. Lebih keras dari sebelumnya

Cangkang hdpe grade makanan mereka 30% lebih tebal dari standar, mengangkat tetes, Forklift Benjol, dan penanganan kasar. Tidak ada kebocoran, tidak ada pecah - hanya pendinginan yang stabil.

2. Dingin lebih lama

PCM milik Tempk 15% daya pendinginan lebih banyak, menjaga kargo tetap dingin 72+ Jam dalam 30 ° C panas. Itu cukup untuk pengiriman lintas negara atau lari mil terakhir.

3. Kustom cocok untuk bisnis Anda

Membutuhkan ukuran yang unik, warna, atau branding? TEMPK memungkinkan Anda menyesuaikan shell dan menambahkan ID yang tidak terputus untuk pelacakan inventaris. Plus, Desain Modular Membiarkan Anda Menukar Ukuran Tanpa Mendesain Masuk Mendesain.

4. Eco-Consent oleh Desain

Kerang yang dapat digunakan kembali mengurangi limbah plastik 70% lebih dari paket sekali pakai. Beberapa model bahkan menggunakan PCM berbasis bio, mengubah limbah menjadi nilai di akhir kehidupan.

Pikiran terakhir

Di rantai dingin, Konsistensi adalah raja. Batu bata paket es memberikan konsistensi itu - tidak peduli kargo, rute, atau cuaca. Dengan Tempk sulit, tepat, dan desain berkelanjutan, Anda tidak hanya menjaga keadaan dingin - Anda menyimpannya segar, aman, Dan menguntungkan.

Karena saat mudah rusak datang sebagaimana dimaksud, Semua orang menang.