How to Pack Fish in Dry Ice the Right Way (2025)

If you’re asking how to pack fish in dry ice, here’s the short answer: use a thick insulated shipper, vent the package, layer dry ice above and below the fish, and mark “Dry Ice/UN1845” with net weight. Plan 5–10 lb per 24 hours, add a buffer day, and follow the 2.5 kg airline limit for baggage. You’ll keep seafood solid and compliant on trips up to 72 hours.

-

Gear that works: the exact cooler, liners, and labels for how to pack fish in dry ice on 24–72h routes

-

Right amount of dry ice: a quick planner for long‑haul shipments and hot weather

-

Airline and courier compliance: practical UN1845 labeling and venting that pass checks

-

Step‑by‑step packout: a repeatable method that prevents leaks, odors, and thaw

-

Trends for 2025: how better insulation and low‑cost loggers cut dry ice weight

What gear do you need to pack fish in dry ice?

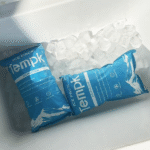

Short list: insulated shipper (≥1–2″ walls), rigid outer box, food‑safe vacuum bags, absorbent pad, vapor barrier liner, dry ice (blocks or large pellets), void fill, insulated gloves, and “Dry Ice/UN1845 + net kg” marks on the outside.

Why it works: thick foam or VIP panels slow heat gain; vacuum bags block odors and freezer burn; the liner stops moisture from softening the carton; venting prevents CO₂ pressure buildup. Start fish fully frozen, or fresh fish at ~32°F (0°C). These small choices keep temperatures stable and reduce claims.

Dry ice vs. gel packs—when to use each for seafood?

Bottom line: for how to pack fish in dry ice on multi‑day, frozen lanes, use dry ice as the primary coolant. Gel packs are great as support (smoother warm‑up curve) or for chilled‑not‑frozen deliveries. If you must keep fish unfrozen, buffer the dry ice with cardboard and use less.

| Packout Type | Dry Ice per 24h | Typical Duration | What it means for you |

|---|---|---|---|

| EPS foam 1–1.5″ | 8–12 lb | 24–48 h | Budget friendly; add buffer in summer. |

| EPS foam 2″ | 6–10 lb | 48–72 h | Good for weekends if pre‑chilled. |

| VIP panels | 4–8 lb | 72 h+ | Premium; best for hot routes or long customs. |

Practical tips you can apply today

-

Pre‑chill everything: fish, shipper, and void fill.

-

Top + bottom layers: put some dry ice under and more on top; cold CO₂ sinks.

-

Avoid airtight seals: leave a vent path; never shrink‑wrap the lid.

-

Write net kg: regulators expect kilograms on the label.

Real‑world case: 20 lb of salmon in a 2″ foam shipper with 18 lb of dry ice (split top/bottom) arrived after ~40 hours at −12 °C by data logger—no thaw and no leakage.

How much dry ice do you need to pack fish in dry ice for 24–72 hours?

Rule of thumb: 5–10 lb per 24 hours, then add a buffer day for delays. Use the higher end for pellets, thin insulation, frequent openings, or hot weather.

Why this range works: sublimation depends on surface area, insulation, and ambient heat. Thicker foam or VIP slows loss; minimizing voids reduces convection. Planning with a baseline plus buffer keeps loads frozen even when routes slip.

Quick Dry‑Ice Planner (copy/paste)

How to pack fish in dry ice step by step?

Essentials: Freeze or chill first, double‑bag, line the box, dry ice bottom, fish in the middle, dry ice top, fill voids, close vented, then mark UN1845 + net kg.

Details that prevent problems: use 3–4 mil vacuum pouches; add a thin cardboard sheet between dry ice and fish to prevent surface burn; keep labels on one panel (“Dry Ice/Carbon dioxide, solid,” UN1845, net kg); wear insulated gloves and eye protection.

Step‑by‑step checklist

-

Pre‑condition fish (frozen, or fresh at ~32°F/0°C).

-

Vacuum‑seal portions; double‑bag oily species.

-

Line the shipper with absorbent + vapor barrier; add a corrugated pad.

-

Add lower dry‑ice layer (blocks last longer than pellets).

