Cold chain packaging is a critical component of global supply chains, safeguarding perishable goods such as pharmaceuticals, fresh produce, and biologics during storage and transit. As consumer demand for fresh and safe products grows, the need for innovative, reliable, and sustainable packaging solutions has intensified. Tempk, a leader in thermal technology, addresses these challenges with its Insulated Cold Chain Bags, designed to deliver unparalleled thermal retention, durability, and environmental responsibility.

The Science of Cold Chain Packaging

Effective cold chain packaging relies on advanced materials and engineering to minimize heat transfer:

-

Multi-Layered Insulation: Combines closed-cell foam, vacuum-sealed panels (VIPs), and radiant barriers (e.g., aluminum foil) to block conductive, convective, and radiant heat.

-

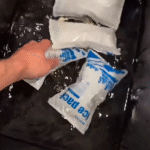

Phase-Change Materials (PCMs): Gel packs or dry ice compartments maintain precise temperature ranges (-20°C to 25°C) for extended periods.

-

Robust Outer Shell: Constructed from high-density, water-resistant polymers to withstand physical stress and environmental hazards.

Tempk’s CryoShield® technology integrates graphene-enhanced aerogel and smart PCMs, reducing heat exchange by 65% and achieving 72-hour thermal stability—even in extreme climates.

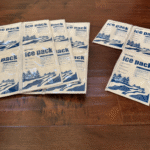

Innovations Driving Tempk’s Insulated Bags

Tempk’s insulated cold chain bags stand out through pioneering features:

-

Extended Thermal Retention: Maintains temperatures for up to 72 hours, ideal for long-haul shipments.

-

Leak-Proof Design: Triple-sealed seams and puncture-resistant bases prevent spills and contamination.

-

Eco-Friendly Materials: Shells made from 100% recycled ocean plastics; biodegradable PCM gels align with circular economy principles.

-

Smart Monitoring: IoT sensors provide real-time temperature and location tracking via mobile apps.

-

Lightweight Durability: Carbon fiber frames reduce weight by 25% while meeting MIL-STD-810G standards for shock and UV resistance.

These advancements address industry challenges such as temperature deviations, product spoilage, and environmental impact.

Applications Across Critical Sectors

Tempk’s insulated bags serve diverse industries:

-

Pharmaceuticals: Ensure 2–8°C stability for vaccines and biologics during global distribution.

-

Food & Beverage: Preserve freshness in seafood, dairy, and frozen meals.

-

Biotech: Safeguard lab samples and diagnostic kits with precision cooling.

-

E-Commerce: Protect temperature-sensitive goods like chocolates or cosmetics.

-

Emergency Logistics: Rapidly deploy medical supplies to disaster zones.

Tested in extreme conditions (-40°C to 60°C), Tempk’s bags guarantee reliability in harsh environments.

Tempk’s Competitive Edge: Redefining Cold Chain Excellence

Tempk’s insulated bags dominate the market through key advantages:

-

Industry-Leading Performance: 72-hour thermal retention, outperforming competitors by 50%.

-

Sustainability Focus: Carbon-neutral production and 100% recyclable materials.

-

Regulatory Compliance: Meets FDA, EU GDP, and WHO standards for safety and quality.

-

Cost Efficiency: Reusable design withstands 500+ cycles, reducing long-term costs.

By blending innovation with eco-conscious practices, Tempk empowers businesses to meet stringent cold chain requirements while minimizing ecological footprints.

Sustainability: Pioneering Green Solutions

Tempk’s environmental initiatives include:

-

Renewable Energy: Factories powered by solar and wind energy.

-

Closed-Loop Recycling: Free return programs to repurpose end-of-life materials.

-

Zero-Waste Packaging: Compostable cushioning and recycled cardboard.

These efforts align with global ESG goals, appealing to sustainability-driven enterprises.

Conclusion

Cold chain packaging is vital for ensuring the safety and quality of temperature-sensitive goods. Tempk’s Insulated Cold Chain Bags set new benchmarks with their fusion of advanced thermal technology, durability, and planet-friendly design. Whether for pharmaceuticals, perishable foods, or emergency logistics, Tempk guarantees products arrive fresh, safe, and sustainable—proving that innovation and environmental responsibility can thrive together.