How to Pack Dry Ice Cooler for 24–72 Hours?

Updated: September 1, 2025. If you need to pack dry ice cooler for a weekend trip, outage, or air shipment, this guide shows you the safest, simplest path. Plan 5–10 lb per 24 h as a baseline, keep packaging vented, and follow the 2.5 kg airline rule for passengers. You’ll size the load, avoid freeze damage, and stay compliant—without guesswork.

-

How do you pack dry ice cooler step by step? Practical steps and a checklist

-

How much dry ice is enough for your cooler? Quick estimator and table

-

Dry ice vs gel packs—when should you not pack dry ice cooler? Risk-based choices

-

Is it legal to pack dry ice cooler for air and ground? Labels and limits

-

What can go wrong when you pack dry ice cooler? Safety, venting, and fixes

How do you pack dry ice cooler step by step?

Start cold, wrap blocks, place for your goal, fill voids, and vent the container. Use insulated gloves and eye protection. Put dry ice on top to keep goods frozen hard; put it below a barrier when you want items only chilled. Never seal the lid airtight. These small moves extend hold time and cut risk.

Explain it like a field routine. Pre-chill the cooler for 2–12 hours so the dry ice cools product, not plastic. Wrap each block in paper to slow sublimation and prevent “freezer burn.” If you pack dry ice cooler for mixed loads, split blocks top and bottom and add a thin cardboard or towel barrier. Keep the lid closed between access—air is the enemy of hold time.

Venting and placement for long holds

Vent, don’t plug. CO₂ gas must escape. Aim for a loose lid fit or a vent channel. Place dry ice on top when the target must remain rock-solid; cold air sinks and blankets the load. For chilled layers, use dry ice on bottom with a barrier and regular ice on top. This balance avoids freeze damage to produce or dairy.

| Pack Goal | Dry Ice Placement | Barrier / Add‑ons | What It Means for You |

|---|---|---|---|

| Frozen solid | Top layer | Thin cardboard or towel | Cold air sinks; best for meats, ice cream |

| Chilled (1–4 °C) | Bottom layer | Barrier + regular ice above | Prevents surface freezing on produce |

| Mixed load | Split top/bottom | Gel packs near “chill‑only” zones | Frozen stays hard; drinks stay cold |

Practical tips and suggestions

-

Car transport: Crack windows; do not use recirculate mode for long drives.

-

Handling: Wear insulated gloves; avoid bare-hand contact.

-

Packing: Fill voids with paper; keep the cooler shaded and closed.

Field case: A 48‑qt hard cooler with 12 lb wrapped blocks, pre‑chilled and vented, kept dairy and frozen desserts solid for two market days with no lid deformation and normal CO₂ venting.

How much dry ice do you need to pack dry ice cooler?

Baseline: 5–10 lb per 24 h for ~25‑qt volume, then scale for size, heat, and opening frequency. Big blocks last longer than pellets. Pre-chilling can save several pounds on day one.

Think of demand as two knobs: heat and access. Sun and frequent openings raise sublimation. Shade, tight packing, and a full cooler slow it down. Use the quick rule below, then cross‑check with the sizing table.

Quick estimator (copy/paste)

| Cooler Size | Baseline Multiplier | 24 h Plan | 48 h Plan | For You |

|---|---|---|---|---|

| 25 qt | ×1.0 | 7–10 lb | 14–20 lb | Short trips; minimal opens |

| 48 qt | ×1.9 | 14–20 lb | 28–40 lb | Weekend trips; pre‑chill |

| 65 qt | ×2.6 | 18–26 lb | 36–52 lb | Guides / family groups |

| 100 qt | ×4.0 | 30–40 lb | 60–80 lb | Multi‑day; plan access windows |

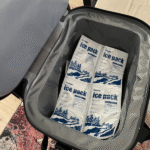

Dry ice vs gel packs—when should you not pack dry ice cooler?

Use dry ice for frozen targets; use gel or PCM when you must avoid freezing. Dry ice sits at −78.5 °C and will freeze anything it touches. Gel packs and PCMs hold warmer plateaus, ideal for 2–8 °C or controlled room temperature.

If you only need refrigerator cold for chocolates or produce, packing dry ice cooler is overkill and risks freeze damage. For “ice‑cream hard” outcomes across 24–72 h, dry ice is the right tool. For regulated 2–8 °C goods, choose qualified packaging and PCMs that match the temperature band.

Block vs pellet vs gel at a glance

| Cooling Choice | Typical Window | Notes | What It Means for You |

|---|---|---|---|

| Block dry ice | 48–72 h | Low surface area; slower loss | Longer trips; fewer lid opens |

| Pellet dry ice | 12–36 h | Fast pull‑down; fills voids | Quick starts; top‑off strategy |

| Gel / PCM packs | 12–96 h (band‑dependent) | Warmer plateau; reusable | Chilled shipments without freezing |

Actionable tips

-

Sensitive items: Add a barrier and test a small packout first.

