Shipping temperature-sensitive products like food, pharmaceuticals, or biological samples demands careful selection of the appropriate cooling method. When it comes to cooling solutions, gel packs and dry ice are two of the most commonly used options. In this comprehensive guide, we’ll delve into the differences between these cooling agents, the benefits and drawbacks of each, and the factors that will help you determine which is best suited for your needs.

-

Understand the primary differences between gel packs and dry ice

-

Learn when each method is most effective

-

Explore the 2025 cold chain shipping trends that will influence your decision-making

What Are Gel Packs and Dry Ice?

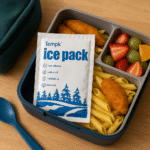

Gel Packs

Gel packs are flexible and reusable cold packs filled with a water-based gel that freezes to provide cooling during transit. They are commonly used for shipping refrigerated items like fresh food, pharmaceuticals, and medical supplies that need to stay cool but not frozen.

Key Characteristics:

-

Composition: A water-based gel sealed in a puncture-resistant outer layer.

-

Temperature Range: Typically, gel packs maintain temperatures between 32°F (0°C) and 40°F (4°C), ideal for items that require refrigeration.

-

Reusability: Gel packs are reusable and can be refrozen multiple times.

-

Safety: Gel packs are generally safe to handle, non-toxic, and do not release gases or require special ventilation.

Dry Ice

Dry ice is the solid form of carbon dioxide (CO₂), which sublimates directly from solid to gas at -109.3°F (-78.5°C). This makes it the go-to solution for products requiring deep freezing, such as frozen foods, certain pharmaceuticals, and biological samples.

Key Characteristics:

-

Composition: Solid CO₂, which sublimates into gas without melting into liquid.

-

Temperature Range: Dry ice maintains extremely low temperatures, ideal for deep freezing requirements, often reaching -109.3°F (-78.5°C).

-

Sublimation: As dry ice sublimates, it releases CO₂ gas, which requires careful packaging and ventilation to avoid safety hazards.

-

Regulatory Requirements: Dry ice is classified as hazardous material and subject to strict shipping regulations, including special labeling and ventilation requirements.

Gel Packs vs Dry Ice: Which Cooling Method Should You Choose?

Shipping Duration and Distance

For short-haul shipments or deliveries within a single day, gel packs are often sufficient, as they provide cooling for 6-24 hours depending on the conditions.

However, if your shipment is likely to be delayed or requires long-distance travel over several days, dry ice is typically the better choice. Dry ice’s longer cooling duration (up to 48 hours or more) can maintain freezing conditions over long trips or under higher ambient temperatures.

Temperature Sensitivity of Products

-

Gel packs are designed for items that need to stay cool but not frozen. They are best for products like fresh produce, dairy, and medical supplies that need to stay within a narrow temperature range of 2-8°C (35-46°F).

-

Dry ice is ideal for items that require sub-zero temperatures such as frozen foods, vaccines, and certain biological samples that demand ultra-low temperatures (below -18°C (0°F)).

Safety and Handling Requirements

-

Gel packs are non-hazardous and do not pose any significant risks. They are easy to handle without gloves, though it’s still advisable to wear them for prolonged exposure.

-

Dry ice, however, requires careful handling due to its extremely low temperatures and the risk of frostbite or burns. It also releases CO₂ gas during sublimation, necessitating proper ventilation and handling procedures. Always use insulated gloves and ensure adequate ventilation when handling dry ice.

Cost and Sustainability

-

Gel packs tend to be more affordable upfront and are reusable for multiple cycles, making them an eco-friendly choice for low-cost, short-term shipments. They are also less regulated, reducing paperwork and shipping complications.

-

Dry ice is more expensive both in terms of purchase price and shipping costs due to its hazardous material classification. However, for shipments requiring prolonged freezing or long-distance transport, dry ice may be worth the additional investment.

2025 Trends in Cold Chain Shipping

As cold chain shipping continues to evolve, several trends are shaping the future of how temperature-sensitive products are transported:

Sustainability Focus

Environmental impact is becoming a major concern, with an increasing shift toward sustainable cold chain packaging solutions. Companies are turning to biodegradable gel packs and plant-based packaging materials to minimize waste. Furthermore, advancements in dry ice production methods are reducing CO₂ emissions, helping companies meet environmental, social, and governance (ESG) goals.

Smart Packaging and IoT Integration

Smart sensors and IoT-enabled packaging are becoming mainstream in the cold chain logistics industry. Real-time tracking allows companies to monitor temperature, humidity, and location throughout the transit process, improving efficiency and ensuring products stay within safe temperature ranges. This innovation also helps comply with regulatory standards, ensuring products like pharmaceuticals and biologics maintain their integrity.

Automation and Robotics

The automation of cold chain logistics, including robotic handling in warehouses and packaging, is improving operational efficiency. Automated systems streamline packaging processes, enhance product safety, and ensure uniformity in the packaging of gel packs and dry ice.

Gel Packs and Dry Ice in Cold Chain Logistics: Advantages and Disadvantages

| Feature | Gel Packs | Dry Ice |

|---|---|---|

| Temperature Range | 32°F – 40°F (0°C – 4°C) | -109.3°F (-78.5°C) |

| Cooling Duration | 6-24 hours | 24-48 hours |

| Reusability | Yes, reusable | No, single-use |

| Cost | Lower upfront cost | Higher upfront cost |

| Regulatory Requirements | Minimal | High (hazardous material) |

| Safety | Non-hazardous | Requires special handling and ventilation |

Frequently Asked Questions

Q1: Can I use gel packs for shipping frozen food?

Gel packs are generally not suitable for frozen food that requires ultra-low temperatures. For frozen foods, dry ice is the better option to maintain sub-zero conditions.

Q2: Are gel packs environmentally friendly?

Yes, gel packs are often made from non-toxic materials and are reusable, which makes them an eco-friendly option. Many manufacturers are also incorporating biodegradable materials to reduce their environmental impact.

Q3: Can dry ice be reused?

No, dry ice cannot be reused. It sublimates completely and disappears as gas, so fresh dry ice must be used for each shipment.

Q4: What should I do if dry ice is not available?

If dry ice is unavailable, look for phase change materials (PCMs) or other cooling alternatives that can provide similar cooling effects, depending on your specific needs.

Conclusion and Recommendations

To choose the best cooling solution for your shipment, consider factors such as the temperature sensitivity of your products, the duration of transit, cost, safety, and environmental impact.

-

For chilled goods requiring moderate cooling, gel packs are cost-effective and convenient.

-

For frozen products or items requiring ultra-low temperatures, dry ice is necessary despite its higher cost and handling complexity.

By staying informed on the latest trends and innovations in cold chain logistics, you can optimize your packaging solutions to ensure safe, efficient, and compliant deliveries.

About Tempk

At Tempk, we provide reliable and eco-friendly cold chain solutions for businesses that require precise temperature control. Our gel packs and dry ice solutions meet industry standards and offer long-lasting performance to ensure your goods arrive at their destination safely and securely. Contact us today to explore our innovative cold chain shipping products and services.