Are Dry Ice Bags Compliant with IATA Rules in 2025?

When shipping perishables, pharmaceuticals, or biological specimens by air, the use of dry ice is common. However, dry ice is classified as a dangerous good, and shipping it improperly can result in fines, delays, or even confiscation. This article provides a comprehensive overview of IATA’s regulations, focusing on dry ice shipping, packaging, and compliance in 2025.

-

Understand the IATA classification for dry ice and why it matters

-

Learn the essential packaging and labeling requirements

-

Identify key compliance factors for dry ice bags

-

Discover the latest trends and updates in dry ice shipping compliance

What is IATA’s Classification for Dry Ice?

IATA classifies dry ice as UN 1845, Carbon dioxide, solid, under Class 9: Miscellaneous Dangerous Goods. This classification exists due to dry ice’s sublimation properties, where it turns into carbon dioxide gas. In confined spaces, this gas can displace oxygen and lead to asphyxiation hazards.

Dry ice must be packaged and transported according to Packing Instruction 954 as specified by IATA’s Dangerous Goods Regulations (DGR). These regulations ensure that dry ice is handled safely, preventing accidents and maintaining regulatory compliance. The 2025 update emphasizes clear packaging and labeling, with special focus on venting and weight limits.

Key Considerations:

-

Dry ice sublimates at −79°C, releasing carbon dioxide gas.

-

Proper packaging is vital to prevent dangerous pressure buildup from gas accumulation.

-

IATA rules allow up to 200 kg of dry ice in a cargo shipment but limit 2.5 kg for passenger baggage.

How Can You Ensure Dry Ice Bags Meet IATA Standards?

Ensuring dry ice bags meet IATA standards requires specific measures to handle safety and compliance. Here are the steps to make sure your shipments are fully compliant:

Step 1: Select the Right Packaging

Dry ice packaging must have ventilation systems that allow gas to escape safely. Sealed or airtight containers are not allowed as they can cause dangerous pressure build-up, potentially leading to rupture. Vented bags or containers with breathable membranes should be used.

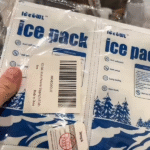

Many suppliers now provide vented dry ice bags that comply with IATA standards. These bags are designed to release sublimated CO₂ gas through permeable materials or vent holes. Additionally, using micropellet dry ice offers better temperature control and reduced pressure risk during transit.

Step 2: Labeling and Documentation

Correct labeling is a critical component of compliance. The dry ice bag must clearly display:

-

The UN number (1845) along with the words “Dry Ice” or “Carbon dioxide, solid”.

-

The net weight of the dry ice in kilograms.

-

A Class 9 hazard label indicating it is a miscellaneous dangerous good.

Documentation such as the Air Waybill must also include the UN number, shipping name, weight, and number of packages.

Step 3: Air Carrier Requirements

Different air carriers may have additional requirements for dry ice shipments. While IATA’s guidelines provide a global standard, airlines can implement variations. Always consult with the airline to ensure compliance with their specific policies. For instance, the maximum weight per package for dry ice can vary based on carrier-specific limits, even though the global limit is 200 kg.

What Are the Safety Concerns for Shipping Dry Ice?

Dry ice shipping, while essential for certain industries, poses significant safety concerns if not handled properly. The primary risk associated with dry ice is the release of carbon dioxide (CO₂) gas, which can accumulate in confined spaces.

Key Risks and Solutions:

-

CO₂ Buildup: Without proper ventilation, CO₂ gas can build up in the shipping container. This is especially dangerous in air cargo holds or confined spaces like aircraft cabins. Solution: Use bags with adequate venting to safely release the gas.

-

Frostbite: Dry ice is extremely cold, and direct contact can cause severe frostbite. Solution: Handlers must wear protective insulated gloves to prevent skin damage.

-

Packaging Failure: Without durable packaging, dry ice can cause leaks or explosions due to pressure buildup. Solution: Choose bags that are both leak-proof and able to withstand temperature fluctuations during transit.

Packaging Compliance Checklist:

| Requirement | Details | Why It Matters |

|---|---|---|

| Ventilation | Bags must allow CO₂ release through vents | Prevents pressure buildup and ensures safe transport |

| Labeling | Include UN 1845, weight, and hazard symbol | Helps handlers identify the contents and manage risks |

| Documentation | Air Waybill, hazardous goods declaration | Ensures compliance and avoids shipment delays |

| Temperature Monitoring | Use temperature sensors for perishable goods | Ensures the dry ice maintains the required temperature |

Latest Trends in Dry Ice Shipping Compliance (2025)

The dry ice shipping industry has seen some key developments in 2025, driven by both safety considerations and environmental concerns.

Technological Advancements:

-

AI-powered Temperature Monitoring: Companies are now using AI-driven systems to monitor and control dry ice temperatures in real-time. These systems can alert shippers if conditions deviate from the required ranges.

-

Sustainability: The trend toward more sustainable packaging solutions is growing. Manufacturers are incorporating bioPE liners and recycled CO₂ sources to lower the carbon footprint associated with dry ice production.

-

Improved Venting Solutions: New packaging materials and designs are being developed to enhance the efficiency of CO₂ release, while minimizing the risk of dry ice leakage.

Common Questions About Dry Ice Shipping

Q1: Can I ship dry ice in sealed packaging?

No, sealed packages are not compliant. The packaging must allow the release of CO₂ gas to prevent pressure buildup, which can cause rupture.

Q2: What documentation is required for dry ice shipments?

An Air Waybill listing the dry ice UN number, weight, and number of packages is necessary. A Shipper’s Declaration is only required if dry ice is used with other dangerous goods.

Q3: How much dry ice can I ship per package?

You can ship up to 200 kg of dry ice per package for cargo shipments. For passenger baggage, the limit is 2.5 kg per person.

Conclusion: Best Practices for Dry Ice Shipping

To ensure your dry ice shipments are compliant and safe, remember to:

-

Use vented packaging to allow CO₂ gas release

-

Ensure proper labeling and documentation

-

Stay up to date with 2025 IATA regulations to avoid penalties

By following these guidelines, you can ensure the safe transport of dry ice while complying with IATA regulations.

Next Steps:

-

Review your dry ice packaging to ensure proper venting and labeling.

-

Train your staff on the latest dry ice shipping practices and regulations.

-

Stay informed about regulatory updates and adopt the latest technology solutions to enhance compliance and safety.

About Tempk:

At Tempk, we provide top-of-the-line cold chain solutions, including IATA-compliant dry ice bags. Our packaging ensures that your products stay within the required temperature ranges, while meeting all regulatory standards. For safe and efficient dry ice shipping, contact our team for expert advice and customized solutions.