Transporting temperature-sensitive medications requires meticulous planning and adherence to safety protocols. Dry ice bags provide an effective solution for maintaining the required cold chain during transit. These bags ensure that medications like vaccines, biologics, and insulin stay within the specified temperature range. This guide will explore the benefits, best practices, and regulatory requirements for using dry ice bags to ship medication safely and efficiently.

What is a Dry Ice Bag for Medication?

A dry ice bag is a specialized container designed to hold dry ice (solid carbon dioxide) during transportation. Unlike regular ice, dry ice sublimates directly from a solid to a gas, offering consistent cooling without leaving any residue. These bags are essential for transporting medications that require ultra-low temperatures, such as vaccines, biologics, and insulin, ensuring they remain at the optimal temperature during transit.

Key Features:

-

Insulation: Designed to minimize heat transfer, keeping the contents cold for extended periods.

-

Safety: Equipped with ventilation to allow the safe sublimation of dry ice gas.

-

Durability: Made from robust materials to withstand the rigors of transit.

-

Compliance: Meets regulatory requirements for shipping hazardous materials.

Benefits of Using Dry Ice Bags for Medication Transport

1. Extended Cold Retention

Dry ice keeps medications at temperatures as low as -78.5°C (-109.3°F), ideal for those requiring ultra-cold storage.

2. No Residue

Since dry ice sublimates directly into gas, it prevents moisture from forming, avoiding damage to packaging and ensuring that medications remain dry and intact.

3. Regulatory Compliance

Dry ice bags ensure compliance with international shipping regulations, such as those from the International Air Transport Association (IATA) and the U.S. Department of Transportation (DOT), including proper labeling and venting requirements.

How to Use Dry Ice Bags for Medication Transport

Step 1: Select the Appropriate Dry Ice Bag

Choose a dry ice bag that fits your medication containers comfortably, allowing enough space for the dry ice to sublimate without causing pressure buildup.

Step 2: Handle Dry Ice with Care

Always use gloves or tongs when handling dry ice to prevent frostbite. Ensure the bag has proper ventilation to allow carbon dioxide gas to escape safely.

Step 3: Pack the Medications

Place the medications in their original packaging inside the dry ice bag. Position the dry ice around the medication containers, ensuring even distribution for consistent cooling.

Step 4: Seal and Label the Package

Seal the dry ice bag securely, and affix the appropriate shipping labels. Label the bag with “Dry Ice” and any other required hazard symbols. Ensure compliance with all regulatory requirements.

Regulatory Requirements for Shipping Medications with Dry Ice

Shipping medications with dry ice involves adherence to strict regulations to ensure safety. These regulations govern labeling, packaging, and weight limits for shipments containing dry ice.

Key Regulations:

-

Labeling: Dry ice shipments must be labeled with “UN 1845” (for dry ice) and “Class 9” to indicate hazardous materials.

-

Weight Limits: Air shipments are generally limited to 5.5 kg (12 lbs) of dry ice per package.

-

Ventilation: Dry ice packages must be vented to allow gas to escape safely and avoid pressure buildup.

How Dry Ice Bags Help Preserve Medication Integrity

A dry ice bag ensures medications remain within their optimal temperature range during transportation, preserving their efficacy and stability. Dry ice prevents spoilage, moisture formation, and bacterial growth, which can compromise the quality of sensitive pharmaceuticals.

How Dry Ice Bags Maintain Medication Quality:

-

Prevents Spoilage: Consistent cold temperatures prevent degradation of medications, ensuring they stay effective.

-

Non-Water Residue: Dry ice sublimates into gas, preventing moisture buildup that could harm medications.

-

Reduced Bacterial Growth: Cold temperatures inhibit bacterial growth, maintaining the safety of biologics and other medications.

How to Ensure Safe Shipping with Dry Ice Bags

To ensure safe shipping, it’s important to follow best practices, such as proper sealing, insulation, and labeling. Regularly monitor the dry ice during transport and adjust for weather conditions.

Best Practices for Safe Shipping:

-

Pack in Advance: Allow sufficient time for dry ice to sublimate slowly to maintain cold temperatures.

-

Account for Weather Conditions: Extreme heat can cause dry ice to sublimate more quickly. Adjust insulation or dry ice amounts accordingly.

-

Check Regulations: Verify the latest shipping guidelines with the carrier to ensure compliance.

Dry Ice Bags vs. Gel Packs for Shipping Medication

Dry ice bags are superior for transporting medications that require freezing temperatures, such as vaccines and biologics. Gel packs are more suitable for medications that only need to remain cool, not frozen.

| Feature | Dry Ice Bags | Gel Packs |

|---|---|---|

| Temperature Control | Keeps items frozen and sub-zero | Keeps items cool, not frozen |

| Duration | Effective for 24-48 hours | Effective for 6-12 hours |

| Ideal Use | Biologics, vaccines, frozen medications | Fresh items, non-perishable medications |

| Regulations | Subject to strict shipping rules | No specific shipping restrictions |

| Cost | More expensive | Less expensive |

2025 Trends in Dry Ice Shipping for Medication

Trend Overview:

The use of dry ice bags for medication continues to evolve. Advancements in technology, such as real-time temperature monitoring and eco-friendly packaging, are improving the reliability and sustainability of pharmaceutical shipping.

Latest Trends:

-

Sustainability: Growing interest in green alternatives to dry ice, such as biodegradable packaging and sustainable shipping methods.

-

Smart Temperature Monitoring: Real-time temperature tracking to ensure medications stay within the required range during transit.

-

Hybrid Cooling: Combining dry ice with phase-change materials (PCMs) to extend hold times and reduce the need for excessive dry ice.

Frequently Asked Questions (FAQ)

Q1: How long can dry ice keep medication frozen?

Dry ice can maintain freezing temperatures for up to 48 hours, depending on the amount used and the packaging.

Q2: Is dry ice safe for shipping medication internationally?

Yes, but it requires proper labeling and packaging to comply with international shipping regulations. Always check with the carrier for specific guidelines.

Conclusion & Recommendations

Using a dry ice bag for medication is crucial for maintaining the cold chain during transport. By choosing the right dry ice bag, following safety protocols, and adhering to regulatory requirements, you can ensure that your medication reaches its destination safely and in optimal condition.

Actionable Steps:

-

Choose the correct dry ice bag based on your medication’s temperature needs.

-

Follow proper packaging practices to ensure safe and efficient shipping.

-

Monitor regulations regularly to stay compliant with the latest standards.

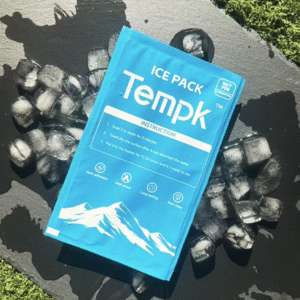

About Tempk

At Tempk, we specialize in cold chain packaging solutions for the pharmaceutical industry. Our dry ice bags ensure the safe transport of temperature-sensitive products, adhering to all shipping regulations. Need assistance with your pharmaceutical shipping? Contact Tempk for expert advice and solutions.