-

Load fish flat with minimal air gaps.

-

Add upper dry‑ice layer for downward cold flow.

-

Fill voids with kraft/bubble; avoid movement.

-

Close vented—never airtight; secure the outer carton.

-

Label: “Dry Ice,” “UN1845,” and net kg on the same face.

Can you pack fish in dry ice for airline travel?

Yes—within limits. Passengers may carry up to 2.5 kg (5.5 lb) of dry ice per person per package in vented packaging with airline approval. Mark “Dry Ice/Carbon dioxide, solid,” UN1845, net kg. Use a rigid, leak‑resistant cooler inside a bag or box, and keep the lid not airtight.

Airport mini‑checklist

-

Fish frozen/vacuum‑sealed; no free water (“wet ice”).

-

Rigid cooler + outer carton; leave a vent path.

-

Total dry ice ≤2.5 kg; declare at check‑in.

How to pack fish in dry ice for courier shipping (FedEx/UPS/USPS)?

Markings and venting win approvals. Put proper shipping name, UN1845, Class 9 mark, and net kg on a single vertical panel; do not seal the package airtight. Choose the shortest viable service—less time means less dry ice.

Documentation quick‑reference

-

Proper name: “Dry Ice” or “Carbon dioxide, solid.”

-

UN number: UN1845; Class: 9 (Miscellaneous).

-

Net dry ice weight in kg on the box and (if applicable) on the airway bill.

-

Addresses: shipper and consignee clearly printed.

2025 trends: how to pack fish in dry ice better with new tech

What’s new in 2025: updated airline acceptance checklists emphasize net‑kg markings and label placement, while VIP panels and low‑cost loggers reduce dry‑ice loads and prove temperature control. Consumer demand for “dock‑to‑door in two days” is pushing reusable insulation and smarter routing.

Latest developments at a glance

-

Smarter monitoring: pocket‑size loggers give arrival proof and speed claims.

-

Insulation upgrades: VIP/lightweight hybrids achieve the same hold time with less ice.

-

Operational rigor: carriers scrutinize venting and UN1845 marks more consistently.

Market insight: seafood exporters using verified logs and clear UN1845 labeling report fewer delays and credits. Optimizing insulation often saves more weight (and cost) than over‑icing.

FAQ: how to pack fish in dry ice

Q1. How much dry ice for a 48‑hour shipment?

Plan 16–24 lb for 1–1.5″ EPS, 12–18 lb for 2″ EPS, or 10–16 lb for VIP, plus ~5 lb buffer.

Q2. Can I tape a cooler shut to “trap the cold”?

No. Airtight is unsafe. Dry ice vents CO₂; packages must release gas.

Q3. What temperatures should I target?

Keep fresh fish near 32°F (0°C); ensure ≤40°F (4.4°C) in handling. Keep frozen fish rock solid.

Q4. Can I combine gel packs with dry ice?

Yes. Gel packs smooth temperature swings but won’t keep fish frozen alone.

Q5. What goes on the label?

**“Dry Ice/Carbon dioxide, solid,” UN1845, and net kilograms of dry ice—clearly visible on one face.

Summary: how to pack fish in dry ice like a pro

Remember the four moves: start cold, build a vented insulated package, allocate 5–10 lb per day plus buffer, and mark UN1845 + net kg. Layer dry ice top and bottom, fill voids, and pick the shortest service that fits your lane. Follow these basics and your seafood arrives frozen, clean, and compliant.

Next steps (CTA):

-

Use the Quick Dry‑Ice Planner above for your route.

-

Pick a 2″ EPS or VIP shipper for 48–72h lanes.

-

Download a printable UN1845/Class 9 panel and packout checklist.

-

Talk to Tempk for a lane‑specific blueprint and SOP.

About Tempk

We design practical cold‑chain playbooks and packaging for seafood and specialty foods. Our tested 24–72h shippers use smart vent paths, moisture control, and right‑sized dry ice to keep payloads solid while cutting waste. We back deployments with SOPs, UN1845 label sets, and acceptance checklists that reduce claims and speed hand‑offs.

Ready to optimize a route? Get a free dry‑ice sizing plan and packout template for your next shipment.