-

Mixed loads: Use gel for “do‑not‑freeze” zones and blocks for frozen goods.

-

Cost control: One big block outlasts many pellets in the same mass.

Is it legal to pack dry ice cooler for air or ground?

Yes—with conditions. For air cargo, mark UN1845, use the Class 9 label, and indicate net mass (kg); follow operator rules (e.g., IATA PI 954). For passenger baggage, most airlines allow ≤2.5 kg (5.5 lb) per person in vented packaging with approval. For domestic ground, carriers often simplify documents but still require correct marks and venting.

Keep it simple: print “Dry Ice” or “Carbon dioxide, solid,” add net kg of dry ice, ensure venting, and follow the carrier checklist. If in doubt, call your operator before tender.

What can go wrong when you pack dry ice cooler?

Four common mistakes: sealing the cooler airtight, handling dry ice with bare hands, mixing “do‑not‑freeze” items without barriers, and transporting in unventilated spaces. Each one shortens hold time or creates real safety risks.

Design your SOP around prevention. Vent lids so CO₂ can escape. Use cryo‑gloves and eye protection. Separate chill‑only items with barriers or move them to gel/PCM zones. In vehicles, allow airflow—cracked windows are mandatory for long drives.

Do / Don’t snapshot

| Do | Why it works | Don’t | What goes wrong |

|---|---|---|---|

| Vent your container | CO₂ needs to escape | Seal it airtight | Lid deformation; pressure |

| Pre‑chill everything | Saves 3–5 lb on day one | Load warm contents | Burns through dry ice |

| Wrap the blocks | Slows sublimation | Touch items directly | Surface freeze damage |

| Keep car ventilated | Avoids CO₂ buildup | Run closed recirc | Headache/drowsiness risk |

Real‑world tips for you

-

Power outage (24–36 h): 10–15 lb/day for a 25‑qt, shaded; open rarely.

-

Meal kits (overnight): One wrapped block on top; fill voids; vented lid.

-

Backcountry (48 h): Two 10‑lb blocks; split placement; barrier over delicate foods.

Applied example: A small creamery used 12 lb in a 48‑qt cooler, pre‑chilled and paper‑wrapped. Result: solid product on day two, compliant marking for air segments, and no lid deformation.

2025 developments and trends in frozen logistics

The push in 2025 is toward validated packouts, smarter IoT temperature logging, and sustainable insulation that extends holds with less refrigerant. Carriers refreshed DG job aids, and the passenger dry‑ice limit remains 2.5 kg. Expect more PCM‑based lanes for chill ranges and lighter, longer‑lasting shippers for frozen flows.

Latest progress at a glance

-

Smarter monitoring: Affordable loggers with live alerts reduce surprise excursions.

-

Greener packs: Reusable shippers and better insulation cut refrigerant mass.

-

Compliance first: Clearer label/mark rules speed hub throughput.

Market insight: Growth in e‑grocery and specialty pharma keeps frozen capacity tight. Teams that validate and document their SOPs see fewer returns and faster handoffs at hubs.

Frequently Asked Questions

How long will a 48‑qt pack dry ice cooler hold frozen?

Plan 14–20 lb/day baseline; 28–40 lb total for 48 hours, then adjust for heat and opens. Pre‑chill for best results.

Should dry ice go on top or bottom when I pack dry ice cooler?

Top for frozen, bottom (with a barrier and regular ice) for chilled layers. This prevents freezer burn on sensitive foods.

Can I fly with a pack dry ice cooler?

Yes—up to 2.5 kg per passenger with airline approval and vented packaging. Mark “Dry Ice/Carbon dioxide, solid” and net kg.

What’s the safest way to dispose of leftovers?

Let dry ice sublimate in a ventilated area away from people and pets. Do not enclose or drain it.

Will dry ice damage my cooler?

Quality coolers tolerate it. Use a barrier layer to protect plastic liners and avoid brittle spots.

Summary and recommendations

Key points: To pack dry ice cooler well, pre‑chill, wrap blocks, fill voids, and keep packaging vented. Size 5–10 lb per 24 h per ~25‑qt and place ice on top for frozen, bottom (with a barrier) for chilled. For air segments, mark UN1845, add Class 9 label, and show net kg.

Next steps: Use the estimator to set daily pounds, draft a one‑page venting & labeling SOP, and run a pilot with a logger. If shipping by air, audit against your operator checklist. CTA: Book a Tempk lane review to lock your packout and reduce cost and risk.

About Tempk

We are a cold‑chain packaging and analytics team that designs practical, validated packouts. We pair lane modeling with qualified shippers and the right coolant mix to hit your targets with fewer touchpoints and lower total landed cost. Advantages: evidence‑based SOPs and rapid pilot‑to‑scale across food, e‑grocery, and specialty pharma.

Talk to us: Get a tailored plan or request a sample packout today.