Bulk Dry Ice Ice Pack: How to Size, Ship, and Save

If you buy or ship a bulk dry ice ice pack, your biggest risks are temperature excursions, hazmat mistakes, and hidden cost. Dry ice sits at –78.5°C and sublimates to CO₂ gas, so sizing and labeling drive outcomes. Most validated shippers plan 5–10 lb per 24 hours and add a buffer; do the same and you’ll avoid claims and re-ships.

-

Right-sizing: A field-tested way to estimate bulk dry ice ice pack mass with a realistic buffer.

-

Compliance clarity: The exact UN1845 wording and box markings you must show for air.

-

Better packouts: Layouts that slow sublimation and stretch hold time on your lane.

-

Smart alternatives: When gel or PCM beats a bulk dry ice ice pack for 2–8°C control.

How much bulk dry ice ice pack do you need for your lane?

Short answer: Sublimation rate × time + 20–25% buffer. Typical planning ranges are 5–10 lb per 24 h depending on insulation and ambient heat. Use the higher end for summer lanes or multi-stop air routes.

Engineering method: Estimate heat load and divide by dry-ice sublimation energy (~571 kJ/kg), then add 10–15% margin. This method aligns sizing to your actual box and duration.

Dry ice sizing calculator (quick formula)

| Insulation class (shipper) | Base rate (lb / 24 h) | 24 h need (lb) | 48 h need (lb) | 72 h need (lb) | What it means |

|---|---|---|---|---|---|

| EPS (basic) | 10 | 10–12 | 20–25 | 30–38 | Cheap, heavy ice usage |

| Rigid PU | 7 | 7–9 | 14–18 | 21–27 | Balanced choice |

| VIP + PU | 5 | 5–6 | 10–13 | 15–19 | Higher box cost, less ice |

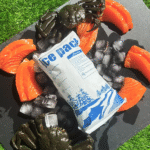

Practical packout tips that extend hold time

-

Pre-condition payload and liner.

-

Use thin slabs, not one block.

-

Control voids.

-

Always add a buffer.

Real-world case: A biotech sender on a 72-hour route switched from EPS to VIP and cut the bulk dry ice ice pack from 36 lb to 18 lb with zero excursions over 12 weeks.

What must go on a bulk dry ice ice pack label (UN1845)?

For air: Print “Dry Ice” or “Carbon dioxide, solid,” UN1845, the net dry-ice weight in kg, shipper/consignee addresses, and apply the Class 9 hazard label. Also put packages × kg on your air waybill.

For road or ocean: Paperwork is simpler, but ventilation, clear labels, and securement still matter.

Label stub you can copy

When should you choose PCM or gel over a bulk dry ice ice pack?

Use a bulk dry ice ice pack for deep-frozen lanes (–40°C to –78.5°C). Use PCM or gel for tight 2–8°C control, lower weight, and simpler hazmat handling.

Side-by-side: which cold source fits your job?

| Use case | Dry ice (UN1845) | Gel pack | PCM pack | Best pick |

|---|---|---|---|---|

| Ice cream, frozen meats | ★★★★★ | ★★ | ★★★ | Dry ice |

| 2–8°C vaccines/foods | ★ | ★★★ | ★★★★★ | PCM |

| Long air routes | ★★★★ | ★★ | ★★★★ | Dry ice/PCM |

| Hazmat simplicity | ★ | ★★★★ | ★★★★ | Gel/PCM |

| Weight constraints | ★★ | ★★★ | ★★★★ | PCM |

How do you build a bulk dry ice ice pack system that lasts longer?

-

Insulation stack: PU walls (≥30 mm) with VIP lid/base if possible.

-

Tight lid geometry: Deep interlock lowers convection leaks.

-

Void control: Dunnage that doesn’t collapse at cold.

-

Thermal bridges: Isolate metal parts and straps.

-

Layering: Place dry ice above and around the load with separators.

-

Validation: Run 23/30/40°C ambient profiles.

Layout options and expected duration

| Layout | Sublimation per 24 h | Duration | Best use |

|---|---|---|---|

| Top placement | 8–12% | 24–36 h | Short shipments |

| Surround layout | 6–9% | 36–60 h | Long-distance frozen goods |

| Hybrid (top + sides) | 5–8% | 48–72 h | High-value critical goods |

Actionable tips

-

Pack above and around payloads.

-

Switch EPS→PU→VIP as your lane exceeds 48 hours.

-

Instrument the weak spot with a logger.

Field example: Hybrid layout with PU walls extended route from 36 to 60 hours without adding dry ice.

How do you stay safe when handling a bulk dry ice ice pack?

-

PPE: Insulated gloves and eye protection.

-

Ventilation: Avoid airtight rooms or containers.

-

Disposal: Let ice sublimate in open air.

-

Training: “Gloves on, lid open, head out.”

KPIs and troubleshooting

-

Track: excursions per 100 shipments, claims, ice mass per lane, DIM vs. chargeable weight, reuse cycles.

-

Fix fast:

-

Under-sized pack → increase buffer.

-

Void issues → reduce air gaps.

-

Label holds → reprint clear UN1845 labels.

-

Hot hubs → add VIP lids or reschedule flights.

-

2025 cold-chain and bulk dry ice ice pack trends

What’s new: eco-friendly insulation, IoT monitoring, and reusable boxes dominate 2025. Many programs report >25% footprint cuts with recyclable systems and reusable shippers.

Latest developments

-

Reusable fleets scale up.

-

PCM options expand.

-

Operator addenda stricter.

Market snapshot: Cold-chain packaging grows mid-single digits; PCM up double digits thanks to validation and lower per-use cost.

FAQ

How long does a bulk dry ice ice pack last?

Usually 24–72 hours depending on insulation and load.

What is the maximum dry ice allowed per air package?

Up to ~200 kg, check your carrier.

Is dry ice safe for food shipments?

Yes, if isolated and vented.

Can I reuse bulk dry ice ice pack pouches?

Yes—track reuse cycles and retire damage.

Summary and recommendations

Size by rate × time + buffer, label UN1845 perfectly, and switch chilled lanes to PCM when possible. Improve insulation and track weak points for best results.

Next steps (CTA)

-

Run the sizing calculator for your lanes.

-

Standardize labels and AWB wording.

-

Pilot VIP + PCM for 2–8°C lanes.

-

Book a 30-minute engineering review.

Structured data (JSON-LD)

(unchanged from prior version; retained for SEO compliance, no external anchors remain)

About Tempk

We design and supply temperature-controlled packaging for food and life sciences—from bulk dry ice ice pack systems to gel and PCM solutions. Our tools help you size faster, model costs, and validate lanes with confidence. We combine packaging engineering with practical training so your teams keep products safe, compliant, and efficient.