When it comes to shipping perishable goods, maintaining the right temperature is crucial. Dry ice for coolers offers an effective solution for temperature-controlled shipping. This article explains how dry ice works in coolers, the advantages it provides, and why it’s a preferred choice for businesses dealing with sensitive products.

This article will address key questions about:

-

How does dry ice work in coolers for shipping?

-

What are the key benefits of using dry ice for coolers?

-

How does dry ice improve shipping for perishable goods?

-

Why is dry ice the go-to cooling solution for businesses?

How Does Dry Ice Work in Coolers for Shipping?

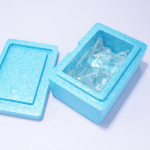

Dry ice, the solid form of carbon dioxide, is a highly effective cooling agent for shipments that require low temperatures. When placed in a cooler, dry ice maintains a sub-zero environment, perfect for preserving the quality of temperature-sensitive goods. Unlike regular ice, dry ice sublimates, meaning it changes from a solid to a gas without turning into water, preventing moisture from compromising the goods.

This unique property makes dry ice especially valuable for long-distance shipping, where maintaining a consistent temperature is essential.

Key Benefits of Using Dry Ice for Coolers

-

Longer Cooling Duration: Dry ice lasts longer than regular ice, keeping products at the required temperature for 24-72 hours.

-

No Water Damage: Since it doesn’t melt into water, dry ice avoids the risk of moisture damage to products.

-

Ideal for Remote Locations: Dry ice allows businesses to ship perishable goods to remote or international destinations without worrying about temperature fluctuations.

| Cooling Type | Dry Ice Temperature | Cooling Duration | Ideal Products |

|---|---|---|---|

| Meat and Seafood | -78.5°C (-109.3°F) | 24-72 hours | Preserves freshness |

| Frozen Foods | -78.5°C (-109.3°F) | 48-72 hours | Maintains frozen state |

| Fresh Produce | -18°C to -30°C | 24-48 hours | Extends shelf life |

What Are the Key Benefits of Dry Ice for Coolers?

Using dry ice for coolers offers several advantages, particularly when it comes to preserving perishable goods. The key benefits include:

-

Extended Cooling Time: Dry ice provides consistent, long-lasting cooling, essential for maintaining the integrity of temperature-sensitive products.

-

Prevention of Thawing: Dry ice helps to prevent thawing during shipments, making it perfect for frozen foods and other items that need to stay at a low temperature.

-

Safe for Transportation: Dry ice doesn’t melt into water, so it won’t damage the contents of the cooler. This is particularly important for meat, seafood, and other products sensitive to moisture.

Best Practices for Using Dry Ice in Coolers

-

Proper Ventilation: Dry ice sublimates into carbon dioxide gas, so it’s essential to ensure proper ventilation in the cooler to avoid gas buildup.

-

Temperature Monitoring: Use temperature monitoring devices to track the cooler’s internal environment during transit, ensuring the product stays within the correct temperature range.

-

Adequate Insulation: Pair dry ice with high-quality insulated coolers to maximize cooling efficiency and ensure a consistent temperature for the duration of the shipment.

Real-World Example: A seafood distributor used dry ice to ship fresh fish across state lines. The dry ice maintained the required freezing temperature for 48 hours, ensuring the products arrived in pristine condition, with no signs of thawing.

How Does Dry Ice Improve Shipping for Perishable Goods?

Shipping perishable goods requires careful attention to temperature control. Dry ice offers the perfect solution to maintain the cold chain during transport. Here’s how it helps:

-

Prevents Temperature Fluctuations: Dry ice ensures a stable temperature, preventing variations that could compromise product quality.

-

Keeps Products Frozen: For frozen items like meat, seafood, and ice cream, dry ice keeps them frozen solid, reducing the risk of thawing during the journey.

-

Cost-Effective for Long Shipments: Dry ice is cost-effective for long-distance shipments, as it lasts longer than regular ice and doesn’t require constant replenishment.

Dry Ice vs. Regular Ice: Which is Better for Coolers?

| Feature | Dry Ice | Regular Ice |

|---|---|---|

| Cooling Duration | 24-72 hours | 12-24 hours |

| Moisture | Sublimates into gas | Melts into water |

| Cooling Efficiency | More efficient | Less efficient |

Why Is Dry Ice the Go-To Cooling Solution for Businesses?

For businesses in the food industry, ensuring that products reach their destination in perfect condition is essential. Dry ice offers several reasons why it’s the preferred cooling method:

-

Reliability: Dry ice keeps products cool consistently, even in challenging shipping environments.

-

Versatility: It can be used for a variety of perishable goods, including frozen foods, fresh produce, and pharmaceuticals.

-

Eco-Friendly: Dry ice is an environmentally friendly option because it doesn’t generate water waste, which is particularly beneficial for eco-conscious businesses.

Dry Ice Packaging Tips for Maximum Efficiency

-

Use the Right Amount: The amount of dry ice required depends on the shipment duration and type of product being shipped. Always calculate the ideal quantity for optimal results.

-

Combine with Insulation: Use insulated containers to maintain the low temperature for as long as possible, and prevent unnecessary energy loss.

Real-World Example: A chocolate manufacturer uses dry ice to ship premium products to international clients. The dry ice ensures the chocolates remain in perfect condition, even in high-temperature environments, making it a preferred choice for the company.

2025 Trends in Dry Ice Packaging

In 2025, the use of dry ice in cold chain packaging continues to evolve, especially with the demand for sustainable and efficient cooling solutions. Key trends include:

-

Sustainable Dry Ice: Companies are exploring ways to reduce the carbon footprint of dry ice production.

-

Smart Packaging Solutions: Temperature-sensitive shipments are becoming more efficient with the integration of smart sensors that monitor and track the temperature in real-time.

Latest Developments

-

Green Alternatives: Research into greener alternatives to dry ice is growing, with companies aiming to reduce their environmental impact while maintaining high levels of cooling efficiency.

-

Advanced Insulation: The development of advanced insulation materials ensures better performance for extended transit times.

Frequently Asked Questions {#faq}

How long does dry ice keep food cold in a cooler?

Dry ice can keep food cold for up to 72 hours, depending on the amount used and the type of food being shipped.

Can dry ice be used for all types of food?

Yes, dry ice is ideal for keeping a wide variety of perishable goods cool, including meat, seafood, dairy, and frozen foods.

Where can I buy dry ice for shipping food?

Dry ice is available at local suppliers, including grocery stores, gas stations, and specialized distributors.

Summary and Recommendations

Using dry ice for coolers provides businesses with a reliable and efficient solution for shipping temperature-sensitive goods. The benefits of dry ice, including longer cooling durations, moisture control, and cost-effectiveness, make it a preferred choice for perishable food transport.

Next Steps: To improve your shipping process, consider incorporating dry ice into your packaging strategy. Contact a trusted dry ice supplier to discuss how to maximize its potential for your business.

About Tempk

At Tempk, we specialize in providing high-quality cold chain solutions, ensuring the safe and efficient transport of perishable goods. Our dry ice packaging ensures your products stay fresh, from shipment to delivery.

Contact us today for more information on how we can help your business thrive with effective temperature control solutions.