A dry ice pack for fish keeps seafood deeply frozen through parcel and air lanes when sized, packed, and labeled correctly. Plan 5–10 lb per 24 hours, position dry ice on top so cold air falls, and keep packages vented for CO₂. Target ≤32°F (0°C) for chilled and ≤−18°C for frozen arrivals to cut spoilage and claims. That approach ships frozen right.

-

How much dry ice pack for fish is needed by route time and insulation?

-

How to pack a dry ice pack for fish so temps stay below 32°F?

-

When to choose gel/PCM vs. a dry ice pack for fish for superchilled fish transport?

-

What UN1845 labels and airline/courier rules apply?

-

How 2025 trends (smart sensors, paper liners) reduce ice mass and cost?

How much dry ice pack for fish do you need for 24–72 hours?

Short answer: size a dry ice pack for fish at 5–10 lb per 24 hours in a quality shipper, then add 20–50% safety for summer or multi-hub routes. Full boxes and thicker insulation slow sublimation and extend hold time.

Why it works: Dry ice is −78.5°C and sublimates (no liquid), creating a cold reservoir that protects frozen fish for long transits. The more surface area exposed and the warmer the route, the faster it disappears—so pack tight and upgrade insulation before simply doubling pounds. Use a data logger to verify.

Dry ice pack for fish sizing calculator (quick start)

| Route & Box | Baseline (lb/24h) | Add-On Buffer | What it means for you |

|---|---|---|---|

| Overnight, premium shipper | 5–7 | +0–25% | Fewer pounds if box is full and pre-chilled |

| 48 hours, average EPS | 10–15 | +25–40% | Split across top and side pieces to avoid hot spots |

| 72 hours, hot lane | 15–25 | +40–50% | Consider VIP liners or PCM hybrid to cut total dry ice |

Pro tip: Place the dry ice pack for fish above product so the “cold dome” falls over fillets; keep a paper or corrugate spacer to prevent freezer burn.

How do you pack a dry ice pack for fish safely?

Use a “box-in-box” method: liner and spacer, tight-packed fish, dry ice on top, vented outer, and UN1845 labels. Keep packages non-airtight so CO₂ can escape; never tape all seams shut.

Step-by-step pack-out

-

Pre-freeze product and pre-chill the shipper.

-

Add a spacer so fish sit above condensate.

-

Load vacuum-sealed fish; fill voids to reach 80–95% box fill.

-

Place the dry ice pack for fish on top, wrapped in paper; add side PCM if superchilling.

-

Close the inner liner, leave designed vent paths, and label UN1845 with net dry-ice weight.

-

Insert a USB/BLE data logger to document time-at-temperature.

Box-in-box checklist (avoid the usual failure modes)

| Variable | Better Setting | Worse Setting | What it means for you |

|---|---|---|---|

| Insulation | ≥2″ rigid PU or high-R liner | ≤1″ EPS | Hours more hold time |

| Fill % | 80–95% full | Half-empty | Slower sublimation |

| Handling | Minimal door opens | Frequent opens | Protects the cold pool |

| Carrier path | Direct/overnight | Multi-hub/day+ | Add 25–50% ice margin |

Dry ice pack for fish vs. gel/PCM: which should you pick?

If delivery must be frozen, choose a dry ice pack for fish; for superchilled 0 to −2°C fish, use −21°C PCM and add a small dry-ice topper only for risky lanes.

| Cooling method | Temp range | Best for | Trade-offs | Your move |

|---|---|---|---|---|

| Dry ice pack for fish | ~−109°F (−78.5°C) | Frozen deliveries, 24–72h | Hazmat labels; vents required | Use when “frozen-solid on arrival” is non-negotiable |

| PCM −21°C bricks | −6 to −21°C setpoints | Superchilled quality | Higher upfront cost | Hybrid with small dry-ice topper |

| Gel packs (2–8°C) | Chilled items | Mixed baskets, live seafood | Cannot keep items frozen | Keep sauces/side items from freezing |

What rules and labels apply to a dry ice pack for fish?

Vent, label, and declare. Dry ice is UN1845 (Class 9 for air). Passenger flights often cap packages at 2.5 kg (5.5 lb); cargo services allow higher but require “Carbon dioxide, solid/Dry Ice,” UN1845, and net dry-ice weight on the package.

Labeling checklist

-

Mark UN1845 and show net dry-ice weight

-

Use non-airtight packaging with vents

-

Provide a 24-hour contact if the operator requires it

2025 trends shaping your dry ice pack for fish strategy

What’s new: Paper-based liners, low-cost BLE loggers, and reusable PCM cartridges are mainstream. Many shippers now meet SLA with fewer pounds of dry ice pack for fish, validated with logger proof.

At-a-glance advances

-

Paper liners: 48–72h performance with recyclability

-

Smarter monitoring: BLE/NFC loggers cut claims

-

Sensor freshness: Biosensors for fish quality grading

Dry ice pack for fish FAQs

How many pounds of dry ice pack for fish do I need for 48 hours?

Start with 10–20 lb depending on insulation and ambient heat; validate with a data logger.

Can I fly with a dry ice pack for fish?

Yes—use vented packaging, UN1845 labeling, and respect airline limits.

Is dry ice safe to handle?

Wear insulated gloves; ventilate rooms and vehicles to keep CO₂ safe.

What temperature is acceptable if fish thaws late in transit?

Keep at or below 40°F (4°C); closer to 32°F (0°C) is best.

How long does a dry ice pack for fish last?

Plan on 5–10 lb per 24 hours; better insulation stretches this.

Dry ice pack for fish summary and next steps

Key takeaways: Choose a dry ice pack for fish when frozen-solid delivery is essential. Size at 5–10 lb per 24 hours, place on top, vent, and label properly. For superchilled goals, use −21°C PCM with a dry-ice topper.

Action plan:

-

Pick a shipper for your longest lane.

-

Run 3 test shipments with loggers.

-

Standardize SOPs, labels, and add FAQ schema.

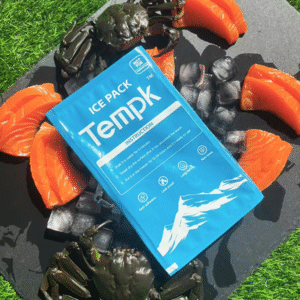

About Tempk

We build cold-chain packaging balancing performance, cost, and sustainability. Our engineers optimize seafood parcels with hybrid builds (PCM + dry ice pack for fish), 72-hour shippers, and logger validation. Clients cut claims by 30–40% after adopting standardized pack-outs.