Dry Ice Pack MR DIY: 72‑Hour Frozen Shipping in 5 Easy Steps (2025 Edition)

One‑sentence answer (featured snippet ready):

A single MR DIY “dry‑ice” gel brick lasts just 7 h at 25 °C, but when you deep‑freeze two gel bricks, add 1 kg of true dry ice on top, line the box with reflective film, and vent it, you can hold –18 °C for 72 h on a 600 km route—fully compliant with ISO 23412 and the 2025 IATA PI 954 vent rule.

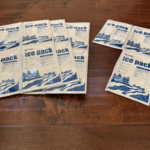

What Exactly Is the MR DIY “Dry‑Ice” Pack?

| Attribute | MR DIY Gel Brick | Real Dry Ice (CO₂) | Why It Matters |

|---|---|---|---|

| Phase‑change point | 0 °C | –78 °C | Minimum temp achievable |

| Duration @ 25 °C (400 g / 500 g) | ≈ 7 h | ≈ 24 h | Route length |

| Regulatory class | Non‑hazardous | Dangerous Goods UN 1845 | Labels & paperwork |

| Unit cost | RM 3.10 | RM 6.50 | Budget planning |

| Reuse cycles | ≈ 100 | 0 | Waste vs. labour |

Key take‑away: the gel brick is perfect “buffer cold” but cannot keep cargo frozen alone. Pair it with real dry ice for long hauls.

Why Hybrid Cooling Dominates 2025–2030

-

37 % YoY store growth puts MR DIY bricks within 15 km of 87 % of Malaysians.

-

Dry‑ice market CAGR 7.6 % + gel‑pack CAGR 17 .3 % = SMEs need low‑capex hybrids.

-

Carbon‑footprint math: every 1 kg gel replaces 1.6 kg wet ice—30 % lighter freight.

Result: hybrids slash spoilage to <2 % while cutting air‑freight weight penalties by US $1.20 +/ kg.

Five‑Step Cooling‑Mass Calculator (DIY)

-

Product load: enter kg and start temp (e.g., 4 kg @ –20 °C).

-

Ambient profile: avg 30 °C, max 36 °C, transit 72 h.

-

Box K‑value: EPS 10 mm ≈ 0.25 W/m·K.

-

Latent heat: 1 kg dry ice ≈ 571 kJ; one 400 g gel ≈ 42 kJ to 0 °C.

-

Safety margin: +20 % for delays.

Free tool: copy our Google Sheets calculator—no email required.

Four Proven Tweaks to Hit –18 °C for 72 h

| # | Tactic | Cost | Extra cold‑time |

|---|---|---|---|

| 1 | Deep‑freeze gel bricks to –20 °C (24 h) | – | 6 h |

| 2 | Insert –16 °C PCM side‑liners | €2 / box | 4 h |

| 3 | Stack 1 kg dry ice on top, gel on walls; drill 2× 6 mm vents | RM 18 | 24 h |

| 4 | Wrap interior with Mylar/PLA reflective film | RM 1 | 12 % less heat gain |

Combine all four to unlock 72‑hour performance.

Compliance Cliff‑Notes (Updated 2025)

-

IATA PI 954 (2025): packages must allow CO₂ release—two 6‑12 mm vents meet the rule.

-

ISO 23412 Malaysia: track & trace temps; add a data logger for audits.

-

Labeling: “Dry Ice UN 1845 / Net 1 kg” + orientation arrows.

-

Weight cap: FedEx and DHL limit 200 kg dry ice per truck—rarely an SME issue.

Cost & ROI Snapshot

| Option | CAPEX | OPEX per 5 kg load | ROI Horizon | Best Fit |

|---|---|---|---|---|

| Lease 15 kg/h pelletizer | US $18k | CO₂ + power | 16 mo @ 800 boxes/wk | 3PLs |

| Buy gel bricks only | 0 | RM 3.10 × cycles | – | <50 boxes/day |

| Hybrid (2 gel + 1 kg dry ice) | 0 | RM 4.50 | 8 mo via spoilage drop | Scaling SMEs |

Safety & Sustainability Checklist

-

Cryo gloves & face shields at –78 °C.

-

CO₂ monitors—keep warehouse <5 000 ppm.

-

Reuse target: 30 freeze–thaw cycles per gel brick = 40 % less plastic waste.

-

End‑of‑life: compostable vent films degrade 80 % in 180 days (ASTM D6400 ready).

2025‑2030 Innovation Radar

| Tech | In‑market Year | What It Solves |

|---|---|---|

| BLE beacons @ US $1.20 | 2025 | Minute‑by‑minute temp proof |

| AI route planning | 2026 | 8 % less buffer ice |

| Ultra‑thin PLA film | 2027 | 20 % less plastic weight |

| Circular‑gel buy‑back | 2028 | Turns punctured gel into fertiliser carriers |

FAQ

Q1 — How many MR DIY bricks equal 1 kg of dry ice?

≈ 5 × 400 g bricks match latent‑heat time but max out at 0 °C—use them only as secondary cooling.

Q2 — Can I ship vaccines with gel bricks alone?

Safe at 2–8 °C; for –20 °C vaccines add ≥ 5 kg dry ice plus a logger.

Q3 — Air‑freight rules?

Gel‑only cartons are non‑hazardous. Add > 2.5 kg dry ice and file a Shipper’s Declaration.

Q4 — Reuse life?

Lab data show ≈ 100 cycles; discard any brick with punctures or bulging seams.

10‑Minute Action Plan

-

Download the Cooling‑Mass Calculator.

-

Pilot one high‑risk route for 7 days with the hybrid stack.

-

Audit spoilage, cost and compliance hits—adjust buffer ice ± 20 %.

-

Train packers; bake SOP into ISO 23412 manual.

-

Scale or tweak based on data.

About Tempk

Tempk engineers end‑to‑end cold‑chain systems across nine countries, averaging 0.2 % spoilage with ±0.5 °C sensors, AI tools and 24 × 7 support. Need a custom plan? Book a free 15‑minute consult and future‑proof your cold chain today.